Zhejiang Cxin Forging Technology Co., Ltd. products

Cxin - Hot Die Forging Technology

The friction press is the main hot die forging equipment from Cxin Forging Company. At present, the company has a die forging production line with 1600T hot die forging press, 1000T hot die forging press, 630T hot die forging press, and 400T hot die forging press as the main machines. The annual design capacity is 10,000 tons. The heating of the production line adopts an infrared temperature-controlled IGBT induction heating furnace.

Cxin - Cold Forging External Processing Technology

The fast hydraulic press is the main cold forging equipment of CXIN Forging Company. At present, the company has a cold forging production line with 630 tons of four-column rapid hydraulic press, 400 tons of cold forging rapid hydraulic press, and 300 tons of rapid cold extrusion press as the main machine. After 2022, it will increase by 800 tons and 1,000 tons of cold forging presses, with an annual design capacity of 4,000 tons.

Cxin - Warm Extrusion Technology and External Processing

Warm extrusion forming technology is a new technology of metal forming with fewer chips. It is different from cold and hot extrusion in that blank is heated before extrusion, but its heating temperature range above room temperature and below the complete recrystallization temperature. It is basically in the temperature range of incomplete cold deformation and incomplete thermal deformation of the metal. In the metal-plastic forming process and production, the warm extrusion forming technology will solve the problem of plastic forming of various metals and meet the filling problem of complex forging shapes.

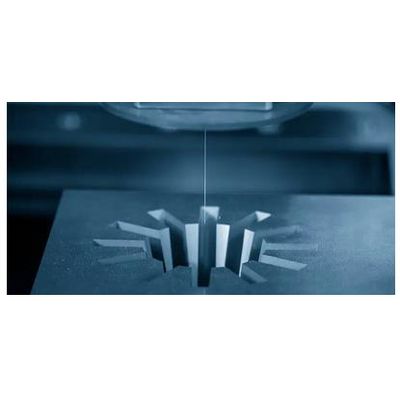

Cxin - Custom Mold - Forging Die

Forging die manufacturing is the first step to forging parts. Our engineers will design forging dies based on the drawings of new forgings. The design of the forging die depends on the processing steps, the nature of the workpiece material, the flow stress, and the working temperature, among other factors. Generally speaking, we need to accurately calculate the volume of the blank to avoid under-filling or overfilling. The choice of parting line (referring to the line where two molds intersect) is also very important. Sometimes for forged parts, there are multiple options to choose the parting line. Note that the parting line ensures the flow of materials is divided evenly. In other words, if there is no way to determine the parting line, forging is not feasible.