KATE PMO AG

- Home

- Companies & Suppliers

- KATE PMO AG

- Downloads

- KA-TE- Shield Injection System Brochure

KA-TE- Shield Injection System Brochure

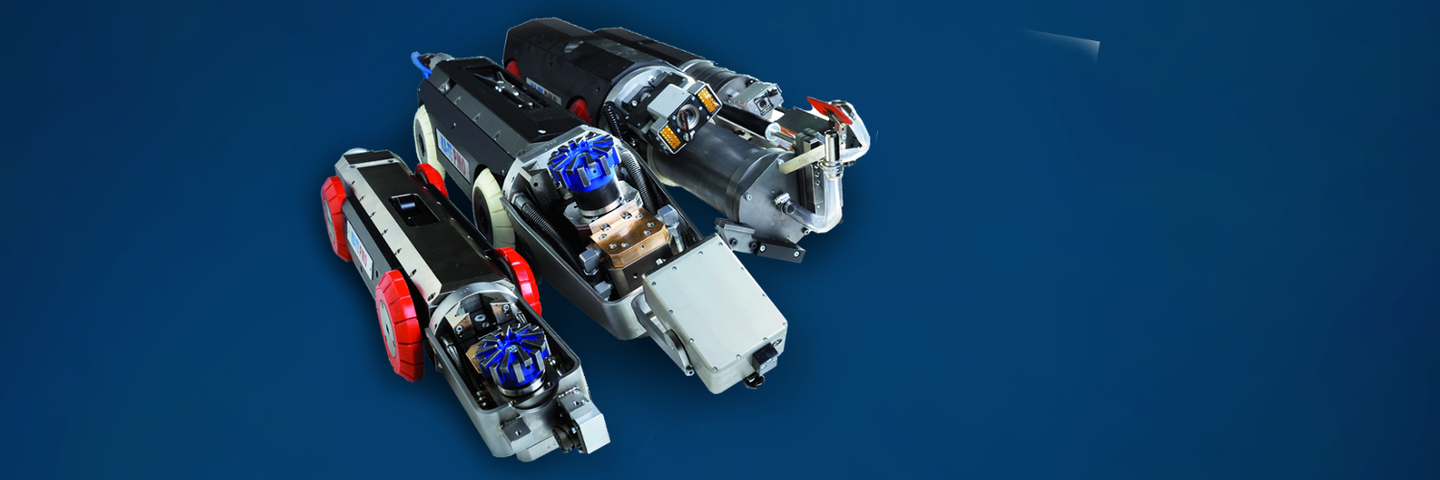

NewKA-TE COMPACT – nowavailable as a mobile systemKA-TE SHIeLd INJeCTION SYSTeM200/300 AND 250/600REPAIR METHOD FOR THEREHAbILITATION OF LATErALS• Pipe diameter: 200-300 mm• Length: 610 mm• Length with robot: 1160 mm• Drive of the shield placing motors: 24V AC• Weight: 11 kg• Pipe diameter: 250-800 mm• Length: 560 mm• Length with robot: 1170 mm• Drive of the shield placing motors: 24V AC• Weight: 8 kgTechnical specifications• Shields with diameter100 mm/120 mm/150 mm• Shields without hole• Tie-down straps for DN 200-300• Socket shields for DN 200-300• Shields with hole diameter100 mm/120 mm/150 mm/180 mm• Shields without hole• Tie-down straps for DN 250-800• Socket shields for DN 250-800AccessoriesKA-TE shield placing module200/300KA-TE shield placing module250/600The KA-TE shield injection system is delivered ready for use in different carriage variations. With the KA-TE COMPACT, we offera mobile, portable system, which can also be developed into a multi-functional system.Training for use of our robot systems is carried out at the plant or on site by experienced members of our service staff.Proven for more than 15 yearsMore than 300,000 renovated lateralsKA-TE PMO AGSteineggstrasse 32CH-8852 Altendorf /SuisseTel.: +41-55-4 15 58 58Fax: +41-55-4 15 58 59info@ka-te.chwww.ka-te.chGIVE US A CALLTel. +41-55-4 15 58 58• Epoxonic EX 1013, • Epoxonic EX 1355, • Epoxonic EX 1824-rapid, • PCI Concresive 1850• SIKA RoboTec 61• ROBO-SIL-rapidEpoxy resin for repairs with high final strengthModified (reduced E-module) epoxy resin primarilyfor connections.More fluid epoxy resin for shield placing module.Proven all-round resin for filling work and forthe shield placing module.Proven all-round resin for filling work and forthe shield placing module, special packagingfor use with static mixers.Quick-curing silicate resins – exclusively forwork with shield placing module. (Specificconditions of use and operating conditions)The following high-quality epoxy resins have proven themselves through the KA-TE procedure for years and have been qualified by KA-TE:All Epoxonic resinshave DIBt approvalCall us, we will find theright epoxy resin for you.KA-TE shield injection systemKA-TE SHIELD INJECTION SYSTEMwww.ka-te.chWHEN THE RESULTS MATTERThe patented KA-TE shield injection system allows not only for technically perfect rehabilitationof laterals, but also the repairs of extreme damage. This procedure can be used in circularprofiles dn200 up to dn800 and egg-shaped profiles up to 600/900.The specific shaping of the shield ensures a smooth transition between the repair and thewall of the main sewer pipe. As a result, hydraulic performance of the sewer system isimproved. This also guarantees reliability and durability even with frequent and intensivesewer cleaning. This has been proven by cleaning tests.KA-TE shield placing module 250/600For pipe diameters of 250-800 millimetresKA-TE shield placing module 200/300For pipe diameters of 200-300 millimetresLateral, defective and rehabilitatedTRIED AND TESTED METHOD FOR ApErFECT rEHABILITATION OF LATErALSThe detachable shield was the decisive steptowards a significantly higher level ofefficiency and improved quality. Due tothis independence, the resin can cure andform a bond with the component withoutinterference. This means: Better quality andlonger-lasting repairs.Test winners in IKT product test 2004KA-TE systems for the repair of sewers havebeen proven to be among the best methodsoffered on the market.In the IKT product test "Repair Methodsfor Lateral Connections" in 2004 held bythe renowned, independent IKT institute,Gelsenkirchen, the KA-TE techniqueemerged as the winner.The long-term durability of the KA-TE methodin relation with high pressure cleaning wasconfirmed in tests following DIN 19523(version of August 2008) that were conductedby the independent, Oldenburg-based IRO“Institute for Pipeline Construction” in early2010.Reliable repairs with the KA-TE shieldinjection systemThe KA-TE shield injection system is apatented method that can be used, amongother things, for a durable and robust repairof laterals. This method was, and remainsto this day, one of the key innovations inthe field for repair methods using robotsystems.Since its introduction, this innovativemethod has been employed worldwide inmore than 300,000 repairs of lateralconnections. Even the first repairs are stillproviding robust and functional connectionstoday – after 15 years. This means thata considerably longer service life can beexpected than the 5 years that are stillprojected today.The KA-TE shield placing module positionsits attached plastic shield over the openingof the lateral. Then a balloon is insertedthrough an opening in the shield to serveas a mould for the missing pipe. Resin ispressed into the cavity around the balloonthrough the two holes by an injection tool.The shield can be detached from the robotand stay in place until the resin has cured.

Most popular related searches