Trislot N.V.

- Home

- Companies & Suppliers

- Trislot N.V.

- Downloads

- Off-onshore brochure (in english)

Off-onshore brochure (in english)

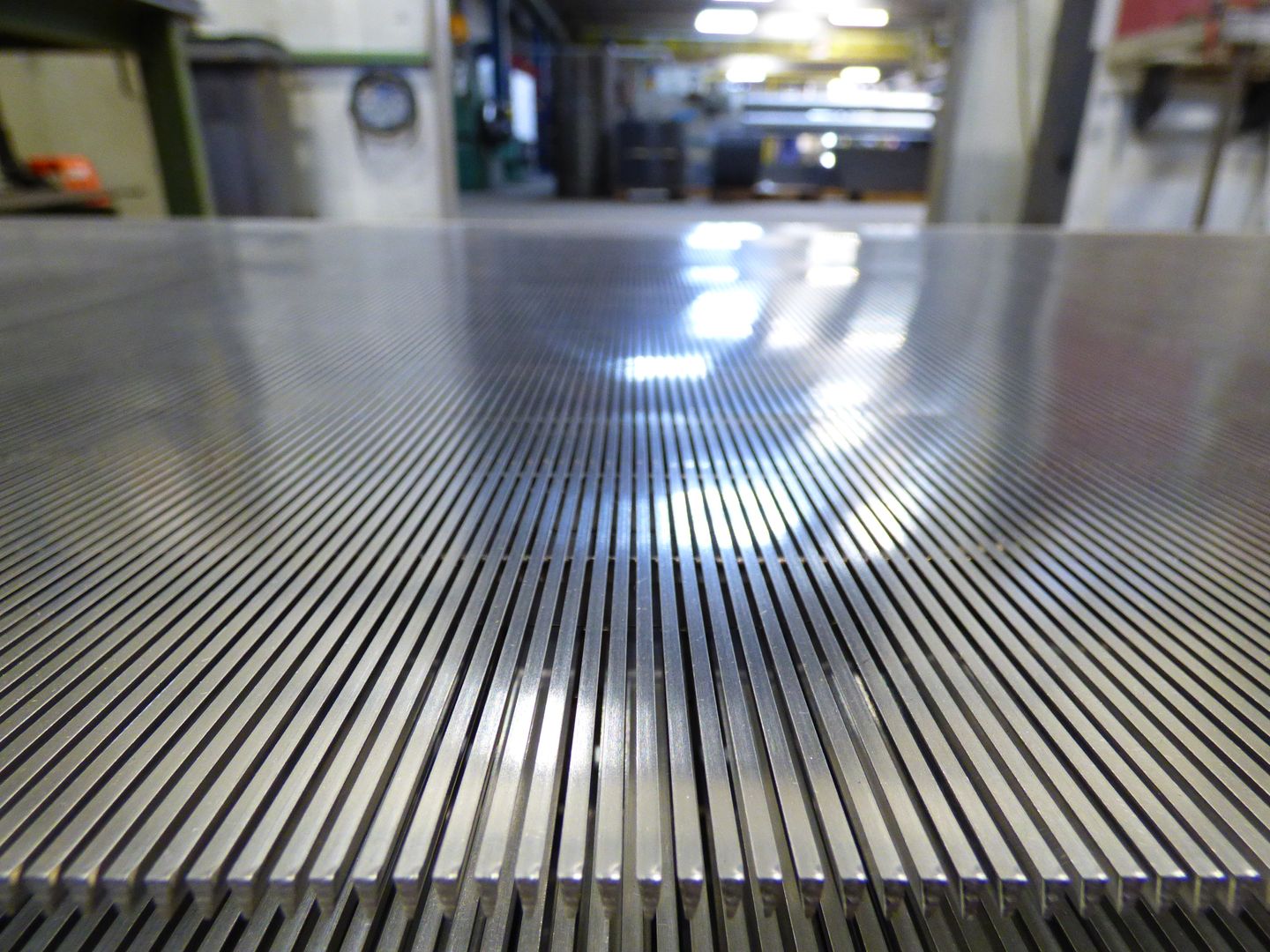

1 On- and Offshore Filtration Applications 2Different Applications1. Elements for Coarse strainer Typical applicationRemoval of solid contaminates from injection seawater, mostly used in a self cleaning system (scrapers, backwash, suction nozzles,…). These elements can either be slot tubes or cylinders. Common product specifications Material : Super duplex UNS 32550 / UNS 32750-60 (NORSOK M650 certified material) / SMO 254 / Titanium GR II / Monel 400 / Hastelloy / 316L /… Flow in to out Slot opening : 40µm – 5mm Diameters: 150mm and up Cleaning by brush, scraper, suction scanners, Bernoulli effect, backwash or disc cleaning Injection waterProduced waterCoarse StrainerBackwash systemMultimedia filter systemNutshell FiltersBackwash systemWhy choose Trislot®?Trislot is the world leader in wedge wire filter ele-ments for on- and offshore filtration applications. You can rely on our engineering team to assist you in the product specification. In the past Trislot has proven itself as a reliable partner to companies active in the on- and offshore market. Slottube flow in to out for cleaning by backwashReverse rolled slottube for cleaning by brush or suction scannersWedge wire advantages Needless to say that the maintenance cost and risk of defects need to be min-imalized on offshore appli-cations. Wedge wire holds advantages that have a larger return on invest-ment than any other filter medium: Strong mechanical construction Non-clogging surface No maintenance or replacement costs3 2. Slot tubes for Automatic Backwash FiltersTypical applicationContinuous removal of solid contaminates from injection/produced seawater.Common product specifications Materials : Super duplex UNS 32550 / UNS 32750-60 (NORSOK M650 certified material) / SMO 254 / Titanium GR II / Monel 400 / Hastelloy / 316L /… Slot tubes Flow in to out. Slot opening : 40µm - 500µm Diameters: 25mm and upWedge wire advantages In this application high flow rates are common. Because of the continuous slot, wedge wire gives a high open area. Therefore the total volume of the installation is less than with other media. Small foot-print and light weight is of im-portance in offshore applica-tions. Other advantages are: Strong mechanical construction Non-clogging surface No maintenance or replacement costs Perfect round slot tubeFilter cycleDuring the filter cycle, the solids are deposited on the smooth surface. This cake acts as an extra filter for finer particles. The fines that slip through do not get stuck in the conical slots.Backwash cycleBy reversing the flow, the cake and dirt are removed from the filter surfaceFilteringBackwashing 43. Wedge wire in Multimedia Filter: Distributor-Collector, Header & LateralsTypical applicationsTreatment and filtration of injection/produced seawater through multi-media vessel. Common Product Specification Materials: Super Duplex UNS32550 / UNS32750-60 (NORSOK M650 certified material) - Stainless Steel 316L Flow out to in slot opening :50µ - 500µ Profile width : 1 – 1.5 mm diameter slot tubes: 25 mm and upAdvantages collector system with wedge wire lateralsCompared to other solutions this collector system guaran-tees that there are no dead zones in collecting the fluid, which means a faster filtra-tion. Other important advan-tages are : Superb backwash ability and non-clogging Custom-made and fit for purpose Excellent flow distribution and media retention Strong construction Long service life Low maintenance costs5 4. Nutshell filter bottomsTypical applicationsRemoving/retaining of suspended solids and hydrocarbons, oily residues,etc in produced seawater through nutshell (Wallnut/Pecan) -media filter layer. Allowing reinjection into source (Water flooding).Common Product Specification Materials : Stainless Steel 304 / 316L (other materi-als are available e.a. Super Duplex) slot opening : 250 - 500µ Profile widths : 0.75 – 1 – 1.5 mm Product advantagesBecause of the continuous slot wedge wire has more open area than other filter media. Thereby the cleaning cycle becomes shorter. The wedge wire filter bottom is made of cold drawn wire that gives more mechanical sta-bility than for example milled plate. If necessary at all we can reinforce the wedge wire bottom without reducing the open area. Other advantages equally important are : Superb backwash ability and non-clogging Custom-made and fit for purpose Excellent flow distribution and media retention Rigidity Long service life Low maintenance costs 6Trislot® Quality Assurance ISO 9001 Certified NORSOK M630 production process Trislot® focuses on Total Quality Management 50 years of experienceTrislot® dedicated Sales teamReferencesRecently Trislot® has successfully manufactured some nutshell filter bottoms/collector systems to high profile customers enabling them to meet the very strict North Sea requirements.More than 20 years we have been producing filter elements for injection water and produced water the world leading players in the oil & gas. Now recently acquired jobs: multiple injection/produced water projects in Santos Basin – Brazil Full NORSOK certified elements for North Sea (Spare) parts for projects based in Australia, Angola, Qatar, Gulf of Mexico, Caspian Sea, Myanmar, Vietnam, …Roterijstraat 134 - B-8970 Waregem - Belgium - T +32 56 62 72 22 - F +32 56 62 72 62 - info@trislot.bewww.trislot.beFrom left to right : Mike Verduyn, Marie Cheyns, Yannic Lievrouw, Glenn Vercruyce, Sandra Van Slambrouck, Yves Struyve, Nurit Galling, Geert Follet

Most popular related searches