Xinfeng Huihe Circuits Co.,Ltd. products

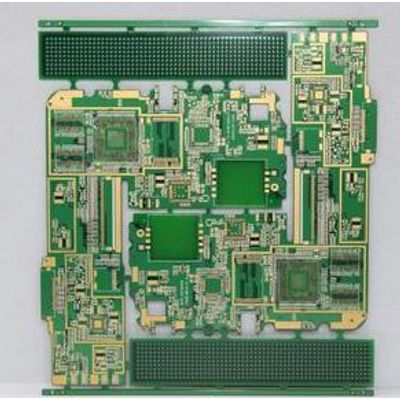

PCB Fabrication - Conventional PCB

High Speed PCB with Impedance Control

Impedance Control PCB refers to the PCB that needs impedance control. Impedance control refers to the “resistance” generated by a certain circuit layer under its high-frequency signal to its reference layer, and its signal must be controlled within the rated range to ensure that the signal is not distorted during transmission. Impedance control is to make each part of the system have the same impedance value, that is, impedance matching. Most high speed circuit boards currently have impedance control requirements. Therefore, it has also been said that a PCB board that does not have impedance control cannot be called a high speed PCB.

Gold Fingers PCB

Among the large-scale use of PCI and optical modules and cable sockets, the gold fingers PCB has been divided into: long and short gold fingers, broken gold fingers, and split gold fingers.

PCB Fabrication - Metal Core PCB

Aluminium Core PCB

Aluminium Core PCB is a metal-based copper clad laminate with good heat dissipation function. Generally, the single panel is composed of a three-layer structure, which is a circuit layer (copper foil), an insulating layer and a metal base layer. Also used for high-end use is designed as a double panel, the structure is circuit layer, insulation layer, aluminum base, insulation layer, circuit layer. A very small number of applications are multi-layer boards, which can be made of ordinary multi-layer boards combined with an insulating layer and an aluminum base.

Copper Core PCB

Copper core PCB is the most expensive one of the metal substrates, and its heat conduction effect is many times better than that of the aluminum substrate and the iron substrate. It is suitable for high-frequency circuits and regions with high and low temperature variations and the heat dissipation and architectural decoration industries of precision communication equipment.

Ferrum Core PCB

The Ferrum Core PCB is a metal heat sink substrate applied to high-end motors, high-end products and motors. It is widely used in the market. The hardness of the Ferrum Core PCB is much larger than that of the Aluminium Core PCB. It is difficult for general manufacturers to master. The technology, cost cost and scrap rate are relatively high.

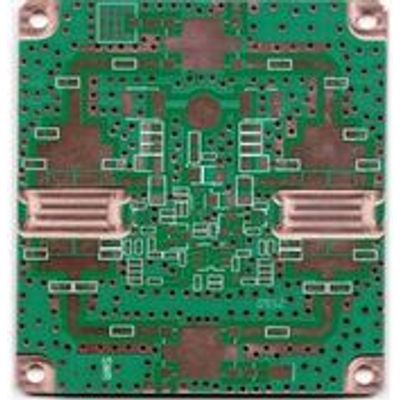

PCB Fabrication - High Frequency PCB

Rogers - High Frequency PCB

Supporting the military is something PCBSky is very proud of, and we were contracted to assemble a PCB for use in a military communication`s application. The RF PCB assembly used Rogers 4350, Rogers 4003,RT5880 material, and the board required surface mount technology for the double-sided assembly that featured 250 placements. Board specs included 3 layers, standard vias, and 1 panelization. Final measurements came to 8 × 5.75 in. We performed final testing using automated optical inspections and x-ray inspection before delivering product to the customer.

PCB Fabrication - Flexible PCB

Single Sided Flexible PCB

After the completion of the circuit, the single-sided PI-clad material is covered with a protective film to form a flexible fpc with only a single layer of conductor.

PCB Fabrication - Blind & Buried VIA Hole PCB

Blind & Buried PCB

HDI PCBs, one of the fastest growing technologies in PCBs, are now available at PCBSky. HDI PCBs contain blind and/or buried vias and often contain microvias of .006 or less in diameter. They have a higher circuitry density than traditional circuit boards. There are 6 different types of HDI PCBs, through vias from surface to surface, with buried vias and through vias, two or more HDI layer with through vias, passive substrate with no electrical connection, coreless construction using layer pairs and alternate constructions of coreless constructions using layer pairs. HDI any-layer printed circuit boards are the next technological enhancement of HDI microvia printed circuit boards: all the electrical connections between the individual layers consist of laser-drilled microvias. The main advantage of this technology is that all the layers can be freely interconnected. To produce these circuit boards, PCBSky uses laser-drilled microvias electroplated with copper.

PCB Fabrication - PCB Assembly

PCB Assembly

PCBSKY is a national enterprise focusing on PCB and PCBA manufacturing for 8 years. The company has a strong engineering team and a professional electronic component procurement team to serve many domestic and foreign automotive electronics, medical electronics, power communication, industrial automation and smart home. Our customers are from various industries, and PCBSky is a one-stop manufacturing service provider integrating PCB manufacturing, electronic component acquisition, chip processing and test assembly.

PCB Fabrication - Rigid-Flex PCB

Rigid-Flex PCB

The Rigid-flex PCB is a flexible circuit board and a rigid circuit board, which are combined by pressing processes and the like according to the relevant process requirements to form a circuit board having FPC characteristics and PCB characteristics.