5M - Composite Pultruded Profiles for Industrial Applications

Composite pultruded profiles are manufactured by 5M s.r.o. using the pultrusion method, employing a matrix typically composed of polyester resin with optional use of other resins like epoxide, vinylester, phenolic-acrylate, or polyurethane depending on the specific application requirements. The profiles are reinforced primarily with glass fiber or carbon fiber, which provides enhanced mechanical properties. For certain specifications, direct fibers, mats, or fabrics may also be utilized. These profiles are characterized by their low weight and superior resistance to corrosion and chemical exposure, making them suitable for diverse industrial uses. The major sectors leveraging these composite profiles include public transportation, sports equipment, electrical engineering, aerospace, and construction. The versatility and durable nature of these materials contribute significantly to performance and longevity in demanding environments.

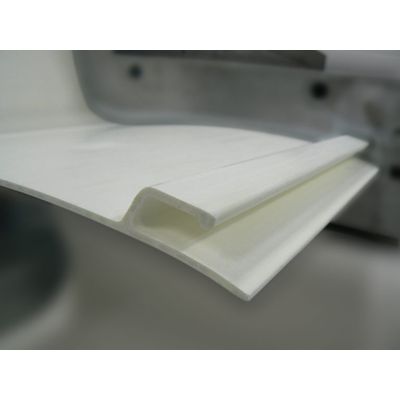

Composite (laminated plastic) profiles are well known to the wide public as fibreglass (or carbon) bars or tubes. Nevertheless, our company’s production assortment shows that a composite profile can have different shapes and thanks to our long-term experience, we are able to manufacture even very shape-complex profiles.

Our company makes composite profiles using the pultrusion method from resin and reinforcement. The matrix normally used in manufacture is polyester resin, while special applications also involve using epoxide-, vinylester-, phenolic- acrylate or polyurethane resins. The reinforcement mostly used in our applications consists of glass fibre or also carbon fibre. According to required resulting properties of a profile, we can also use direct fibres (so-called roving ones), different types of matting or fabrics, or their combination if necessary.

Thanks to predominantly their low weight and excellent resistance to corrosion and chemicals, composite profiles are used in various production sectors when a great part of our production capacity involving the making of composite profiles is mainly aimed at manufacturing public transport means, sports accessories, at applications in the electrical engineering, aerospace industry or building engineering.

- feature dimensional accuracy of the profile

- high tensile strength

- high impact strength

- corrosion resistance

- outstanding electroinsulating characteristics

- low heat conductivity and heat expansion

- specific weight

- long service life

- minimum maintenance

- constructions elements in building industry

- covering panels in busses, trams, trains

- constructions elements in aircraft production

- window frames or reinforcement of window frames

- elements in chemical industry (corrosive environments including chemical premises)

- edges on lorry box bodies

- rods in heavy-current electrical industry (insulator supporting poles of high-voltage distribution systems, supporting members of trolley systems, spacing profiles in large transformers,…)

- sport equipment (hockey sticks, arrows, bows, tents, )

- ladders