5M LETOXIT - Model LFX -Epoxy Foil Resins

LETOXIT LFX epoxy foil resins provide an efficient and safer approach to manufacturing fibreglass components with minimal environmental hazards and straightforward application. This technology hinges on the layering of dry fabric with epoxy resin and hardener, offered in a foil of defined thickness. By using this foil, which can be perforated for enhanced results, lamination is straightforward, allowing for the precise assembly of reinforced layers. After constructing the layers, air is evacuated, and the assembly undergoes curing in an oven. The process requires elevated temperatures initially to liquefy and impregnate the resin into the fabric, followed by standard curing at 120°C, though variants exist for curing at 80°C. This method supports applications needing a precise resin-to-fabric ratio, a glossy finish, and is three times faster than traditional methods. It suits various sectors, including aviation, automotive, healthcare, and sports equipment, offering notable benefits in production efficiency and cost savings.

The “5M s.r.o.” company developed and has patented a very efficient technology for manufacturing sophisticated and relatively inexpensive composite structures called LETOXIT Foil Technology, to be abbreviated LF TECHNOLOGY. It’s one of the forms of RFI (resin film infusion) technologies.

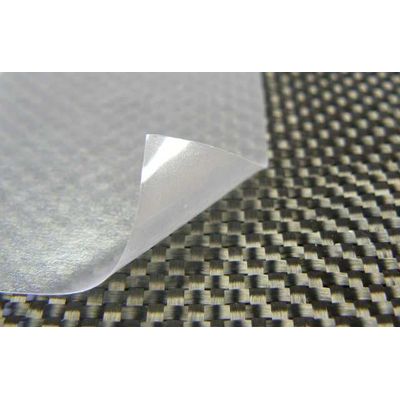

It’s an easy way how to manufacture fibreglass parts with no harmful risks, involving easy application. The principle of our technology is to interpose dry fabric with layers of resin and a hardener in the form of some foil with an exactly defined thickness, which we offer under the brand name LETOXIT® LFX.

The lamination itself is very easy, progressively putting down layers of some reinforcement (layers of fabrics) and epoxide foil LETOXIT® LFX according to required final properties of such laminated material. We recommend this phase to be done with perforating the foil LETOXIT LFX to get better results. After stacking up all layers, air is sucked out in the whole composed layer to further put it into a hardening oven. The hardening process then requires a bit higher temperatures to liquefy resin in the first phase (resin melts down because of the temperature) to consequently impregnate (saturate) the fabric. In the second stage, the resin is then hardened under standard hardening temperatures (120°C). Nevertheless, there are also other types of resin, getting hardened at even 80°C.

This production technology is suitable for all possible applications that require having nice surface with keeping a clearly defined resin and reinforcement ratio.

- Time saving production – textile is saturated and cured in one step

- No autoclave needed to use

- Dry method of lamination free of odour and harmful substances

- Three times faster method in comparison with liquid resins

- Smooth and glossy surface of final products directly from the mould with no need to apply gelcoat

- Financial costs savings when stored (compared to prepregs)

- Production of sandwich composite panels

- Aviation (floors, interior and exterior composite parts, floors)

- Car industry (production of tuning parts for motorbikes and cars)

- Health care (x-ray tables production, composite orthoses)

- Sport equipment (canoes, paddles, skis)