WW Ekochem products

Termoplastic Elastomers

Ekochem - Termoplastic Elastomers

In response to market expectations, WW Ekochem has created a range of new generation thermoplastic elastomers under the Flexochem NG brand with reduced toxicity and improved properties.Flexochem NG is a thermoplastic elastomer resulting from the combination of an elastomer phase (SBS, SEBS, SEPS, etc.) with a thermoplastic phase. Specially selected components used in the production of Flexochem NG granules ensure high quality of the final product and customer satisfaction.

Plastic Additives

Masterbatch - Transparent Filler

Eko-Filler Nis a transparent concentrate of mineral filler in the form of white granules. It contains 80% of transparent non-toxic inorganic salts, well dispersed in metallocene LLDPE (m-LLDPE, LLDPE-C6) as a carrier, and additives improving processing properties.

Raw Materials - Plastics

Ekochem - Thermoplastic

Vulkaflex is a thermoplastic vulcanizate, called TPV, produced in an advanced process of dynamic vulcanization. This elastomer consists of a continuous polypropylene phase in which a vulcanized elastomeric phase obtained under high shear and temperature conditions is dispersed. TPV materials, unlike traditional rubber compounds, are in the form of granules and can be formed in continuous processes by extrusion or by injection. In addition, TPV, in contrast to vulcanized elastomeric mixtures, allow for the possibility of recycling and thus allow for the so-called recycling of finished products or post-production waste.

Machines

Ekochem - Granulation Lines Machine

Granulation lines with hopper from WWEkochem.

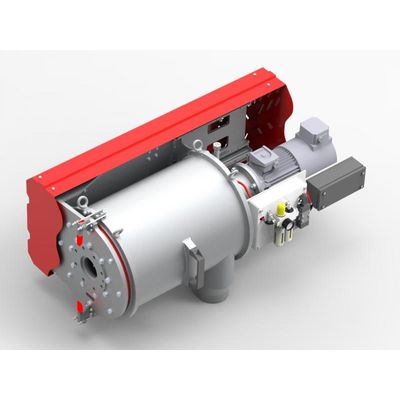

Parallel - Segmented Twin Screw Extruders

Segment twin screw extruders are used in processing to increase the quality of products and more effective plasticization of plastics, including difficult-to-process materials with additives, as well as for the processing of biodegradable materials.

Ekochem - Optical Sorters

Optical sorters for loose materials for separation of grinding and food - wherever the most important is the quality and purity of the material. The purification efficiency reaches 99.99%, thanks to the highest sorting accuracy material losses are limited to a minimum.

Ekochem - Pelletizing System

The cutting system in the cooling ring with pneumatic pressure is a granulation system of a wide range of polymer materials widely used in the PTS industry. The RW model is entirely the designed and implemented by WW Ekochem.

Ekochem - Conical Double Extruders

Conical double extruders are used for the extrusion process of thermally sensitive materials (like PVC).

Depending on the type, they are intended for various processing applications; for extrusion of PVC or other polymeric material profiles as well as pipes, plates and granulation.

Ekochem - Grinders

We use rotors with very efficient double-knife cutting technology in our mills. Grinders with different types of rotor are available with a length from 300 mm to 2000 mm and a diameter from 300 mm to 800 mm. The mills are equipped with a manual or hydraulic coffer opening system, which facilitates opening for maintenance of the cutting space, adjustment and fixing of knives, cleaning and changing of the sieve. The series has a charging hopper with newly developed silencing material, reliable technology and sound insulation.

Ekochem - Automatic Blow Moulding Machine

Our offer includes extruder-blowers for the production of packaging such as bottles, cans, containers, candle inserts, as well as industrial products for the automotive, sanitary or road industries.