- Home

- Companies

- Zima Corporation

- Products

Zima Corporation products

Headworks

ProTechtor - Screenings Washer Compactor

The Kusters Water wash compactor is synonymous with hygienic and efficient handling of screenings. Screening disposal is a cost factor for every installation; wet screenings are heavy and increase disposal costs. The fecal matter in the water must also be delivered to the subsequent sewage purification process. The Kusters Water wash compactor reduces the weight and volume of the screenings while washing out more than 95% of fecal matter. Kusters Water wash compactors provide high performance combined with low operating costs to provide an excellent cost/performance ratio.

ProTechtor - Grit Washers

The Kusters Water grit washer consists of two basic items – a rotating perforated screening drum and a grit separator/washer unit, however, if the plant has fine screens (

ProTechtor - Vortex Grit Removal Systems

Kusters Water has been directly involved in the design, manufacture, supply, start up and testing of the XGT vortex grit removal technology since 1984. Based on experience with many installations, we have introduced a number of significant improvements to the system. These include the selfpriming grit pump and vortex grit classifier. The XGT vortex grit system is designed to efficiently remove both fecal and vegetable matter (corn, rice, beans, peas etc.) from the grit in the grit chamber resulting in cleaner grit with considerably lower organic content.

ProTechtor - Traveling Grit & Grease Bridges

The traveling bridge system utilizes a dual basin configuration consisting of an aerated grit chamber and grease collection chamber. The energy baffles contain the grit and promote settling in the grit basin floor. The grit is then collected via a submerged grit pump attached to the traveling bridge. The grit slurry is fed to a grit classifier, or grit washer, for further cleaning prior to discarding. The grease accumulates within the quiescent grease zone and is positively collected along the entire basin via a skimmer mechanism and pushed into a grease pit or removed via a screw conveyor. The system is fully automated and operates intermittently, run times can be easily adjusted by plant personnel.

ProTechtor - Static Screens

Kusters Water offers a complete line of factory built static screens. Every screen is designed to provide trouble free liquid separation. The open screen design accommodates peak hydraulic flows and the deep influent head box reduces influent turbulence while delivering an even flow over the weir crest. A pivoting flow control baffle plate is provided to enhance even flow distribution and promote faster fluid removal by directing the fluid into the screen.

ProTechtor - Circular Grit Collectors

Kusters Water Circular Detritus Tank, Grit Collectors are available in sizes ranging from 8 ft to 40 ft in diameter. The grit collectors utilize scraper arms that are designed to move the settled grit to the exterior of the basin where it is then discharged to a grit classifier or grit washer. Standard flow capacity ranges from 1.0 – 64 mgd in a single basin. Grit removal of >100 mesh grit is readily achieved by gravity settling.

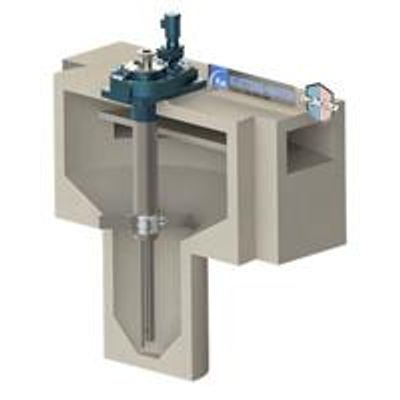

ProTechtor - Headworks Complete Plants

The Kusters Water HCP unit provides a total headworks solution for small and large facilities. The raw influent flow undergoes a series of pre-treatment processes including: Fine Screening, grit collection, grease collection and conveying.

ProTechtor - Perforated Plate Filter Screen

The Kusters Water Perforated Plate Filter Screen was developed to solve modern day screening problems which occur in wastewater pretreatment. The Kusters Water Perforated Plate Filter Screen eliminates operational disruptions caused by fibrous and other inorganic material. Depending on the perforated panel, the screened material is greater compared to a bar screen. The quality of the screened effluent is noticeably improved, which in turn improves performance and protects downstream equipment.

ProTechtor - Centerflow Band Screen

The Kusters Water ProTechtor Centerflow Band Screen, with its vertical orientation, is an excellent alternative to applications with limited footprint and headspace. Influent flow enters the screen in the middle of the screen frame, and is positively screened as the flow transitions from the inside and passes through the traveling perforated filter belt through the sides and bottom. Optimally spaced lifting tines are attached to filter panels to capture and elevate larger items to the internal discharge point. Screenings are washed off via spray headers and/or a combined motorized brush assembly, and are discharged to an internal flume or screenings washer compactor, which transports the screenings outside of the screen frame. The quality of the screened effluent is drastically improved which in turn improves performance and better protects downstream equipment.

Terminodour - Ionized Odor Control

Whereas other systems extract and treat odors, the Terminodour system is unique in that it oxidizes the odor at the point of the source. The ionized air is distributed into the building where it reacts and oxidizes odors while maintaining a healthy working environment for operators and reducing corrosion. Terminodour uses no water, chemical or media which minimizes capital and operational costs in dealing with spent media or consumables. There are more than 150 operational Terminodour plants worldwide.