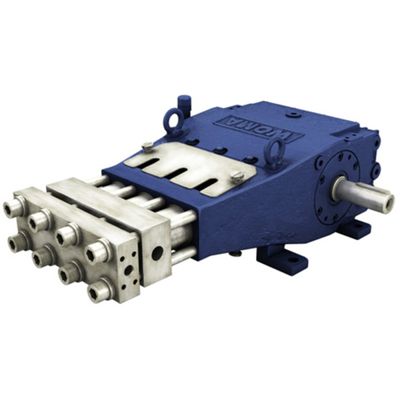

- Powerful High Pressure Plunger Pumps - M-Pump Series (3,000 Bar)

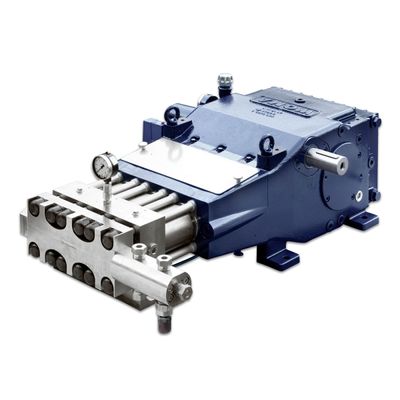

- Powerful High Pressure Plunger Pumps - Z-Pump Series (1,500 Bar)

- Powerful High Pressure Plunger Pumps - Y-Pump Series (1,000 Bar)

- Powerful High Pressure Plunger Pumps - 2-Pump Series (750 Bar)

- Powerful High Pressure Plunger Pumps - ARP-Pump Series (400 Bar)

- Powerful High Pressure Plunger Pumps - 3-Pump Series (250 Bar)

- High Pressure Water Jetting Systems - Electrical Units

- High Pressure Water Jetting Systems - Diesel Units

- High Pressure Water Jetting Systems - Hot Water Units

- High Pressure Water Jetting Systems - Individual Systems

- Waterblast Tools and Accessories - High-Pressure Guns - High Pressure Guns Up to 750 Bar

- Waterblast Tools and Accessories - High-Pressure Guns - High Pressure Guns Up to 1500 Bar

- Waterblast Tools and Accessories - High-Pressure Guns - High Pressure Guns Up to 3000 Bar

- Waterblast Tools and Accessories - High-Pressure Guns - Attachments

- Waterblast Tools and Accessories - Pipe and Tube Bundle Cleaning

- Waterblast Tools and Accessories - Surface Preparation

- Waterblast Tools and Accessories - Tank Cleaning

WOMA GmbH products

WOMA - EcoTherm 600 - Hot water trailer

With up to 95°C façades, small pipes, industrial flooring and other surfaces can be easily cleaned, oil and grease can be washed away and coating can be removed. The compact and light single-axle trailer can be brought to site with almost any middle class car. The easy to understand WOMATIC 4-Control with operational status monitoring, pressure-rpm regulation and pressureless circulation ensures high operational safety, low wear and tear, long service life, and last but not least, minimal fuel consumption. The tank system with 5 chambers including a safety trough hinders operational fluids escaping, such as fuel, oil or softeners.WOMA - Compact TD-C water turbo nozzle

With its lightweight, compact design, the Turbo Nozzle Compact (TD-C) complements the WOMA Turbo Nozzle family.

With a rotating nozzle carrier head, the TD-C is ideal for cleaning, surface treatment and removal tasks in ultra-high pressure applications from 500 to 3,000 bar and a maximum nominal flow rate of 45 l/min. It is suitable for cold and hot water up to 95°C.

Weighing just 1.3 kg and with a diameter of 54 mm, the TD-C can also be used in confined working environments and generates little vibration. The intuitive, three-stage sliding adjustment enables speeds from 500 to 4,000 rpm, allowing it to be used flexibly from cleaning to deep abrasion.

The robust design with high-quality stainless steel and a dirt-resistant sealing system ensures a long service life and minimises downtime. Maintenance and nozzle replacement are quick and easy thanks to the sophisticated design, even on the construction site.

WOMA - Compact TD-C water turbo nozzle

With its lightweight, compact design, the Turbo Nozzle Compact (TD-C) complements the WOMA Turbo Nozzle family.With a rotating nozzle carrier head, the TD-C is ideal for cleaning, surface treatment and removal tasks in ultra-high pressure applications from 500 to 3,000 bar and a maximum nominal flow rate of 45 l/min. It is suitable for cold and hot water up to 95°C.

Weighing just 1.3 kg and with a diameter of 54 mm, the TD-C can also be used in confined working environments and generates little vibration. The intuitive, three-stage sliding adjustment enables speeds from 500 to 4,000 rpm, allowing it to be used flexibly from cleaning to deep abrasion.

The robust design with high-quality stainless steel and a dirt-resistant sealing system ensures a long service life and minimises downtime. Maintenance and nozzle replacement are quick and easy thanks to the sophisticated design, even on the construction site.

WOMA - Compact TD-C water turbo nozzle

With its lightweight, compact design, the Turbo Nozzle Compact (TD-C) complements the WOMA Turbo Nozzle family.With a rotating nozzle carrier head, the TD-C is ideal for cleaning, surface treatment and removal tasks in ultra-high pressure applications from 500 to 3,000 bar and a maximum nominal flow rate of 45 l/min. It is suitable for cold and hot water up to 95°C.

Weighing just 1.3 kg and with a diameter of 54 mm, the TD-C can also be used in confined working environments and generates little vibration. The intuitive, three-stage sliding adjustment enables speeds from 500 to 4,000 rpm, allowing it to be used flexibly from cleaning to deep abrasion.

The robust design with high-quality stainless steel and a dirt-resistant sealing system ensures a long service life and minimises downtime. Maintenance and nozzle replacement are quick and easy thanks to the sophisticated design, even on the construction site.

Powerful High Pressure Plunger Pumps - M-Pump Series (3,000 Bar)

WOMA - Model Type 70M - High Pressure Plunger Pump

The Type 70M high-pressure plunger pump provides a max. working pressure of 3000 bar and a max. flow rate of 9,8 l/min. The ultra high pressure pumps of the M-series deliver pressure levels of up to 3000bar. The M-series pumps are ideally suited for tasks such as cutting, dismantling, decoating and derusting. With the built-in central valve design, these plunger pumps also have high volumetric efficiencies at high pressures. The carbide plungers used are extremely robust, provide long service life at very high pressures of up to 3000 bar, and can therefore guarantee low maintenance costs. They are also insensitive to sudden changes in temperature. The plunger guide ensures a long service life for the seal system.

WOMA - Model Type 150M - High Pressure Plunger Pump

The Type 150M high-pressure plunger pump provides a max. working pressure of 3000 bar and a max. flow rate of 34 l/min. The M-series pumps are ideally suited for tasks such as cutting, dismantling, decoating and derusting. With the built-in central valve design, these plunger pumps also have high volumetric efficiencies at high pressures. The carbide plungers used are extremely robust, provide long service life at very high pressures of up to 3000 bar, and can therefore guarantee low maintenance costs. They are also insensitive to sudden changes in temperature. The plunger guide ensures a long service life for the seal system.

WOMA - Model Type 190M - High Pressure Plunger Pump

The Type 190M high-pressure plunger pump provides a max. working pressure of 3000 bar and a max. flow rate of 34 l/min. M-series pumps are ideally suited for tasks such as cutting, dismantling, decoating and derusting. With the built-in central valve design, these plunger pumps also have high volumetric efficiencies at high pressures. The carbide plungers used are extremely robust, provide long service life at very high pressures of up to 3000 bar, and can therefore guarantee low maintenance costs. They are also insensitive to sudden changes in temperature. The plunger guide ensures a long service life for the seal system.

WOMA - Model Type 250M - High Pressure Plunger Pump

The Type 250M high-pressure plunger pump provides a max. working pressure of 3000 bar and a max. flow rate of 40 l/min. The M-series pumps are ideally suited for tasks such as cutting, dismantling, decoating and derusting. With the built-in central valve design, these plunger pumps also have high volumetric efficiencies at high pressures. The carbide plungers used are extremely robust, provide long service life at very high pressures of up to 3000 bar, and can therefore guarantee low maintenance costs. They are also insensitive to sudden changes in temperature. The plunger guide ensures a long service life for the seal system.

WOMA - Model Type 330M - High Pressure Plunger Pump

The Type 330M high-pressure plunger pump provides a max. working pressure of 3000 bar and a max. flow rate of 56 l/min. The M-series pumps are ideally suited for tasks such as cutting, dismantling, decoating and derusting. With the built-in central valve design, these plunger pumps also have high volumetric efficiencies at high pressures. The carbide plungers used are extremely robust, provide long service life at very high pressures of up to 3000 bar, and can therefore guarantee low maintenance costs. They are also insensitive to sudden changes in temperature. The plunger guide ensures a long service life for the seal system.

WOMA - Model Type 400M - High Pressure Plunger Pump

The Type 400M high-pressure plunger pump provides a max. working pressure of 3000 bar and a max. flow rate of 67 l/min. The M-series pumps are ideally suited for tasks such as cutting, dismantling, decoating and derusting. With the built-in central valve design, these plunger pumps also have high volumetric efficiencies at high pressures. The carbide plungers used are extremely robust, provide long service life at very high pressures of up to 3000 bar, and can therefore guarantee low maintenance costs. They are also insensitive to sudden changes in temperature. The plunger guide ensures a long service life for the seal system.