KATE PMO AG

KA-TE Image Brochure

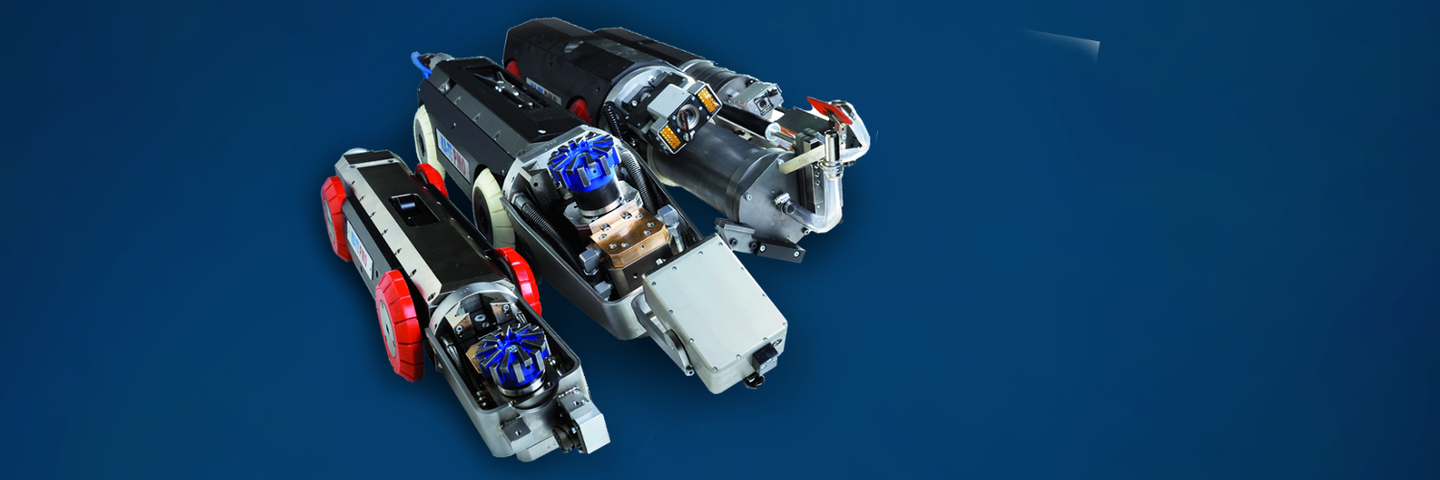

SUCCESSFUL SEWERReHAbIlITATION THrOUGHQUALITY AND PRECISIONHIGH-TECHSEWER ROBOTSFROM KA-TEW H e n T H ER ES U LT SM at T E Rwww.ka-te.chIn the 1970s, KA-TE was the first companyin the world to manufacture remotely-controlled robots for sewer rehabilitation.Our main guiding principle from back then,is still our main guiding principle today:We want to provide end users with mostrobust, high-performance machines of thehighest quality that will fulfil their dailytasks reliably for many years even in theharsh conditions of the day-to-day work insewer rehabilitation. Every robot that weproduce is built from decades of hands-onexperience and combines cutting-edgetechnology with Swiss precision. This is whyKA-TE grinding and filler robots arethe first choicefor sewer reha-bilitation teamsi n s o m a n ycountries. At KA-TE, quality takes priority. This appliesfrom product design, manufacture, todelivery as well as for service. We believein the highest quality materials, latesttechnology, precision and the highest levelsof technical expertise.Our aim is to deliver robots that yieldflawless results and support the succesfulgrowth of our customers business.Our robots are built to last and extremelyreliable. Annual service costs have shownto be the lowest in the market.For this reason, every day we challengeourselves to build machines that meet thehighest requirements.www.ka-te.chTHE KA-TE FORMULA FOR SUCCESS:CUTTING-EDGE TECHNOLOGY AND SWISS PRECISIONIn 1976, the company was foundedin Zurich.The world's first manufacturer ofremotely-controlled robots for sewerrehabilitation.Robust, high-performance robots builtwith Swiss precision for the tough “day-to-day” work of sewer rehabilitation.THE COMPANYPRECISE MANUFACTURE DuE TODECADES OF EXPERIENCEWhat started it all off was the ideaof a robust robot system that enablesits users to implement the most cost-effective sewer rehabilitation solutions.www.ka-te.chThe KA-TE principle still applies today.The original “tried and testet” designremains the same.Many of the first-generation devicesare still in use today.The oldest robot system that is in dailyoperation today was built in 1989.The KA-TE principle still applies todayIf it is possible to execute complex flightmanoeuvres via remote control, it must alsobe possible to repair damaged sewers usingremotely-controlled robots. This idea for arehabilitation robot came to KA-TE founderErich Himmler in the 1970s through hishobby, building model aeroplanes. He wasalready familiar with the problems relatingto the rehabilitation of non-man-entry sewersduring his work at the Zurich Public WorksDepartment. Robots offered new perspectivesfor a more convenient, trenchless rehabili-tation: more environmentally friendly, quietand clean, with less restrictions for trafficand local residents than the method ofopen cut trenching.Since the founder of KA-TE and his develop-ment team were well aware of the highrequirements necessary for deployingmachines in sewers, they knew from thebeginning what the critical features for agood robot system were: reliability, robust-ness and the ability to carry out complexrepair work. These are the basic principlesthat still apply to the manufacture of KA –TErobots today.1979Development of thesewer robot begins1984Sewer rehabilitation usinggrinding and fillerrobots begins in Zürich1980First sewer robotdeployed1987Sale of the first KA-TEsystem in Switzerland1988The first three systems aredelivered to GermanyBUILD TO LAST (ALMOST) AN ETERNITYThe original tried and tested design remains the sameA fundamental decision made during theconstruction of the first prototypes con-tinues to define KA-TE systems today: thehydraulic drive.It guarantees long-term performance,enables the robot to be used in high orlow temperatures, with an abundance oftorque and it is significantly quieter thanpneumatic systems.KA-TE goes beyond when others have reached there limitsWith technical precision and a focus onpractical use, the fields of application forthe KA-TE systems have been continuouslyrefined and developed over the years.Today, users from all over the world provedaily that consistent commitment to qualitypays off in practice: Where other systemsreach their limits, you can almost alwaysfind a solution with KA-TE robots.Many of the first-generation devices are still in use todayBuilt to last (almost) an eternity: Until now,around 300 KA-TE systems have beendelivered worldwide – and most of themare still in use. The robots are designed tobe extremely robust and, if necessary, easyto repair. They excel through a long servicelife, have a very good wear resistance andare virtually indestructible: Some KA-TEusers report having used their grindingrobots continuously non-stop for more thanseven days.The basic principle of maximum cost-effective-ness for the user applies to maintenanceas well: Whoever invests in a KA-TE systemcan be certain that the supply of spareparts is guaranteed, even for older systems.It's not surprising then, that many firstgeneration KA–TE robots are still performingtoday as reliably as they did 20 years ago– with the precision of a Swiss watch.1994Shield placing mechanismis introduced2004Test winners of the IKT Producttest "Repair Methodsfor Lateral Connections"2009Test winners of the IKT Producttest "Repair Methodsfor Main Sewers"www.ka-te.chKA-TE grinding robotKA-TE filler robotBest method in the IKT Product testThe high quality of the method was con-firmed by the IKT Product tests "RepairMethods for Main Sewers" (2009) and"Repair Methods for Lateral Connections"(2004). In both tests, the KA-TE systememerged as the test winner.KA-TE Mini grinding robot DN 150/300and KA-TE grinding robot DN 250/600In sewer pipes up to DN 800 these high-tech,hydraulically powered, high-performancerobots grind away deposits, root penetrations,protruding laterals and other obstructions.They are also used to prepare sewers forrelining and re-opening lateral connectionsafter lining.Various tools for grinding, cutting andsmoothing allow for versatile use. Evencompletely blocked pipes can be re-openedquickly using the robots in frontal grindermode.KA-TE ROBOT SYSTEMS: PRECISE, EVEN IN THE HARSHEST CONDITIONSKA-TE Filler robots DN 200/300 and DN 250/600The KA-TE filler robots DN 200/300 andDN 250/600 are used to precisely restorepoints of damage and lateral connectionsin circular sewers ranging from 200 to 800millimetres in diameter. This process usesepoxy mortar, which is delivered from arefillable cartridge by compressed air andapplied with a spatula shaped tool. De-pending on the type of damage, either alongitudinal or a radial spatula tool canbe used.With its infinitely variable propulsion androtary drive, the filler robot can be guidedwith millimetre precision.Damaged or poor lateral connections canbe filled and restored with the KA-TE shieldplacing mechanism.KA-TE Filler Robot DN 250/600For pipe diameters of 250-800 millimetresKA-TE mini Grinding Robot DN 150/300For pipe diameters of 150-300 millimetresKA-TE Grinding Robot DN 250/600For pipe diameters of 250-800 millimetresKA-TE mini Filler Robot DN 200/300For pipe diameters of 200-300 millimetresPRODUCTS / FIELDS OF APPLICATIONPROVEN QUALITY: KA-TE PASSED THE IKTPRODUCT TEST WITH FLYING COLOURSKA-TE Shield Placing Module DN 250/600For pipe diameters of 250-800 millimetresKA-TE Shield Placing Module DN 200/300For pipe diameters of 200-300 millimetresKA-TE Shield Injection SystemWinner of the IKT Product test in 2004With its Shield Injection System, KA-TE offersa patented method for a clean and durablerehabilitation of lateral connections.The Shield Injection System is attached tothe filler robot allowing a plastic shield tobe positioned at the point of the lateralconnection. A balloon is then inserted intothe lateral through an opening in the plasticshield and inflated to tightly fit the connection.The plastic shield is then expanded overthe balloon to form a secure, tight formwork.The resin is pressed into the cavity aroundthe balloon through two injection holes inthe plastic shield. After hardening of theresin, the shield and balloon are removed,and no further work is required.TrIed ANd TeSTed MeTHOd fOr PerfeCTreNOVATION Of LATerAL CONNeCTIONSEven large holes, missing sections of thesewer wall and complicated ruptures canbe filled with resin – a quick and easy-touse, precise, trenchless method of repairand shown to have no effect even ondrinking water.The key benefit with this method of repairis the quality and durability of the pointwhich has been newly renovated. The resinis applied to lay flush with the pipe wall.This means that – in contrast with othermethods – there is no risk of the repairedpoint sustaining damage again even underhigh-pressure cleaning afterwards.PRODUCTS / FIELDS OF APPLICATIONHIGH-PERFORMANCE, HIGH-TECH ROBOTSWITH VARIOUS ACCESSORIESKA-TE Customer serviceThe KA-TE product range is complementedby all the necessary accessories. Theseinclude both high-quality, robust tiltingcameras and egg shape carriages from DN300/450 to DN 600/900 for our robotsystems, as well as purposely designed, fullyequipped vehicles, containers and trailers.Genuine customer serviceSuccessfully completed rehabilitation pro-jects are the best reference for our products.This is why the KA-TE quality philosophyincludes a full service portfolio.Comprehensive warranty services and pro-fessional support is provided by trainedtechnicians. We offer our customers a tele-phone helpline where competent techniciansand operators are ready to help you withany operational or technical problem thatyou might encounter.KA-TE products are designed to facilitatethe quick and efficient execution of projectswith high-quality results. A quick deliveryof replacement parts ensures that expensivedowntime is kept to a minimum. In orderto be able to process all your orders in goodtime, we keep our stores well stocked andco-operate with express and overnightcourier services for the best possible delivery.OUr GOAL: THE SUCCeSSfUl COMpleTIONOF YOUr reHAbIlITATION prOJeCTEQUIPMENT UND SERVICEKA-TE Robot systems can be delivered in purposely designed,fully equipped rehabilitation vehicles, containers or trailers.The KA-TE product range is complemented by a comprehensiveselection of accessories . These include high-qualit y t ilt ingcameras and egg shape carriages up to DN 600/900.IF YOU HAVE ANYQUESTIONS,PLEASE GIVE US A CALLKA-TE PMO AGSteineggstrasse 32CH-8852 Altendorf /SchweizTel.: +41-55-4 15 58 58Fax: +41-55-4 15 58 59info@ka-te.chwww.ka-te.chSprinter 519 5,0 tBox truck 10,0 tSprinter 316 3,5 twww.ka-te.ch

Most popular related searches