Westeria Föerdertechnik GmbH products

Windsifter

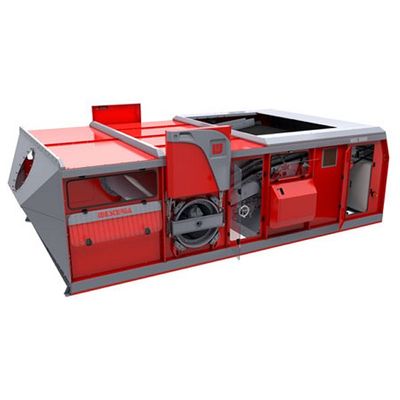

WESTERIA AirStar - Static Windsifter

The windsifters from Westeria are designed to be rugged, powerful and energy-efficient. A powerful method to separate heavy and light materials is what sets the patented Westeria windsifter technology apart.

WESTERIA AirLift - Static Windsifter

Operators of composting plants know the problem all too well: Organic household waste is often contaminated with foil and packaging waste. With the AirLift, Westeria®’s technicians and engineers have developed a unit that can be seamlessly integrated into existing systems. The AirLift system comprises three segments: The high speed transport belt, which feeds in the material at a speed of up to 4 metres per second. This is in turn connected to the AirWheel. We were able to rigorously build upon our years of experience in the wind sifter field in order to achieve clean separation of materials of virtually the same weight. And in conjunction with the AirWheel, the AirLift also perfectly demonstrates its abilities when processing PET bottles. Light plastics and label paper are perfectly separated. Wherever materials with a very similar, specific density need to be separated precisely, the AirLift is your ideal choice! Interested? Then speak to us!

Conveyor Systems

WESTERIA ChainCon - Chain Belt Conveyor

The tried and proven Westeria modular system was developed to be able to react flexibly and quickly to customer requirements. The unique chain belt conveyor system is geared towards every conceivable demand on the market. The chain belt conveyor is equipped with steel carriers, transporting every kind of feeding material easily. Westeria chain belt conveyors combine the highest „Made in Germany“- product quality with an extremely attractive price. Yet at the same time it provides sufficient space to be able to integrate special wishes and requirements into the existing system – in a flexible way and without any complications.

WESTERIA PipeCon - Conveyor Unit

The PipeCon is a logical extension to, and expansion of, Westeria Fördertechnik’s product range. The PipeCon is a conveyor unit for all types of bulk goods, with clearly defined grain sizes and a high conveying capacity of up to 500 t/h. The PipeCon’s conveyor belt in the upper run is pneumatically powered. Air nozzles positioned beneath the conveyor belt every 50 metres provide 2.2 kW blasts, therefore powering the belt. As a result, the entire system is extremely efficient and low maintenance, because hardly any wear occurs. Thanks to its design and special construction, large distances can be economically bridged thanks to a support spacing distance of up to 60 metres.

WESTERIA ChainCon - Chain Belt Conveyor

The tried and proven Westeria modular system was developed to be able to react flexibly and quickly to customer requirements. The unique chain belt conveyor system is geared towards every conceivable demand on the market. The chain belt conveyor is equipped with steel carriers, transporting every kind of feeding material easily. Westeria chain belt conveyors combine the highest „Made in Germany“- product quality with an extremely attractive price. Yet at the same time it provides sufficient space to be able to integrate special wishes and requirements into the existing system – in a flexible way and without any complications.

WESTERIA FlatCon - Flat Belt Conveyor

Wherever large quantities need to be processed such as in waste processing plants, the Westeria standard system has been proving itself for years. The flat FlatCon belt conveyor system which comes standard with a side seal is perfectly oriented on extremely tough everyday work. A rugged design and the use of low-wear materials have turned the Westeria belt conveyor system FlatCon into a classic. Its modular construction naturally means the flat belt conveyor FlatCon can be expanded at any time.

WESTERIA BendCon - Folding Conveyor

With the Folding Conveyor system BendCon, Westeria provides you with a rolling supported folding conveyor belt as the ideal solution for all "conveyor tasks" with an upward bend. The angle of the folding conveyor belt is aligned or adapted to your specific circumstances. The Westeria BendCon conveyor system has proven itself as a draw-off feeder for shredders, for instance. The sophisticated and rugged roller system and the corresponding belt leave no wishes unfulfilled and easily transport the feed material.

Bunker Systems

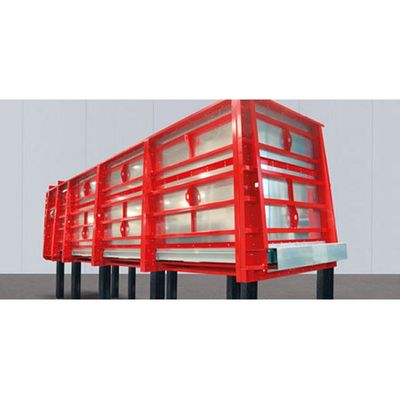

WESTERIA MovingFloor - Moving Floor Bunkers

Perfect down to the last detail - that`s the best way to describe the Westeria MovingFloor Bunker with its sophisticated modular principle. The intelligent and cost-effective structured series of these bunker systems provides the greatest possible flexibility within the standard product range. The bunker system is designed so that the MovingFloor Bunker can be expanded or upgraded at any time. The prefabricated modules enable delivery times within 5 weeks. The application areas of the MovingFloor Bunker bunker systems are also extremely flexible. From processing substitute fuels through compost up to building waste, everything is possible.

WESTERIA MobileFeeder - Bunker System

This latest bunker system innovation from Westeria is now an even better fit for companies that require a bunker system that can meet their individual needs. With its sophisticated modular principle it satisfies the various different bunker system requirements which exist. The main highlight of the new MultiFeeder bunker system is its linear transfer of the feed material. As a result, this bunker system takes up incredibly little space and can be easily integrated into existing systems. The bunker system comes in 4 designs. Depending on the material to be processed, we can offer you the MultiFeeder bunker as a chain conveyor, slat conveyor, belt conveyor or with pusher plates. Across all bunker designs, you choose between a 1,200 mm, 1,600 mm or 2,000 mm operating width, with a maximum bunker length of 12 metres.

Material Distribution Systems

WESTERIA DiscSpreader - Material Distribution Systems

Ingeniously simple, simply ingenious is a good way to sum up the tried-and-tested DiscSpreader material distribution systems from Westeria in just a few words. While the design may appear simple at first glance, at closer look it impresses with the most advanced technology in the area of material distribution, right down to the details. Even during non-linear material feeding the DiscSpreader ensures perfect, reliable material distribution of glass, wood, compost, scrap, residual sludge and commercial and domestic waste for all separation processes.