Zwirner Equipment Company services

Industrial Equipment Reconditioning and Remanufacturing Services

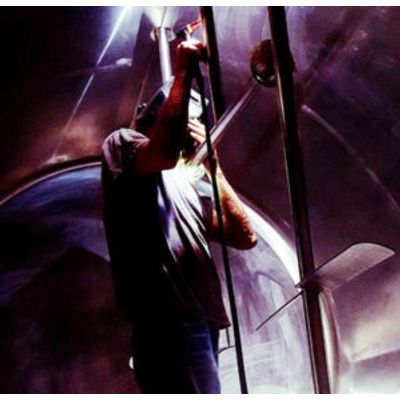

Zwirner Equipment Company, with over three decades of experience, is a leader in reconditioning and remanufacturing used stainless steel processing equipment. Their thorough reconditioning process ensures that all machinery is restored to full functionality, efficiency, and compliance with original manufacturing specifications. Reconditioning involves a comprehensive overhaul using new replacement parts, presenting an economical alternative to purchasing new industrial equipment. Their skilled fabricators and machinists tailor the reconditioning process to the specific needs of the equipment and customer modifications. As industrial equipment prices surge, especially for storage tanks and dairy equipment, opting for reconditioned equipment from Zwirner Equipment ensures high quality and reliability. Additionally, their equipment transportation services offer safe and cost-effective delivery. With a focus on quality and customer service, Zwirner Equipment stands out as an excellent choice for businesses seeking reconditioned equipment solutions.

Custom Stainless Steel Fabrication Service for Industrial Applications

Zwirner Equipment Company specializes in custom stainless steel fabrication, catering to diverse industrial applications. With over 30 years of experience, the company provides remanufacturing services and custom-fabricated parts tailored to the unique specifications of process plants. Zwirner Equipment ensures that plants operate efficiently by supplying parts that are precisely designed and built for individual needs. Beyond fabrication, the company assists with the installation and technical maintenance of equipment, tackling challenges that arise in the field. Their services support Pasteurization and CIP systems, ensuring compliance with CIP and HTST audit requirements. Zwirner also offers reprogramming services, maintaining industrial equipment to ensure peak performance throughout its lifecycle. Installation services backed by a robust support team aid in resolving technical difficulties and maintaining operational continuity. The company invites inquiries for custom fabrication solutions needed to optimize plant performance.