WJ-Lean Technology Co., Ltd products

Karakuri System - Aluminum Tube

WJ-Lean - Aluminum Alloy Pipe

43 series aluminum pipes are typically used in environments with higher requirements for load-bearing capacity. The aluminum tube with a thickness of 1.7mm can provide the user with sufficient bearing capacity. Compared with the traditional lean pipe, the aluminum pipe has less resin coating. Because the supporting connectors are also aluminum materials, it is easy to recycle when doing waste treatment. Moreover, the surface of the aluminum pipe is treated with acid resistant aluminum, and it can be kept beautiful for a long time without maintenance. At the same time, the aluminum tube surface is also coated to reduce oxidation and keep the factory clean.

WJ-Lean - Anozied Aluminum Alloy Profile Tube

The uasge of 19 series aluminum lean tube are the same as 28 series tube. Retain edge aluminum alloy lean tube, the flat part can be installed with a back mounted parts box, or can be used as a barrier or partition, such as a aluminum lean tube racking, which is very convenient for hanging other parts. Aluminum tube and its supporting connectors are also aluminum materials, it is easy to recycle when doing waste treatment. At the same time, the aluminum tube surface is also coated to reduce oxidation and keep the factory clean.

WJ-Lean - Aluminum Alloy Profile Tube

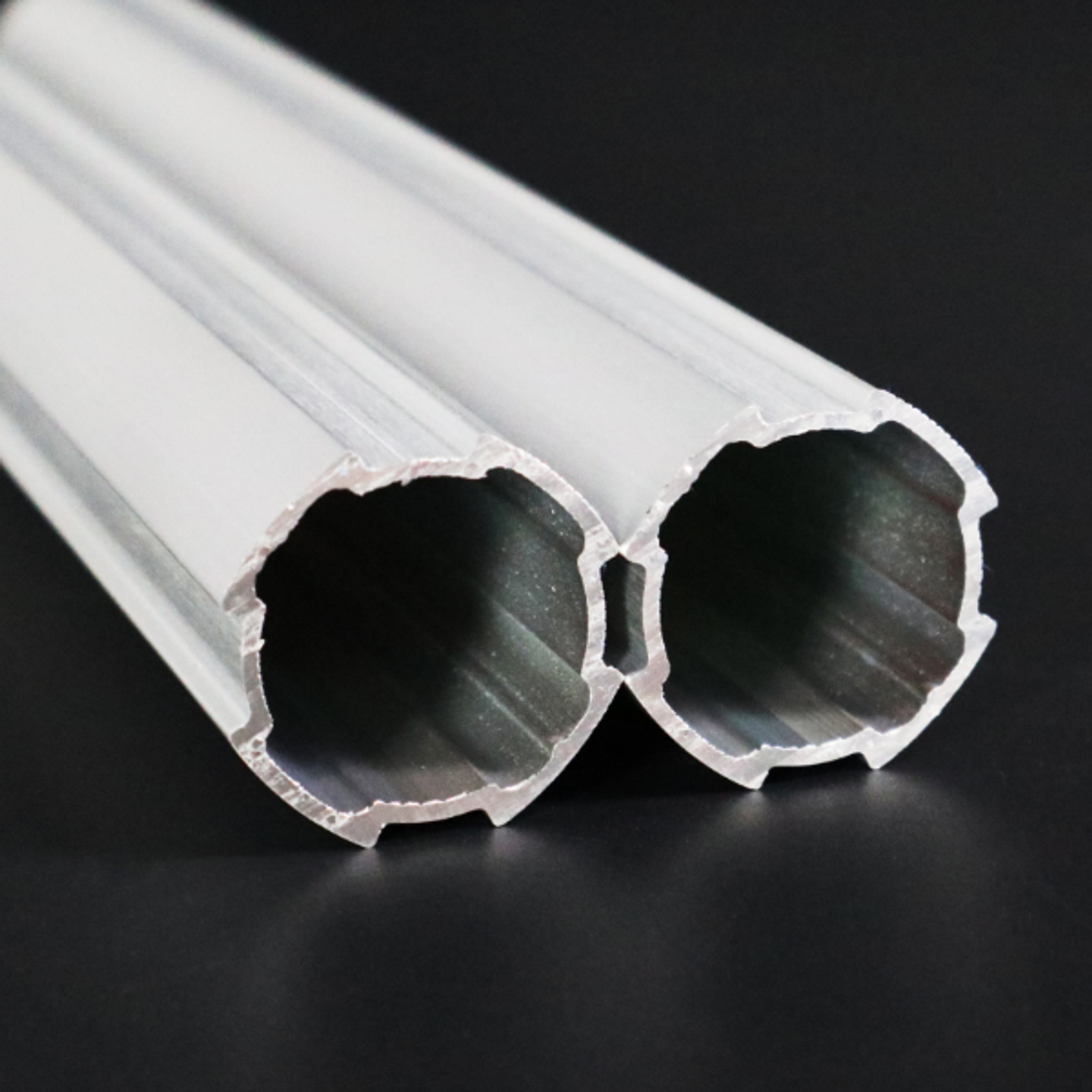

This aluminum profile is a frame of 28AT-7. There are buckles and grooves on the outer side of the aluminum profile, which can be used for connecting aluminum joints and other aluminum profile accessories. The number of pulleys on the inner side can be increased or removed according to actual usage. Its surface is smooth and burr-free, preventing customers from being injured during assembly. We can provide customers with other surface treatment services, such as painting, oxidation, etc.

Karakuri System - Aluminum Joint

WJ-Lean - Light Weight Handrail Joint

Aluminum handrail joint (28J-23) is very small in weight and volume, it clamps the two aluminum tubes tightly through the tightening of the bolts. Handrail joint has good bearing capacity and deformation resistance. Only a pair of screws and nuts are needed to fix the pipe and joint. The joint is made of 6063T5 aluminum alloy, which has good corrosion resistance and strength. In addition, in order to prevent users from scratching during use, WJ-LEAN’s joints are all subject to the grinding process, and at the same time, oil is sprayed on the joint surface.

WJ-Lean - Anozied Aluminum Alloy Profile Tube with Groove

The OD 43mm aluminum tube with groove can be connected by screws and aluminum alloy sliders to assemble shelves with different needs. It can be equipped with adjusting tools, so that the workbench can adjust the height at will. At the same time, the slot can also facilitate the storage of various tools. Aluminum tube and its supporting connectors are also aluminum materials, it is easy to recycle when doing waste treatment. At the same time, the aluminum tube surface is also coated to reduce oxidation and keep the factory clean.

Lean Pipe System - Tube

WJ-Lean - 1.0mm Thick Plastic Creform Pipe

ESD Lean pipe is composed of special composite steel pipes and plastic on the surface. The outer layer is generally PE PP and ABS. Lean tube with a thickness of 1.0mm can provide the user with sufficient bearing capacity. This product comes in a variety of colors for use in various items or per company’s image. The outer layer of plastic can effectively reduce the risk of injury in the workplace. At the same time, the inner steel pipe is subject to antirust treatment and is not easy to rust, which greatly extends the service life of the lean pipe. The tool rack built by lean pipe can reduce the learning time of parts and tools, and effectively improve the work efficiency of workers.

WJ-Lean - 28mm 2.0mm Thickness Stainless Steel Pipe

Stainless steel pipe is the second generation lean tube, and the thickness of these pipes is 2.0 mm, which means it has the best load-bearing capacity. In addition, stainless steel also has anti-corrosion and rust prevention functions. Which effectively extending the service life of stainless steel pipe racks. At the same time, it can adapt to the hardware joints of the first generation lean pipes.

WJ-Lean - 28mm 0.7mm Thickness Stainless Steel Pipe

Stainless steel pipe is the second generation lean tube, and the thickness of these pipes is 0.7 mm, which means it has the best load-bearing capacity. In addition, stainless steel also has anti-corrosion and rust prevention functions. Which effectively extending the service life of stainless steel pipe racks. At the same time, it can adapt to the hardware joints of the first generation lean pipes.

Lean Pipe System - Metal Joint

WJ-Lean - 90 Degree Metal Joint

90 degree metal joint need two pair of M6 * 25 bolts to complete the installation process. The equipotential line is stamped on both sides of the product to facilitate the user to measure the connection depth between the joint and the pipe during use. The joint is stamped from 2.5mm thick raw material. The stability of the structure can be guaranteed. After the joint is grinded, the burr on the joint surface can be greatly reduced or even completely cleared, effectively reducing the risk of injury to workers in the workplace. And the surface treatment of the joint adopts electroplating, which can effectively prevent its rusting and prolong the service life of the joint.

WJ-Lean - 180 Degree Two Side Metal Joint

The thickness of 180 degree two side metal joint(for connecting joint) is 2.5mm, which can ensure that it has a strong bearing capacity. Screw holes are also reserved on the surface of the product to facilitate the user to drive screws for fixation. Tighten the pipe clamp to the pipe. After the joint is grinded, the burr on the joint surface can be greatly reduced or even completely cleared, effectively reducing the risk of injury to workers in the workplace. The surface of the joint will be punched with stripes or dots during stamping, so as to better increase the friction between the joint and the pipe and make the whole structure more firm. The surface treatment of the joint adopts electroplating, which can effectively prevent its rusting and prolong the service life of the joint.