Waterline Renewal Technologies. products

Trenchless Cleanout

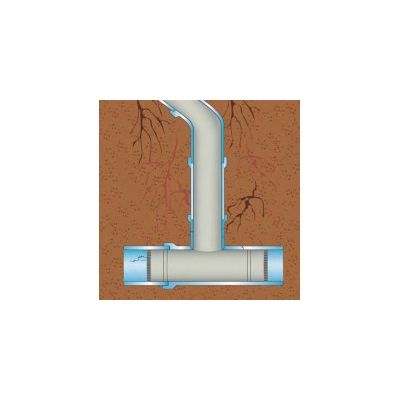

VAC-A-TEE - Trenchless Cleanout System

VAC-A-TEE is a trenchless cleanout installation system that is environmentally friendly, utility friendly, and installer friendly. Installed by means of hydro or vacuum excavation, the VAC-A-TEE system is a clean and safe method for installing a new cleanout, which provides access to the sewer lateral pipe for cleaning, lining, root removal, CCTV, etc. The system involves a patented PVC saddle, riser pipe of appropriate length, and proprietary hybrid adhesive/sealant. After a small diameter borehole has been created, the contractor applies the adhesive to the underside of the saddle and then snaps it onto the lateral pipe. Once the adhesive cures, it forms a watertight seal with the pipe, and a diamond core saw is then used to cut and remove the crown of the pipe. Finally, the borehole is backfilled, and sod is used to restore the landscaping, leaving the yard virtually untouched.

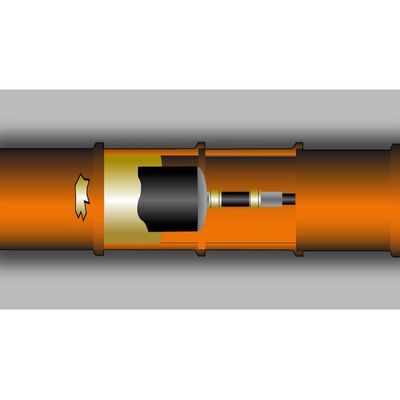

Perma-Liner - Sectional Point Repair Cured-In-Place-Pipe (CIPP) Rehabilitation System

Perma-Liner™ Sectional Point Repair Cured-In-Place-Pipe (CIPP) Rehabilitation System. The Perma-Liner™ Sectional Lining System is designed for 6” – 60” Diameter Pipelines. The materials are pulled into place through existing manholes and are ambient cured in 3 hours or heat cured in as little as 1 ½ hours. PLI Sectional Point Repair Materials can be installed safely, fast, and efficient. Installations average 1-5 installations per day. The Perma-Liner™ Sectional Point Repairs can be installed to repair 2FT–10FT areas on average but can accommodate lengths up to 30FT. The Sectional Point Repair materials are sold in kit form to eliminate waste, measuring and bulk storage. Installation equipment is compact and user-friendly.

Perma-Patch - Rehabilitates Pipes

Perma-patch is designed for 3″ to 24″ diameter pipelines with cracks, holes, and separation in joints.

Perma-Liner - Pull-In-Place Pipelining System

Cured-In-Place Small Diameter Pipe Repair Solution; The Perma-Liner™ Pull-In-Place Pipelining System is 100% trenchless. No digging up floors, landscaping, or tearing up walls. The versatility of this system allows lining 22’s, 45’s, sweeping 90’s and vertical stacks with ease, while stopping and starting anywhere in the line. Now you can service pipelines from 2″ – 8″ in diameter in less than a day and in most cases less than 5 hours with the new Perma-Liner™ Pull-In-Place Pipelining System. The Navi-Liner can also be supplied in 4″ – 6″ transitions without changing the structural properties of the liner.

Perma-Main Top Gun - Cured-In-Place-Pipe (CIPP)

Manhole to Manhole Inversion Rehabilitation System. The Perma-Main™ Top Gun™ lining system is designed for 8″ – 24″ Diameter Pipelines. The materials are air inverted through existing manholes and steam cured in as little as 1 ½ hours. The Perma-Main™ Top Gun materials can be installed safely, fast, and efficient. Installations average 300FT to 600FT in length. Transitions from 6″ – 8″ can be accomplished in a single installation. Materials are delivered prewet out, ready for installation. Installation equipment is compact and user friendly.

Mainline Rehabilitation

LMK Performance Liner - Sectional Inversion Process Renews Pipes

LMK’s Performance Liner Sectional process renews pipes from 6 to 42 inches in diameter and in continuous lengths up to 50 feet. The liner can be inverted anywhere in the pipe with no trimming or cutting. The result is a structural, root proof, water-tight seal. Performance Liner Sectional conforms 100% to ASTM F2599-11. Gasket sealing technology is used at the terminating points of the liner by embedding LMK patented Insignia™ Hydrophilic O-Rings between the liner and host pipe to ensure a water-tight seal. Compressible material is incorporated at the upstream and downstream ends of the liner for a smooth tapered transition to the old host pipe. During the positioning process there is no resin loss, because the liner is fully contained in the launch hose.

Launch Tanks

LMK - Lateral Launch Tank

The Lateral Launch Tank is designed for LMK`s lining through a clean out process. This tank can install CIPP liners from only one access point by inversion. Liners can be directed upstream or downstream and start and stop anywhere in the pipe.

Insignia

Insignia - O-Rings for Compression Seal

Insignia O-rings can be attached to a liner that is inverted into the pipeline to provide a compression seal at the termination points of the liner. This procedure remotely positions the O-rings between the host pipe and the liner tube or between a cured liner and a new liner (cold joint), sealing any annular space and providing a long-term flexible seal. Insignia O-rings can be utilized for upper end of lateral liners, a lateral liner overlapping a connection seal, and each end of sectional liners.

Insignia - Hydrophilic Connection Hat

The Insignia Hydrophilic Connection Hat is utilized to provide a positive compression seal at the main/lateral junction of a sewer collection system. This hat is a 360 degree sealing gasket that prevents water tracking behind the liner at the main/lateral junction of a collection system where the maximum amount of Infiltration and Inflow (I&I) occurs. The Insignia Hydrophilic Connection Hat creates a seal at the main source of infiltration ensuring that this sealing technology, along with a structural CIPP repair is the most effective solution for rehabilitating the main/lateral connection. The Insignia product line used in conjunction with CIPP lining is more than just a structural repair, it’s a water-tight, sealed system! The Insignia Hats are compatible with Inversion and Pull-in-place lining methods.

Lateral Pipe Repair

LMK T-Liner - Gasket-Sealing

LMK’s T-Liner is a one-piece homogenous main and lateral CIPP connection liner. T-Liner has a uniform wall thickness and incorporates compressible material at the upstream and downstream ends creating a smooth tapered transition to the host pipe. Both the mainline and lateral sections are formed as a structural cylinder that renews 18-inches and 360-degrees of the mainline and extends up the lateral pipe as one continuous lining. The T-Liner incorporates gasket-sealing technology that surrounds the main liner and the upper end of the lateral liner. These hydrophilic compression O-rings are embedded between the host pipe and the T-Liner providing a verifiable non-leaking connection (VNLC) with all pipe types including polyethylene. A permanent Lateral Identification Indicia is placed on the mainline lining which includes the building address and other pertinent information relating to raw materials used to form this one-piece structural T-Liner.