- Home

- Companies

- Watts Specialties

- Products

Watts Specialties products

Watts Machinery - Model W-60-20SM - Saddle-Miter Pipe Cutter for Pipe Cutting and Saddle Joints

The W-60-20SM Saddle-Miter Pipe Cutter from Watts Machinery is designed for cutting pipes up to 12 inches, making it ideal for applications such as stair rails, machine frames, and plumbing. This machine excels in producing precise 90-degree saddle joints, allowing any size branch to connect seamlessly to any trunk with the flexibility of setting miters to any practical angle. It comes equipped with an oxy-fuel torch, utilizing a Victor style 3-101 torch tip, and offers the option to rotate for desired weld bevels. The standard inclusion of a Rotary Ground and wiring for plasma use further enhances its versatility. Optional accessories make it compatible with a machine plasma system in addition to oxy-fuel capabilities. Furthermore, the W-60-20SM can be mounted as a table-top machine, providing additional flexibility for workshop setups. Its design aims to save time and labor costs by enabling repeatable and precise joint cuts.

Watts Machinery - Model W-60-20 - Straight Pipe Cutter

The W-60-20 Straight Pipe Cutter by Watts Machinery is a compact and versatile machine, ideal for educational settings and smaller workshops. This manually controlled device allows for the efficient preparation of pipe samples, making it highly suitable for training environments. It can handle pipes up to 12 inches in diameter, producing straight cuts with bevels quickly and precisely. The machine's internal chucking design is optimal for small pipes and supports both torch and plasma cutting. An upgrade from the previous W-60-12 model, the W-60-20 features a motor with double the torque, enhancing performance. Optional add-ons include a 32-pitch torch holder for plasma or oxy-fuel applications, and accessories such as scissor jacks, modular stands, and rollers for handling longer pipes.

Watts Machinery - Model W-50 - Tensile Weld Tester

The W-50 Weld Tester by Watts Machinery is a versatile and compact machine designed for destructive weld testing. It integrates compression, tensile, and bending tests into one efficient unit, fulfilling standards set by AWS, ASME, and API. The horizontally sitting design minimizes space usage while allowing a single operator to perform comprehensive weld qualification tests. The machine's test capabilities include full pipe tensile testing for pipes up to 1.5 inches in diameter, nick-break tensile testing for visible evaluation, and guided roller bend tests with varying diameters. It can handle materials with yield strengths up to 80K PSI, accommodating samples up to 12 inches in length. This makes the W-50 ideal for both training facilities and commercial applications where weld quality verification is crucial.

Watts Machinery Tools - Model W-250 - Tilt-Head Welding Positioner

The W-250 Tilt-Head Welding Positioner, a product of Watts Machinery, is a versatile tool designed for precise positioning of cylindrical parts. It can support and position parts up to 350 lbs vertically and 250 lbs horizontally, ensuring optimal operational efficiency by accommodating diverse weight requirements. The device features a controlled rotation speed through a user-friendly control panel, and its functionality can be initiated via an on/off foot pedal for convenience. Users can tailor the machine setup by opting for either a chuck or flat plate configuration, enabling custom clamping solutions. Durability is assured with its robust chucking jaws, ideal for quick, heavy-duty handling, enhancing production throughput. Operating on 110V, the positioner offers portability and ease of use across various work environments, making it a suitable choice for industrial applications.

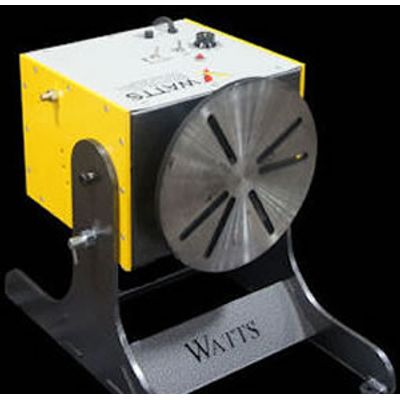

Watts Machinery Tools - Model W-70 - Welding Positioner

The W-70 Welding Positioner by Watts Machinery Tools is engineered to provide precise control for rotating workpieces during welding operations. It features a foot-pedal speed controller, allowing operators to maintain both hands on their work, optimizing welding performance. This positioner is designed to accommodate workpieces up to 12 inches using its internal jaws, providing flexibility for a wide range of welding applications. With the option of foot-pedal or panel control, it offers versatility in operation, making it suitable for various industrial environments. This device supports efficient workflow in welding processes, ensuring accurate positioning and rotation at controlled speeds. Intended for professional use, the W-70 promotes enhanced productivity and quality in welding tasks.