WIDOS Wilhelm Dommer Sohne GmbH services

WIDOS - Rental Machines

You are interested in achieving fewer loss of working hours and less machine downtime? The solution is WIDOS rental machines and accessories. Our rental machine pool currently covers the dimension range from 20 - 1000 mm. There are different sizes of rental machines available. The rental charges are subdivided in daily-, monthly- and quarterly charges. Rental machines can help to avoid shortage or stoppage on the construction site. Projects can be finished on time. The majority of our welding machines and accessories can be provided for rent on short notice. Our machine pool currently covers the dimension range from 20 - 1000 mm and is regularly expanded.

WIDOS - Maintenance Services

Are you looking for a way to deliver reliable and secure work? The DVS (German Welding Association) recommends having welding equipment tested and maintained once a year. The maintenance of welding machines is carried out according to the DVS. The DVS recommends having welding equipment tested and maintained once a year by a skilled specialist. In order that your projects do not stand still during this time, there is the possibility to work with a rental machine in this period of time.

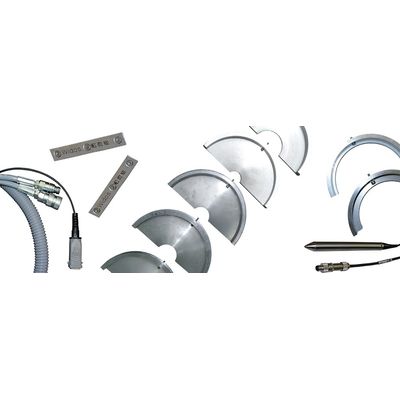

WIDOS - Original Spare Parts Services

You are in need of a spare part for your machine? Here at WIDOS, original spare parts are available for many many years. Spare part orders require a minimum order value of 100 EUR, excluding VAT.

WIDOS - Welding Tables

You are in need of information for your welding process e.g. regarding pipe diameter or bead height (welding parameters)? The welding tables for our machines can be downloaded as PDF file. Important information resp. parameters for the welding process are included in the welding tables. The welding tables are based on indications from the pipe manufacturers and the DVS (German Welding Association). The welding tables contain information regarding pipe diameter, pipe wall thickness, aligning pressure, bead height, heat-up time, change over time, pressure ramp time, welding pressure and cooling time.