KATE PMO AG

KA-TE Filler Robot Brochure

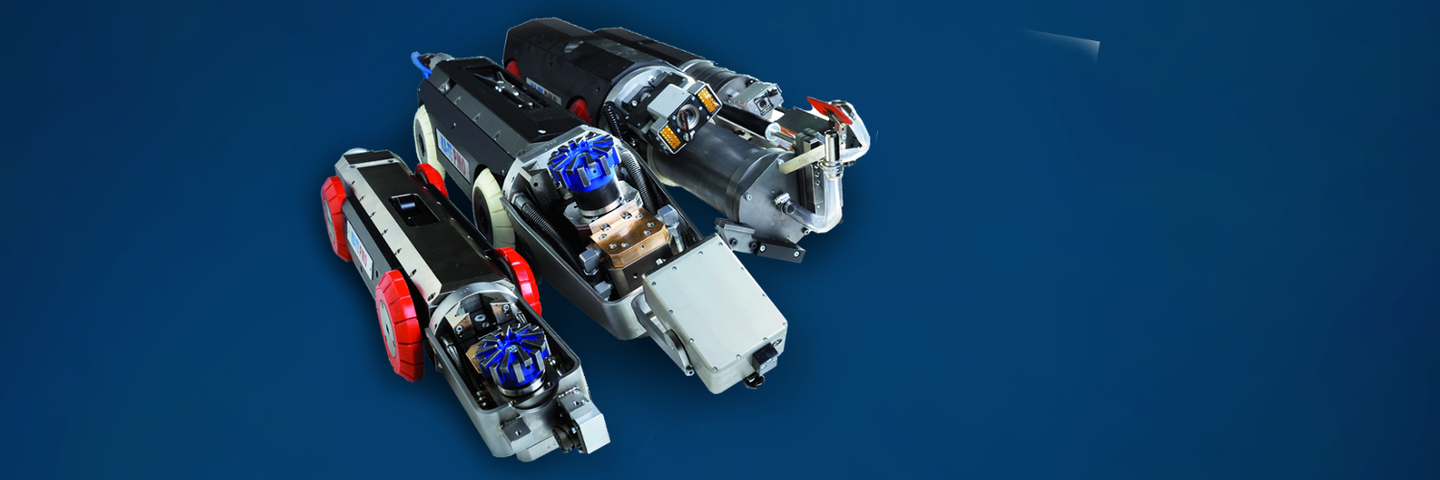

NeWKA-TE COMPACT – now available as mobile systemKA-TE FILLER ROBOT200/300 AND 250/600DURABLE REPAIRSWITH EPOXY RESINKA-TE PMO AGSteineggstrasse 32CH-8852 Altendorf /SuisseTel.: +41-55-4 15 58 58Fax: +41-55-4 15 58 59info@ka-te.chwww.ka-te.ch• Pipe diameter: 178-300 mm• Length with cartridge: 1030 mm• Cartridge capacity: 1.8 Litre• Rotation of filler head: 670°• Extension of the slides: 80 mm• Weight: 34 kg• Pipe diameter: 250-800 mm• Length with cartridge: 980 mm• Cartridge capacity: 2.75 Litre• Rotation of filler head: 560°• Extension of the slides: 88 mm• Weight: 54 kgTechnical specifications• Wheels and wheel hubs for DN 200-300• Filler tools for longitudinal and axialcracks• Adapters for camera• Wheels and wheel hubs for DN 250-400• Undercarriages forDN 450-600 and DN 700-800• Egg shape tool forDN 300/450 - DN 600/900• Filler tools for longitudinal and axialcracks• Adapters for cameraAccessoriesKA-TE Mini Filler Robot DN 200/300KA-TE Filler RobotDN 250/600The KA-TE Filler Robots are delivered ready for use in different carriage variations. With the KA-TE COMPACT, we offer a mobile,portable system, which can also be developed into a multi-functional system.Training for use of our robot systems is carried out at the plant or on site by experienced members of our service staff.Proven for more than 15 yearsMore than 500,000 repairs have been carried out worldwideGIVE US A CALLTel. +41-55-4 15 58 58• Epoxonic EX 1013, • Epoxonic EX 1355, • Epoxonic EX 1824-rapid, • PCI Concresive 1850• SIKA RoboTec 61• ROBO-SIL-rapidEpoxy resin for repairs with high final strengthModified (reduced E-module) epoxy resin primarilyfor connections.More fluid epoxy resin for shield placing module.Proven all-round resin for filling work and forthe shield placing module.Proven all-round resin for filling work and forthe shield placing module, special packagingfor use with static mixers.Quick-curing silicate resins – exclusively forwork with shield placing module. (Specificconditions of use and operating conditions)The following high-quality epoxy resins have proven themselves through the KA-TE procedure for years and have been qualified by KA-TE:All Epoxonic resinshave DIBt approvalCall us, we will find theright epoxy resin for you.KA-TE FILLER ROBOTwww.ka-te.chKA-TE Mini Filler Robot DN 200/300For pipe diameters of 200-300 millimetresKA-TE Filler Robot DN 250/600For pipe diameters of 250-800 millimetresTo repair damaged spots.Clean and durable results.With longitudinal or radial fillerattachment and refillable cartridge.WHEN THE RESULTS MATTERThe KA-TE filler robot is supplied with diverse spatul a tools allowinghigh flexibilit y and precision during filler work.The various tools make it possible to repair complex damages, such ascircumferential, longitudinal or even multiple cracks.KA-TE FILLER ROBOTDN 200/300 AND DN 250/600The robust and flexible filler robotsKA-TE DN 200/300 and DN 250/600are used to make durable repairs ofdamaged spots and connections in piperanging from 200 to 800 millimetresin diameter. Since the introduction ofthis innovative procedure, more than500,000 repairs have been carried outworldwide. Even the first repairs arestill providing a robust and functionalsolution today – after 15 years.Functional and durable results are obtainedby the procedures of the KA-TE filler robots.Epoxy resin is pressed into the pre-groundarea by the robot from a refillable cartridge.A durable, frictionless connection/repairwork is formed.Depending on the type and extent of thedamage, a longitudinal or radial filler toolis employed. With its infinitely variableelectrical propulsion and rotary drive, thefiller robot can be guided with millimetreprecision. Damaged fittings and connectionscan be restored with the KA-TE shieldinjection system.Due to the compact design, even difficult-to-reach places become accessible. Themachines are made from high-qualitymaterials and extremely resilient. Theirdesign also makes them easy to service.Test winners in IKT product tests 2004 & 2009Twice certified by the renowned, impartialinstitute IKT: The KA–TE repair techniqueis currently the top proven robotic techniqueon the market. The KA-TE method wasawarded a rating of 1.6 in the IKT producttest "Repair Methods for Main Sewers"(2009); the best result in the group"Injection and Filling/Grouting Methods".Already in 2004, it was the method withthe best test result: 1.9 for standard damageand test winner in the IKT product test"Repair Methods for Lateral Connections".The long-term durability of the KA-TEtechnique in relation to high-pressurecleaning was confirmed in 2010 by anindependent body, the IRO – Instituts fürRohrleitungsbau Oldenburg ("Institute forPipeline Construction"), by a series of testsfollowing DIN 19523 (August2008 edition). It has beenproven that filling usingthe KA-TE filler robotsfulfils the criteria of anew pipe in practicaland materials tests.