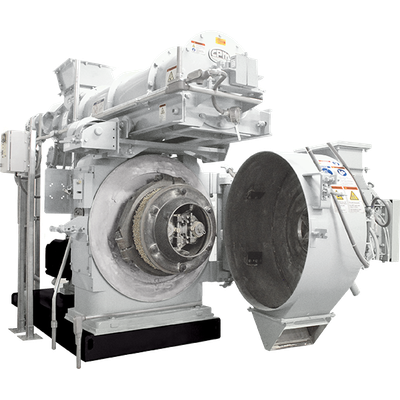

CPM - 1100 Series Pellet Mill for Small Production

The 1100 Series Pellet Mill is designed for small production-scale operations, using design principles from larger pellet mills to ensure durability and economical performance. It features components with metal-to-metal seals, a replaceable quill flange, and a stainless steel pellet chamber, making it a reliable choice for those in need of consistent production. Optional features enhance its adaptability for various processes. Suitable for producing small batches or testing new materials, it integrates with existing ERP and finance systems for automated processing, from receiving to loadout. It is backed by CPM's expertise in providing efficient solutions for pellet production.

- Positive direct gear drive provides a 98% energy transfer

- Rounded cast gear case with internal ribbing for quieter operation

- Segmented die clamps for quicker die changes

- Modular gearbox design for production flexibility

- Single motor for greater efficiency

Take your pelleting operations to the next level with trouble-free, continuous production. This pellet mill offers metal-to-metal seals between components, a replaceable quill flange, and a stainless steel pellet chamber. If you’re looking for a durable and reliable pellet mill, the 1100 Series is for you.

- Enforcer feeder available on PM 1112-4 and PM 1116-4

- Automatic grease system

CPM automation capabilities can control anything from a standalone piece of equipment to an entire processing operation. We can also integrate with your Enterprise Resource Planning (ERP) and finance systems for seamless operation.

Full Automation System: An integrated process control solution for receiving, grinding, batching, pelleting, and loadout processes.

Pelleting Automation: Automates conditioning, pelleting, cooling, post-pellet liquid addition, and routing processes.

Pellet Mill Controller: The ideal solution for pelleting control without a database.