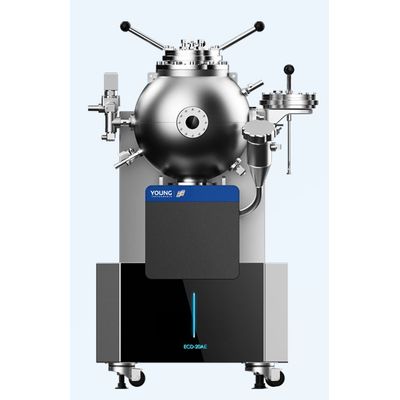

Zeal - 20L Spherical Explosion Tester

20L Spherical Explosion Tester is a professional testing instrument for determining the maximum explosion pressure, maximum explosion pressure rise rate, and explosion index of dust cloud explosion under specific testing conditions. It is mainly used for dust explosive evaluation of aluminum powder, zinc powder, plastic powder, intermediate of organic synthetic drugs, wheat powder sugar, sawdust, dyestuff, bakelite ash, milk powder, and other production and processing places.

Maximum Explosive Pressure, Maximum Explosive Pressure Rate of Rise, Explosive Index

Combustible Dust

Combustible Dust Explosion, Combustible Dust Classification, Dust Testing

- Tests the explosion parameters of dusts, gases and mixed solid/gas systems.

- Built-in international common test standards, either according to the standard parameters of the test, can also be customised.

- Chemical ignition and electrostatic ignition, suitable for different testing purposes.

- Explosion vessel with water-circulating jacket for constant temperature of the test environment

- Input the target concentration value, automatic cleaning, evacuation, and complete gas distribution as required.

- Dust dispersing device capable of completely and uniformly dispersing the dust into the explosion vessel.

- Experiments are carried out automatically without human intervention.

- Real-time display of time and pressure, more intuitive testing process.

- Experimental results include time-pressure curves, providing detailed information about the explosion.

- Remote control, to ensure the personal safety of experimental personnel.

- Adopt computer control, strong data analysis ability, accurate judgement of curve characteristics.

- Standard—— ASTM E1226, ASTM E1515, EN 14034-1, EN 14034-2, EN 14034-3, EN 14034-4, GB/T 16425 GB/T 16426, GB/T 803, ISO/IEC 6184/1, ISO/IEC 6184/2, ISO/IEC 80079-20-2

Working Environment: 5? to 45?, <85%RH

Explosive Container: 20L Ball with jacket

Vessel Pressure Resistance: Design pressure 3.0MPa@25?

Ball Material: Stainless steel 316

Ball Working Temperature: Maximum temperature 220 ?

Sphere Volume: 20L

Mezzanine Volume: 1.5L

Diffusion Pressure Sensor: Range (0~3.5)MPa, overload pressure 10.5MPa, accuracy ±0.1% FS, operating temperature (-40~105)°C

Gas Pressure Sensor: Range (0~200)kPa, overload pressure 600.0kPa, accuracy ±0.1% FS, operating temperature (-40~105)?

Explosion Pressure Detection: Detection range (0~10.0)MPa, resolution 0.001MPa, accuracy ±0.5%FS, response time <20us

Explosive Pressure Detection Channels: 2

Explosion Temperature Sensor: Detection range 0 to 1000 ?, resolution 0.01 ?

Dust Diffusion Vessel: Capacity 0.6L, pressure resistance 2.5MPa

Powder Spraying Pressure: 2MPa

Nozzle Type: Bounce Nozzle

Powder Spraying Delay Time: 30ms to 50ms

Ignition Method: Chemical ignition (customer’s own);Electrostatic Ignition (15kV, 0.5s)

Ignition Delay Time: 60ms

Explosive Pressure Data Acquisition: Maximum acquisition rate 100 ks/s, recording time 1s

Ignition Control: Support remote wireless ignition

Automatic Air Distribution: 2 gas inlets, 1 air inlet; adopts partial pressure method of air distribution, with independent pressure sensors and solenoid valves, air distribution accuracy ± 0.1%

Vacuum System: Rotary vane vacuum pump, equipped with double impact filters to prevent residual substances from clogging and contaminating the pipeline, and easy to replace

Snap Ring Diameter: 95mm

Cleaning Hole Diameter: 150mm

Viewing Window: Armoured glass, 40mm diameter

Interface: RJ45

Power Supply: 90~260VAC/47~63Hz

Power: 600W

Dimensions: 700mm×540mm×1210mm