- Home

- Companies

- WEHRLE-WERK AG

- Products

WEHRLE-WERK AG products

Sequencing Batch Reactor ( SBR)

The economic pretreatment of wastewater has, over the last few years, gained increasing importance within industry. Wastewater pretreatment reduces disposal charges and likewise, the operating costs of a business. At the center of attention are space saving process that can accomodate wastewater streams that vary considerably with regards to flow. Therefore, SBR has, as a pretreatment process, achieved considerable acceptance in many different application areas such as the food, dairy and brewery industries, as well as in the treatment of wastewater with high concentrations of nitrogen compounds.

Adsorption Plants

Adsorption Plants For the removal of non-biodegradable COD and halogenated hydrocarbon (AOX) look no further than activated carbon. For example, wastewater from medicine production can be treated with a combination of biological and activated carbon processes, thereby ensuring the complete removal of endocrine mimicking compounds. At a chemical plant, activated carbon can be employed to remove non-biodegradable COD. Another application is the treatment of leachate from landfill sites.

BIOMEMBRAT - LE Process

The patented BIOMEMBRAT-LE process is suitable for the treatment of medium strengthed wastewaters e.g. wastewater from breweries, dairies, chemical and galvanising plants, the automotive industies and leachate.

Anaerobic Wastewater Treatment Plant

The fermentation of wastewater has gained increasing importance over the past few years. On the one hand higher organic loads can be treated, technically and economically, by anaerobc treatment. On the other hand it is possible to win back energy with the biogas produced by the fermentation process; a real benefit both economically and environmentally. For these reasons anaerobic wastewater treatment is installed in many industries, such as in the paper, milk and breweries.

BIOMEMBRAT - Model Airlift - MBR

BIOMEMBRAT®-Airlift is suitable for the treatment of weak wastewaters, such as municipal wastewater, black and grey wastewater from ships, wastewater from laundries, the catering trades, and hotels, as well as groundwater treatment.WEHRLE BIOMEMBRAT - High-Performance Membrane Bioreactor for Biological Wastewater Treatment System

The WEHRLE BIOMEMBRAT® high-performance membrane bioreactor is the compact wastewater treatment system for the sustainable and biological treatment of wastewater. With its modular design and volume and load-dependent control, the tried-and-tested wastewater treatment system can be adapted to individual circumstances. The membrane bioreactor demonstrates the strongest and most reliable cleaning power in any wastewater environment thanks to the consistent effluent quality with variable load peaks. The hybrid process consisting of energy-saving MBR technology and a tried-and-tested filter system cleans heavily contaminated wastewater of pollutants that are difficult to break down.

WEHRLE DIRECT-RO - Reliable Leachate Treatment With Flexible Reverse Osmosis System

The DIRECT-RO is a reverse osmosis container system that is used to treat leachate directly from the lagoon or landfill. The highly flexible and reliable 80 bar reverse osmosis system is the ideal solution for a high permeate yield at variable flow rates. With its compact design, simple operation and quick installation, the DIRECT-RO process combination is the perfect entry-level technology for the treatment of landfill leachate. Thanks to its modular design, the adaptable leachate treatment system can be expanded easily and cost-effectively and its performance can be further optimized with additional process solutions such as a BIOMEMBRAT® MBR. The leachate treatment system is available in three different sizes (S, M or XL) and as a rental system and covers inflow volumes of up to 260 m³/d. Thanks to a wide range of package options, the leachate treatment system can be easily adapted to local conditions and fully supported with the help of individual service packages.

WEHRLE P-XTRACT - Process Recovery of Phosphorus from Sewage Sludge

P-XTRACT® combines the energy recovery of sewage sludge with the recovery of phosphorus from sewage sludge from wastewater treatment plants. The P-XTRACT® process is used to create a marketable sewage sludge fertilizer with high plant availability that enables the valuable resource of phosphorus to be recovered. The P-XTRACT® process is based on the proven technology of fluidized bed incineration of sewage sludge with the addition of certain (earth) alkali additives and special fluidized bed material. The two-stage combustion in a reducing and oxidizing atmosphere increases the transfer of heavy metals into the gas phase, so that the P-containing ash in the flue gas is entrained as fly ash and separated from the flue gas at the highest possible temperatures > 700 °C. Heavy metals remain mainly in the gas phase and are separated at lower temperatures in the subsequent flue gas cleaning process.

WEHRLE BIODIGAT - Anaerobic Wastewater Treatment System

WEHRLE BIODIGAT® is a continuous biological wastewater treatment process that converts organic pollutants dissolved in water into valuable biogas. The reliable process combination purifies wastewater with a high organic load, for example from the food and beverage industry, and generates renewable energy in the form of biogas. After appropriate processing, this can be fed into the regular gas grid or used to generate heat and electricity. BIODIGAT® therefore makes a direct contribution to reducing the CO2 footprint, protecting the environment and producing biogas sustainably. Furthermore, anaerobic wastewater treatment with the BIODIGAT® can significantly reduce excess sludge production, which in turn significantly reduces sludge disposal costs.

Technologie

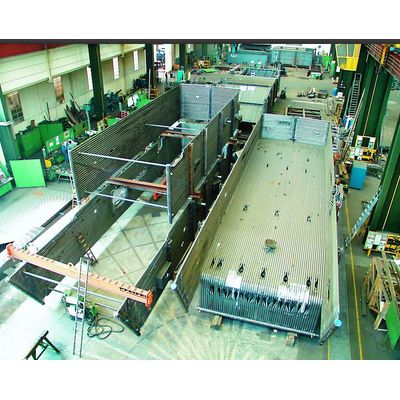

Wehrle-Werk - Water Tube Boilers

As internationally renowded producer WEHRLE is your specialist in terms of water tube boilers for hot water, satured steam and hot steam production. With decades of experience in conception, construction and maintenance we are your experienced partner regarding boiler plants.