Zhejiang BW Industry Co., Ltd products

PEEK Polymers

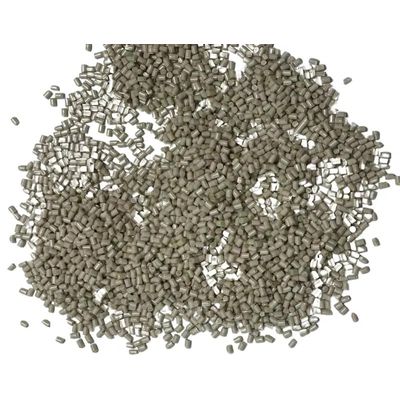

BW-Industry - Polyether Ether Ketone (PEEK) Granules

Polyether Ether Ketone (PEEK) 90 series includes PEEK 90P,PEEK 90G,PEEK 90GL30,PEEK 90GL60,PEEK 90CA30,PEEK 90HMF30,PEEK 90HMF40, which is a high performance engineering plastics, ultra-low viscosity resins, its MVR index is 100~130, the main processing methods are extrusion, molding, injection molding, and thermoforming, and 3d printer peek material. MVR index of 100~130, the main processing methods are extrusion, molding, injection molding, and thermoforming, and 3d printer peek material.

BW Industry - Polyether Ether Ketone (PEEK) Granules & Powder

Polyether Ether Ketone (PEEK) 150 series includes PEEK 150P,PEEK 150PF,PEEK 150UF10,PEEK 150G,PEEK 151G,PEEK 150GL15,PEEK 150GL20,PEEK 150GL30, PEEK 150CA30,which is a high performance engineering plastics, ultra-low viscosity resins, its MVR index is 70~90, the main processing methods are extrusion, molding, injection molding, and thermoforming, and 3d printer peek material.

BW-Industry - Polyether Ether Ketone (PEEK) Granules

Peek 450 Series High performance thermoplastic material, unreinforced PolyEtherEtherKetone (PEEK), semi crystalline, granules for injection moulding and extrusion, standard flow, FDA food contact compliant, colour natural/beige and black.

BW-Industry - Polyether Ether Ketone (PEEK) Granules & Powder

Polyether Ether Ketone (PEEK) 650 series includes PEEK650PF,PEEK 650G,High PV Wear Resistant PEEK WG101 ,Anti-Static Grade PEEK ESD101. which is a high performance engineering plastics, ultra-low viscosity resins, its MVR index is 6~12, the main processing methods are extrusion, molding, injection molding, and thermoforming, MVR index of 6~12, the main processing methods are extrusion, molding, injection molding, and thermoforming.

PEEK Forms

BW-Industry - Polyether Ether Ketone (PEEK) Tube

Polyetheretherketone (PEEK) tube is a lightweight tubing, high-temperature ,high press thermoplastic pla pipe. The PEEK tube produced using PEEK continuous extrusion moulding technology solves the technical problems of high limit in molding process products and easy internal shrinkage holes in injection molding process, while reducing losses and machining costs.

BW-Industry - Polyether Ether Ketone (PEEK) Film

PEEK film is made of PEEK particles by high-temperature melting, casting plastic film, the film is a performance & thermoforming film, with high temperature resistance, radiation resistance, resistance to hydrolysis, electrical insulation, barrier, and other properties; combustion products are almost non-toxic emissions; its balanced performance has made it become the market`s highest performance, the most widely used films. Its balanced properties make it one of the highest performing and most widely used films in the market.

BW-Industry - Polyether Ether Ketone (PEEK) Peek Sheet

Polyether Ether Ketone (PEEK) sheet is a new type of engineering plastic sheet extruded from PEEK. PEEK plate has good toughness, rigidity, fatigue resistance, heat resistance, corrosion resistance, wear resistance, its melting point is extremely high, can be up to 300 ? high temperature environment for a long time under stable operation, so it is widely used in aerospace, automotive, electronics, medical and other high-tech fields.

BW-Industry - Polyether Ether Ketone (PEEK) Monofilament & Multifilaments

Polyether ether ketone (PEEK) Monofilament & Multifilaments is made from polyether ether ketone resin by high temperature melt spinning. It has good physical properties, chemical stability, heat resistance, electrical insulation properties, but also has flame retardant and self-extinguishing properties. These excellent properties have been successfully used in aerospace, aviation, electronic information, petrochemical, automobile manufacturing and medical and health care and other fields. In addition, polyether ether ketone fiber can be recycled, raw material recycling rate of up to 90%, very friendly to the environment, but also reduces the cost of use.