Whittaker Engineering products

Marine- Turret Maintenance

Whittaker - Fairleaders and Gypsies

At Whittaker we design and manufacture fairleaders and gypsies in full accordance with DNV-OS-E301. We believe that on an FPSO the fairleaders should be able to withstand chain MBL, while seized, until the turret breaks out.

Whittaker - Turret Turning Grippers

Whittaker design and manufacture turret turning grippers for Tentech designed FPSOs, with all three FPSOs of this type in the British sector of the North Sea using our grippers. Our design offers a number of significant advantages over alternative designs resulting in extremely reliable and long-lasting products requiring comparatively little maintenance.

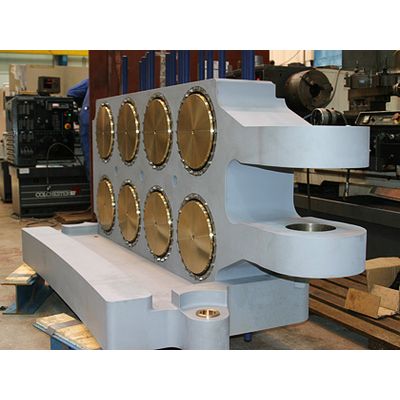

Whittaker - Turret Bearings

FPSO turret bearings present a number of known and predictable problems which can result in serious damage to bearing pistes, including bearing pads becoming detached in bad weather, ineffective greasing and oil leaks. At Whittaker we’ve developed proven, tested solutions to all these design problems.

Subsea -Diver Operated Tooling

Whittaker - Underwater Diver-Controlled Drilling Unit

Our diver-controlled drilling units will drill, tap, mill and cut. They are designed for work on pipelines, legs, wrecks, pontoons and caissons with drilling diameters of 10 to 200 mm, in scuba or hyperbaric applications. They’ve been tried and tested in constant use throughout the world.

Subsea - ROV Tooling

Whittaker - ROV Drills

We make, maintain and hire out ROV drill units built to our own design and specifications, using all the experience and knowledge we’ve gained over decades of subsea work. Our units can drill up to 150mm diameters without difficulty, using hydraulics and controls tailored to our clients’ vehicles and control systems. Fixing can be by mechanical clamps, suction feet or switchable permanent magnets.

Fabrication

Whittaker - Pressure Vessels

At Whittaker we design and manufacture vessels in carbon steel, duplex, stainless steel and aluminium. We can design to ASME VIII Division 1 and Division 2 (U & U2 Stamp), PD5500, BS EN 13445 (P.E.D. Cat I,II,III and IV under modules H & G). In addition to the manufacture of pressure vessels we are also authorised for vessel repairs on or off site under National Board ‘R’ stamp (ASME Vessels). By combining a machine shop and a fabrication shop under one roof, we can rebuild, refurbish and re-test heat exchangers and pressure vessels in a seamless cost-effective process.