Weiss ApS products

Weiss - Model T220T - Transport Worm Screw

The transport worm screw is designed for transportation of fine grained material (13x13x13 mm) of maximum 35 % moisture. The material, which is bio fuel, must be suited for this type of transport handling. The transport worm screw can be connected to the out-feeder type NFF-NFU or to a stoker. The transport worm screw is equipped with a direct drive, where the connection between the worm screw and the gear motor is assembled by a chain coupling.

Weiss - Model TS250 - Transport Worm Screw

Transport worm screw TS - 250 is used for transport of chips and shavings from the out-feeding system into, for example, a stoker. The worm is equipped with a gear motor of steady rotation. Inspection door, which is situated over the inlet, is pushed down by a spring. The inspection door is equipped with a micro switch which interrupts the worms operation when it is overflowed with material. The worm can be connected to the NFU or NFF stoker.

Weiss - Expansion Tank

Weiss expansion system is mainly used in connection with big heating plants and district heating plants. It is utilised to control excess water pressure from thermal expansion. The expansion system is delivered as a complete system consisting of tank and control system for maintaining the heating plant operation pressure. Pressure-free expansion tank which gives full utilization of the tank volume consequently saves space. The operation pressure is always the lowest possible and is independent of the water level in the tank. Minimal oxidizing of the boiler water which hinders corrosion and increases the plant`s service life. A proper size of the tank allows to accomodate the expansion of the water system thus protecting it from exceeding critical pressure limits.

Weiss - Model Type 220-W - Ash Worm

Ash worm type 220-W is used for emptying the ashes. The worm transports ashes from an ash chute to an ash container or ash bin. Ash worm consists of a worm driven by a gear motor of fixed speed, a worm pipe ø220 mm which is supplied with an inlet and an outlet, and a sealing bearing. The inspection door is placed by the outlet. The door is secured from opening while machine is in operation.

Weiss - Model KMP 120/200/200HD - Screw Out-feeder Gear

Screw out-feeder is used for automatic emptying of the circular silos with flat bottoms. The NFU out-feeder is used for feedeing out fine-grained material of maximum particles size of 13x13x13 mm and containing no foreign matter. The material used cannot cause corrosion; hence, its maximum moisture content cannot exceed 35% of its specific gravity.

Weiss - Boiler

WEISS boilers are specified, designed and produced in close cooperation with an experienced boiler produced in accordance with WEISS’ long experience within a large spectrum of bio fuels. The design is currently optimized to comply with customer wishes, still stricter demands within environmental measures and of course the unceasing efforts to produce new bio fuel types. Boiler sizes vary from 0.5 to approx. 20 MW for production of either water or steam.

Weiss - Multi Cyclone

WEISS designs and manufactures the multi cyclones used for the combustion plants. They are individually designed to each project by our project and design department. The multi cyclone separates dust particles from the flue gasses after the boiler. The multi cyclones can be supplied in more executions: Non-insulated, partly insulated and insulated all over. Depending on the size of the combustion plants and the quantity of ashes the multi cyclone can be supplied with ash bin or continuous ash outfeed to the ash conveyor system through a special rotary valve.

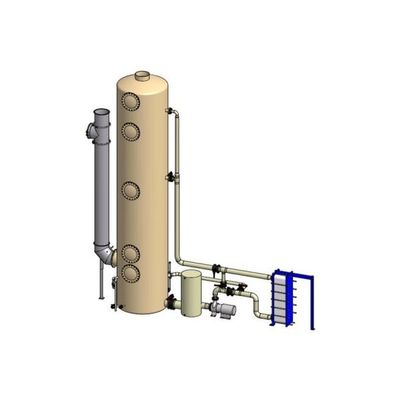

Weiss - Flue Gas Washer

WEISS has developed and designed a special flue gas condensing system. By the flue gas condensation the cold return water is pre-heated by means of the hot flue gas. This is contributing to a total high thermal efficiency of the plant. Further and by application of reciprocating action the flue gas is washed by the cooling process. This results in a highly efficient wash-out of solid particles reducing the particle emission to an absolute minimum. The condensation output can contribute with up to 20 % of the total system output.

Weiss - Flue Gas Filter System

The flue gas filter is used for separation of solid particles in the flue gas. Particle filters must be used if the particles cannot condensate. Technologically there are two options: The bag filter or the electro filter. Both options can only separate solid particles. The bag filter is a filter medium through which the flue gas is filtered whereas the electro filter separates the particles by inducing an electric current to the particles. The bag filter allows addition of possible reactive materials to the flue gas before the filtration. The reactive materials can be lime or active carbon. The electro filter allows higher flue gas temperatures.