Wood Waste Control (Eng) Limited products

Industrial Shredders

Reinbold - Entsorgungstechnik Industrial Shredders

As part of our commitment to robust and reliable equipment, we’re proud to offer the Reinbold range of industrial chippers - with models suited for businesses of all sizes. Whether you’re involved in sustainable woodland work or exclusive cabinetry, our chippers provide a fast, efficient way of reducing your offcuts and waste timber to manageable woodchips. If you’ve invested in wood chippers or shredders before, you’ll appreciate that longevity and easy maintenance are key factors in any decision. The industrial chippers you see here have been selected for their exceptional performance and ease of accessibility.

Wood Waste Contror - Single Shaft Shredders

Single Shaft Shredders to shred (almost) everything! Our range of shredders are designed to shred all kinds of waste material, including hard and soft woods, chipboards, OSB and plywood panels, as well as construction timber.

Industrial Briquette Makers

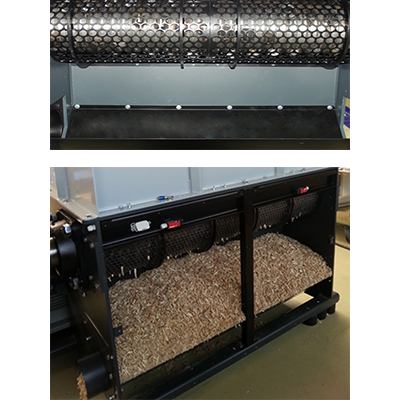

Wood Waste Control - Model B - Briquette Presses

Quality range of Briquette Presses helping you reduce your volume of waste! This range of briquette presses are able to briquette materials such as wood shavings, sawdust, wood chip or fine dust is mixed with others into stable, circular briquettes. The material would need to be smaller than 20mm and less that 18% moisture content before filling into the hopper. This can be via manual method or the briquetter could be placed under one of our extraction units to be fed automatically. It is possible to tailor these briquetting presses to the individual customer requirements, with controls on throughput, briquetter length, briquette diameter and hopper size. An agitator rotates in the hopper to ensure the correct quantity of material is fed into the pre-compression unit and moved from there with a filling slide into the pressing block.

Others Products

Wood Waste Control - Model FB - Bagging Extraction Units

Wood Waste Control - Model FD - Compact and Efficient Fine Dust Extraction Units for Woodworking

The FD range of collector units from Wood Waste Control is ideal for a wide range of fine dust applications with an extraction requirement of between 1,000 to 8,000 m3/hr. Each extraction unit is sold fully assembled and comes in a self-contained compact footprint, ideal to be installed inside or outside without losing valuable floor space. All FD extraction units come with a shaker unit that automatically cleans the filter bags, reducing the need for expensive compressed air systems and prolonging the lifespan & efficiency of the filters. New to 2016 is the new TH range adding extra filter area. Suitable for all wood products such as MDF, MFC, Hard Wood, softwood and more..

Wood Waste Control - Model WFB - Modular Bagging Unit

WFB modular filter unit suitable for wood, paper, metals and more. The modular design of the WFB makes it possible to configure the filter in many different formats to suit customer requirements. Another benefit to its modular construction is the flexibility for extension, allowing for future expansion. Waste can be transported and collected into bins, polythene collection bags or large canvas bags. Wood Waste Control has simplified the WFB design and construction techniques, managing to reduce the footprint of the unit without losing filtration capacity.

Wood Waste Control - Model WFB - Modular Silo Wood Dust Filter Unit

WFS modular filter unit suitable for wood, paper, metals and more. As with our WFB units the modular design of the WFS Silo filter makes it possible to configure the filter in many different formats to suit the customer’s requirements. The collected waste is discharged through a Rotary Valve unit and dropped pressure free directly into skip containers, storage silos, briquette presses , closed containers or similar. The WFS extraction unit can be sited on a purpose made steelwork structure or on the floor depending on individual requirements.