Westpak Inc services

Reliability

UV Accelerated Weathering

All materials and products used in the outdoor environment are constantly exposed to varying weather conditions, the effects of which can be detrimental over time. Although ultraviolet (UV) light makes up only about 5% of sunlight, it is responsible for most of the sunlight damage to polymer materials exposed outdoors. Add moisture to the hazardous effects of sunlight, whether it be from dew or rain, plus changes in temperature, and you have weathering occurring to your product.

Package Testing

Environmental Conditioning

One of the first test processes often required prior to conducting physical testing on the package, container, or packaging component being evaluated is Environmental Conditioning; this process brings the item to be tested into equilibrium with specific temperature and humidity conditions prior to testing.

Hazardous Materials

Hazmat Conditioning Test

Environmental conditioning is a process of subjecting a test specimen to various temperature and humidity conditions in order to determine the effect of these conditions on the test specimen. Often this conditioning is conducted prior to other tests such as mechanical or package performance testing in order that the test specimen be exposed to a full range of potentially harmful temperature and humidity levels.

Materials Analysis

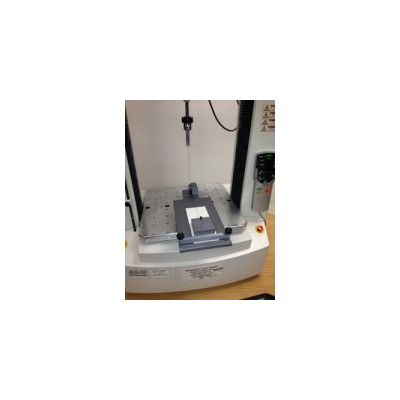

Coefficient of Friction

To determine the starting and sliding coefficients of friction for plastic film and sheeting, Westpak conducts the Coefficient of Friction (CoF) test per the ASTM D1894 test standard. The protocol allows five basic ways in which the test apparatus may be assembled. Westpak’s test setup incorporates a precision test sled apparatus, a Shimadzu load frame, and a very accurate load cell to generate test data.

Cold Chain

Environmental Testing

Environmental testing is a process of subjecting a test specimen to various temperature and humidity conditions in order to determine the effect of these conditions on the test specimen. Often, this conditioning is conducted prior to other tests such as mechanical or package performance testing in order that the test specimen be exposed to a full range of potentially harmful temperature and humidity levels.

Military/ Aerospace Testing

Salt Fog Testing

Salt Fog testing enables one to determine the quality and reliability of a product under corrosive atmospheric conditions.