WOHLER Brush Tech GmbH products

Brushmaking Machines

Wohler - Model SBM 92 - Strip Brush Machine

The strip brush machine SBM 92 unites performance and precision. The modular machine design and countless additional modules allow the production of diverse strip brush types and forms, custom adapted to your requirements. Highest efficiency is guaranteed by the production capacity of up to 40 metres per minute. The fully automatic process runs autonomously. Fulltime operator attendance is not required. The quality of the products is totally convincing and can be additionally constantly monitored by means of optional inline measuring systems.

Wohler - Model SBM 840 - Strip Brush Machine

The strip brush machine SBM 840 with their countless additional modules allow the production of diverse strip brush types and forms. Customised to current and future production requirements the modular design offers a whole range of model versions, from a simple basic model up to a fully automatic production system.

Wohler - Model ATI 90 - Full Automatic Twist-In Machine

Fully automatic machine for the economic production of medium sized and densely filled twisted brushes with stub ends of high technical quality. Fill material is fed from hanks or spools, cut and directly processed. Trimming of the finished brushes is no longer necessary. The high production output of up to 10 brushes per minute cuts amortisation to an absolute minimum. Features like exceptional blade service times, automatic hank feeding and NC control guarantee efficient and economic production with maximal flexibility.

Street Sweeper Brush Machines

Wohler - Model PVM 100 I - Street Sweeper Roll Brush

PVM 100 I - Street sweeper roll brush segment production line for synthetic filaments fill and metal profile ring. The production line for classic street sweeper roll brush Segments with synthetic fill and metal profile ring. The automation of the process steps enhances efficiency and ensures a consistent and reproducible quality of the roll brush segments produced.

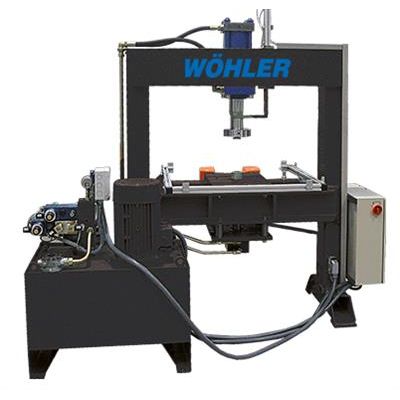

Wohler - Model HDT 30 - Hydraulic Press

The HDT 30 is a hydraulic press with special holder for segment production tools and higher speed for increased capacity. The press allows easy insertion of the fused strips from the PVM 87 W. The HDT 30 is fitted with a two-hand safety switch and the required stroke can be adjusted as required by means of limit switches.

Wohler - Model RWA 250 - Ring Rolling Machine

The metal band is fed by two driven profile rolls through an adjustable band guide. The diameter of the U- or V-shaped profile can be adjusted accordingly via hand wheel. The ready profiled and wound spiral is cut off in single segments. A transfer system places the spiral on the holding core, bringing it properly aligned into operating position. The process is started, the ring is clamped and calibrated to the nominal diameter on four points by the hydraulic cylinders.

Powerbrush Machines

Wohler - Model ZL 300 - Semi-Automatic Twist Knot Brush Machine

The semi-automatic ZL 300 is designed for the production of twist knot brush segments. The pre-punched disc is fed manually. The operator turns the disc to the required prosition, feeds the wire through the twisting head and disc and activates twisting by pressing the start button. The two-hand-operation ensures maximum safety.

Wohler - Model ZVA 320 - Twist Knot Brush Machine

The fully automatic, CNC-controlled twist knot brush machine ZVA 320 with hank feeding and powerful punching tool produces unique twist knot brush forms. This flexibility combined with the high power and the use of inexpensive naturally hard drawn wire make the ZVA 320 into a highly efficient twist knot brush machine. Hank feeding and integrated hole punching enable a fully automated series production. The wire is fed through one to four finished coiled hanks or single coils. The blank disks are automatically transferred from the magazine to the 2-station turntable.

Wohler - Model ZVA 600 - Twist Knot Brush Machine

Highly flexible, fully automatic twist knot machine for everything from small production lots up to large series. Knot filling and punching is done on one station, to ensure exact positioning of the twist knot holes. The machine covers the full range of brush sizes from large to small. Disks up to 150 mm in diameter can be automatically fed from magazine, larger disks can be fed by hand. Disks up to 450 mm diameter can be processed.