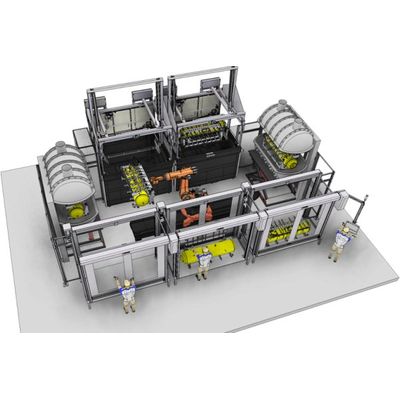

Worthmann Maschinenbau GmbH products

Helium Leak Test Systems

Helium leak test systems were first used in 1942 as part of the so-called Manhattan Project. This was the birth of helium leak test. Today, helium leak testers are among the most established and accurate methods of leak testing in series production and in the laboratory. In addition to helium leak testing in a vacuum, which requires a high vacuum in the mass spectrometer, helium leak testing under atmosphere using helium sensors is now also used.

Ultrasonic Leak Test for Hot Water Cylinders (boilers)

Not only the automotive industry has special quality requirements for its products, but other industries also manufacture products that place high demands on a corresponding tightness. Among other things, the leak test of hot cylinders (boilers) from the heating, building, water management and energy sectors should be mentioned here. The ultrasonic leak test offers several advantages. On the one hand, a leak rate of up to 1 ⋅ 10−4 mbar ⋅ l / s can be detected and, on the other hand, the leak can also be localized. Furthermore, a large number of variants can be covered with just one leak test system. A special innovation is the integrated interaction and combination of leak testing and an integrated pressure holding test.