Yurcent Environmental Technology Co., Ltd. products

Square RTO with Rotary Valve

Yurcent - Customizable Square Rotary Valve Regenerative Thermal Oxidizer (RTO)

A Regenerative Thermal Oxidizer (RTO) operates by oxidizing combustible exhaust gases into harmless oxides and water at high temperatures. The goal is to purify the exhaust air while recovering heat produced during the oxidation process, creating a more energy-efficient and environmentally friendly operation.

Yurcent - Square Regenerative Thermal Oxidizer (RTO) with Rotary Valve

RTO, also known as regenerative thermal oxidizer, functions based on the principle of oxidizing the combustible exhaust air into corresponding oxides and water at an high temperature. This process is designed to purify the exhaust and effectively recycle the heat generated during the decomposition of the exhaust air. The primary objective is to not only eliminate harmful substances but also make the most of the energy released, contributing to a more efficient and environmentally friendly operation.

Bed RTO

Yurcent - Traditional horizontal 3-Bed Regenerative Thermal Oxidizer (RTO) with Poppet Valve

The Bed RTO is traditional type of RTO, usually equipped with 3 regenerative chambers. If the waste gas volume is large, 5 or 7 regenerative chambers can also be equipped. The core principle underlying the operation of Regenerative Thermal Oxidizer (RTO) revolves around the oxidation and decomposition of flammable exhaust gases into their constituent oxides and water vapor at high temperatures. This sophisticated environmental control technology not only purifies the exhaust gases but also captures and reuses the thermal energy generated during the gas breakdown process, thereby achieving a dual benefit of pollution control and energy conservation.

Classic Rotary Valve RTO

Yurcent - Classic Vertical Round Regenerative Thermal Oxidizer (RTO) with Rotary Valve

The Rotary Valve Regenerative Thermal Oxidizer (RTO), commonly referred to as a rotary valve RTO, operates by oxidizing combustible exhaust gases into their corresponding oxides and water at high temperatures. This process not only purifies the exhaust but also recovers the heat generated during the decomposition of the exhaust gases. The system achieves an exhaust decomposition efficiency of up to 99.5% and a heat recovery efficiency exceeding 95%.

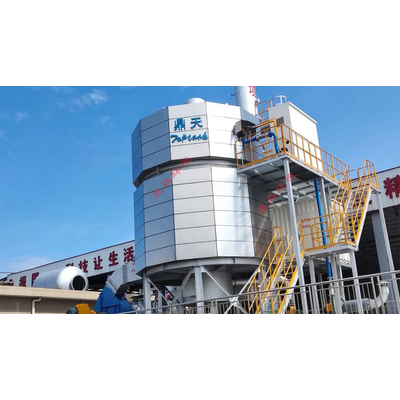

Top-Tank Rotary Valve RTO

Yurcent - High End Top-Tank Rotary Valve Regenerative Thermal Oxidizer (RTO)

Yurcent`s Toptank series, a high-end rotary Regenerative Thermal Oxidizer (RTO) product line, represents the pinnacle of technological innovation in the industry. This series has achieved world-class standards in quality, offering market users a premium choice. By integrating advanced technology, the Toptank series supports businesses in their transition to sustainable practices, ensuring a balanced approach to economic growth and environmental responsibility.

Zeolite Rotor

Yurcent - Zeolite Rotor

The zeolite rotor system is ingeniously divided into three distinct sections: the adsorption zone, desorption zone, and cooling zone. This design allows for an efficient and continuous purification process of low-concentration waste gases. As contaminated air passes through the adsorption zone, volatile organic compounds (VOCs) are effectively captured by the zeolite material. The purified air is then released into the environment. Once the zeolite rotor reaches its saturation point, it transitions to the desorption zone. Here, a small volume of high-temperature hot air, typically ranging from 180 to 220 degrees Celsius, is introduced to release the trapped VOCs and regenerate the rotor`s adsorption capacity. Following this, the rotor moves into the cooling zone, where it cools down before re-entering the adsorption zone to continue capturing VOCs. This cyclical process ensures uninterrupted purification of waste gases.