H.E.L GROUP

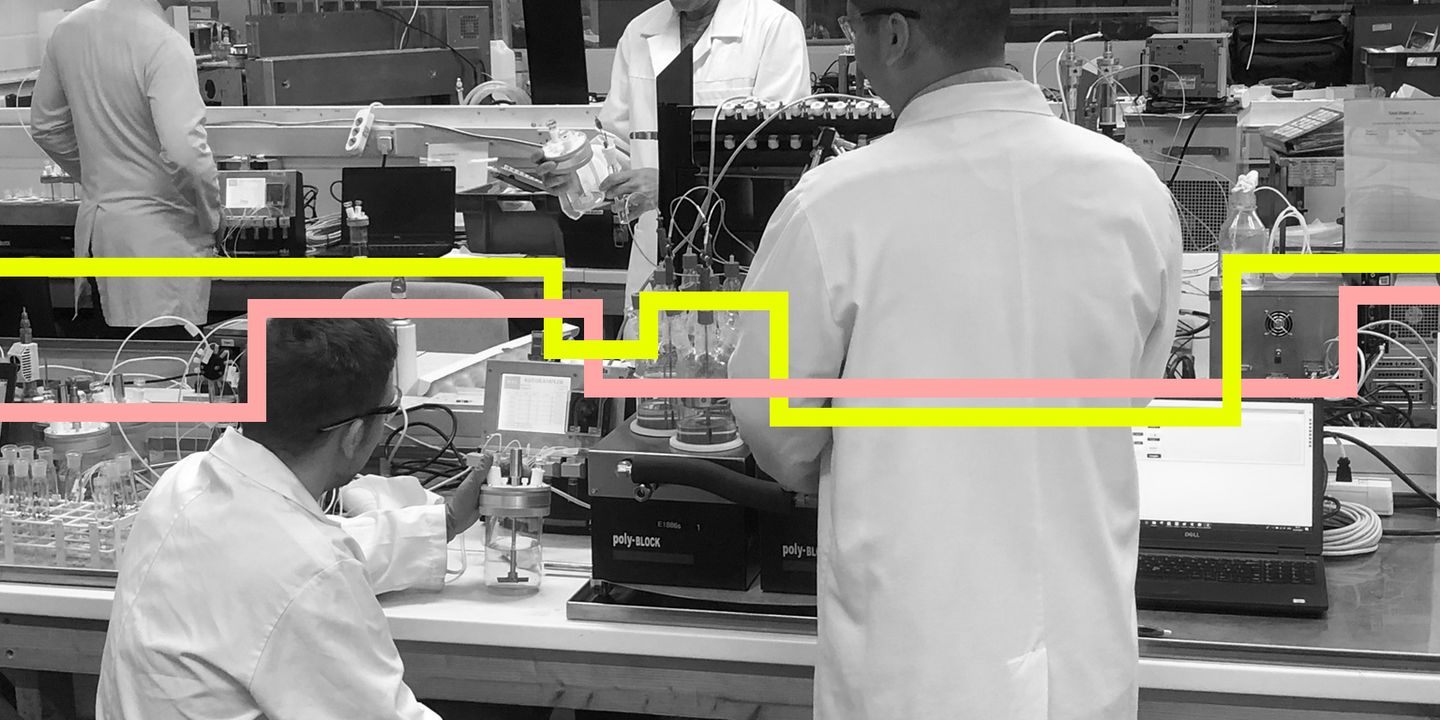

Flexible and Compact Multi-Reactor System-PolyBLOCK

...Online, Real-time, Affordable... WWW.HELGROUP.COM marketing@helgroup.com +44 (0)20 8736 0640 Reaction Calorimetry For Process Development and Safety Want to increase use by R&D chemists? Want to improve methodology for specialists? Reaction Calorimetry enables ... Reaction tracking ? Determine end-of-reaction on-line ? Track on-line, changes in reaction rate or mechanism ? Directly compare different routes or process changes ? Determine if reaction is feed or kinetic controlled Process Safety ? Cooling duty needed ? Potential temperature/pressure rise Calorimetry is now accessible to development chemists on ANY stirred reactor without special features or adaptations. Calorimetry theory has been imbedded into HEL’s proprietary reactor control software to allow direct and on-line display of heat release as reaction proceeds. In order to increase use by R&D chemists, simplifications based on sound data and over 20 years experience have been incorporated while for those looking for accurate data, full and complete theory has been re-tained but with time-saving calculations still done on-line and in real-time. www.helgroup.com ... Flexible, Adaptable, Modular .... Considerable development effort has been expended in develop-ing methodology that will encourage large numbers of chemists to embrace calorimetry as additional insight into their process with-out ANY extra hardware or additional experimental time being necessary. The key features are the following: Basis ? No knowledge of methodology or theory required ? May be used with minimal or even zero user input ? Data displayed in real-time as reaction is performed ? No extra experimental time required ? No off-line analysis/calculations needed Hardware ? Existing or new, jacketed reactors ? Special software interface for chemists averse to computer control ? Software implementation on a PC or special microNOTE touch-screen monitor ? Compact design to suit already crowded fume hoods Special Features ? “HF” meter supplied to allow con-firmation of data ? On-site training by experienced chemists ? Software for complete automa-tion of reactor ? Ability to expand system HEL’s proprietry SIMULAR reaction calorimeter is now supplied with this new on-line methodology in place, allowing high level calorimetry analysis but with-out the need for time consuming experimentation or specialist off-line analy-sis. Key features are: ? Sound calorimetry theory and well researched methodology to provide accurate results ? Custom electronics and reactor hardware ? On-line calculation of heat release, in real time ? Choice of heat flow and power compensation calorimetry Key benefits compared with conventional reactor calorimeters include: ? No time lost for UA calibrations (with power compensation) ? No off-line calculations (even for heat flow) ? All calculations are automated and on-line, real-time ? Fast control and accurate results HEL’s simplified heat flow methodology can also be implemented on multiple reactor systems, giving on-line and real time results in parallel. This has al-ready been implemented on HEL’s PolyBLOCK and AutoMATE platforms and typical results are shown. UK Corporate Headquarters HEL Ltd. 9-10 Capital Business Park, Manor Way, Borehamwood. Hertfordshire. WD6 1GW, UK Tel: (0) 2087 36 0640 Fax: (0) 2087 36 0641 Email: marketing@helgroup.com USA Tel: (+16) 09 912 1551 Email: marketing@hel-inc.com Italy Tel: +39 0261 868 225 Email: helitalia@helgroup.com India Tel: +91 222 586 1324 Email: info@helindia.com Calorimetry for R&D chemists Calorimetry for parallel applications On-line/ Off-line Calorimetry Comparison (Acetic anhydride dosed into water at 40°C) Reaction Energy (kJ) Dose Energy (kJ) Molar Heat (kJ/mol) On-line before final baseline correction 62.2 5.5 52.9 On-line after final baseline correction 71.3 5.5 59.9 Off-line calculation 71.3 5.5 59.9 Calorimetry for “serious” or specialist applications Turn simple existing reactors into automated systems at minimum cost—compact control unit with touch screen interface “HF” Meter www.helgroup.com

Most popular related searches