Yixing Huading Machinery Co.,Ltd. products

Separator

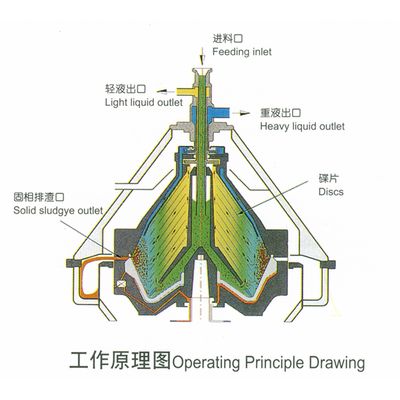

Disc Stack Centrifuge

The disc stack centrifuge, is also known as a disc bowl centrifuge or disc stack separator, is a type of centrifuge that has a series of conical discs which provides a parallel configuration of centrifugation spaces. The disc stack centrifuge is used to remove solids (usually impurities) from liquids or to separate two liquid phases from each other by means of an enormously high centrifugal force. The denser solids or liquids which are subjected to these forces move outwards towards the rotating bowl wall while the less dense fluids move towards the centre. The special discs (known as disc stacks) increase the surface settling area which speeds up the separation process. Different disc designs, arrangements and shapes are used for different processes depending on the type of feed present. The concentrated denser solid or liquid is then removed continuously, manually or intermittently, depending on the design of the disc stack centrifuge.

Self-Cleaning Separator

Many processes require solids to be discharged intermittently during operation, or for processes with liquids containing higher solids content (up to approx. 10%) the intermittent solids discharge separator is an ideal solution. As with disk separators with solid-wall bowl, the disk separators with self-cleaning bowl are equipped with a stack of conical disks to create a large equivalent clarification area within a relatively small bowl volume. These separators are likewise available as versions for clarification and separation. Separators with self-cleaning bowl are able to periodically discharge the separated solids at full speed. Designed with a unique hydraulic system below the separation space in the bowl which forces the sliding piston to drop down, thus opening the solids ports at the bowl periphery at preset intervals. This provides what is known as a self-cleaning effect when the solids are removed all at once during operation.

Decanters

Disc Decanter

The Disc Decanter effectively combines the respective advantages of decanters and separators in one machine: a disc stack ahead of the liquid outlet in the decanter bowl provides additional, highly efficient secondary clarification of the liquid phase. With the integral disc stack, the relevant ultrafine particles are separated and then returned to the decanter’s solids chamber and discharged along with the solid matter. In this way a whole new dimension of economic efficiency is obtained. With the Disc Decanter a previously unobtainable dry residue can be attained, which brings about a significant reduction in drying costs. The decanter capacity doubles, process stages become superfluous and both space requirement and capital and running costs fall.

Clarifying Decanter

Clarifying decanter centrifuge is most often used for clarification of liquid containing high concentrations of solids, removing solids from liquid. A clarifying decanter centrifuge is a sedimentation centrifuge for separation of suspended solids from one liquid. The characteristic which distinguishes a decanter centrifuge from other types of centrifuges such as disc stack separators is that it has a cone-cylindrical rotor equipped with a conveyor for continuous unloading of sedimented solids. Clarifying decanter centrifuges are used in a wide range of applications where their ability to achieve both good clarity and low moisture in the discharged solids is appreciated. They are very versatile as they can handle both large and small particles as well as a wide variety of solids concentrations.

Tubular Centrifuges

Tubular Centrifuge

High speed separation & clarification. GF series Tubular Centrifuge from Huading Separator is a high speed solid bowl type machine for continuous separation of two immiscible liquids with density difference. This centrifuge is also used to separate small quantity of impurities from liquids. The tubular centrifuge is consisted of frame body, driving device, bowl and motor. GF tubular centrifuge is designed to separate two (2) immiscible liquids of differing densities. The high centrifugal force generated causes the high density liquid to migrate toward the tube wall while the lower density liquid is displaced to the center of the tube. The separated liquids are then discharged at the top of the tube with dedicated outlets.