- Home

- Companies

- The Local Exhaust & Ventilation Company ...

- Products

- Sledgehammer - Model 05-015 - 2`D X 3`W ...

Sledgehammer - Model 05-015 -2`D X 3`W Downdraft Tables

Sledgehammer ©- A series of downdraft tables designed to be a dual-purpose workstation and extraction solution. These tables draw contaminants from the source away from workers’ breathing zone without hindering movement. This unit features a max flow rate of1200 CFM

Heavy-duty Downdraft table that provides the most durable ¼” steel plate work surface (36” X 24”) on the market. The Sledgehammer ©is equipped with Jet-Pulse Cleaning that allows simple cleaning of the filter, which reduces filter costs dramatically*.

Available with:

- VFD Options

- Preventative Maintenance Pressure Gauges

These pre-engineered, ‘’Plug and Play’’ downdraft tables come complete with the following:

- Fan Capacity: 1200 CFM (2000 m3/h)

- “Nano Fiber” filter cartridge, 99.9 % efficient @ 0.5 Micron

- Direct drive fan coupled with Non-Sparking Aluminum Impeller

- 1.5 HP (1.1 KW) 120V/1/60 TEFC Direct Drive class II motor

- ’Plug & Play’ Design includes easy maneuverable wheels, Motor starter, overload protection, 12’ cord and plug)

- Flow Controller allows the flow rate to be reduced eliminating the change of porosity

- Internal dust tray

- 1/4" steel plate work surface 36” X 24” (900 X600 mm)

- 5 stage spark arrestance package including Deflection grates, 2 - Spark absorption trays (Fill with water and/or sand – by others), Baffles, expansion chamber and optional plasma cutting spark arresting surface

- Welding gun/ground clamp holder/connection

- Working booth design with back and side walls

- Jet-Pulse pneumatic filter cleaning system

- Low height design that can be easily raised to suit almost every working height

- 115 Volt:Ability to plug into any standard circuit, reducing installation costs

- Filter Cleaning System:Ability to clean by air to remove the contaminant from the filter without taking the filter out of the unit, lowering operation costs

- Integrated spark trap with water tray:Ability to pre-separate the spark before the main filter, which reduces the risk of fire

- Flame, melt and deform proof steel construction:Avoid high cost of replacement plastic parts

- Small foot print:Ability to maneuver with ease especially in narrow areas, saving space in the production area

Top 5 contaminants/processes/applications:

- VOC Fumes

- Gases

- Composite Dust

- Welding Gases

- Grinding Particles

Don`t see your contaminants? Give us a call! 1-888-862-5356 or Click our instant chatbox.

IMPORTANT: For your Health and Safety, make sure to talk to an application engineer before purchasing.

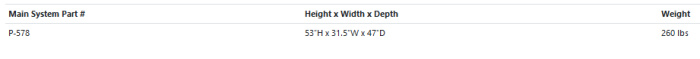

P-578

Sledgehammer Downdraft Table, self-cleaning *100% washable replacement filter cartridge with 45% more surface area and 15% higher flow rate.

- All steel construction (no plastic to deform or melt)

- Smallest footprint of any unit on the market (22 x 25 = 3.8ft2)

- Powerful 1.1 KW (1.5HP) motor 115V/1/60 UL / CSA *Complete with Motor starter, overload protection, plug and switch - Ready to use

- Dual Stage spark trap

- Cleanable filter (with water or compressed air)* *Complete with integrated filter cleaning system **AS PER CANADIAN LAW; this unit is electrically approved by CSA/ESA field evaluation.

- Replacement Filters

- Variable Frequency Drives