- Home

- Companies

- Hosokawa Micron B.V.

- Products

- Active Freeze Drying system

Active Freeze Drying system

The Active Freeze Dryer (AFD) offers unique possibilities for producing sterile bulk pharmaceuticals in one processing step, always resulting in a fine loose powder which is directly available from the product collector. Material consistencies can range from solutions, dispersions to paste and even wet solids. The key benefits of this technology are efficiency, minimal handling and a consistent, high product quality. Active Freeze Drying technology is especially suitable for pharmaceutical applications such as antibiotics, proteins, collagens and APIs.Freeze drying (lyophilisation) has been used industrially for decades. However, traditional tray-type freeze dryers are labour intensive. Hosokawa's Active Freeze Drying system eliminates this drawback and is a big step forward in the field of freeze drying thermo-sensitive bulk solids as well as in powder technology in general. Due to the agitated freeze drying process, different product characteristics can be improved without the need of post-processing steps.

The Active Freeze Drying system offers unique possibilities for freeze drying various types of materials in one processing step, always resulting in a fine loose powder which is directly available from the product collector. Material consistencies can range from solutions, dispersions to paste and even wet solids. The key benefits of this technology are efficiency, minimal handling and a consistent, high product quality.

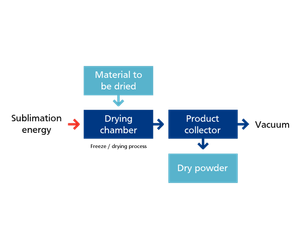

In an Active Freeze Dryer, the product is first frozen dynamically by moving it in a specially designed chamber. Whether the material to be dried starts off as a liquid, granular solid or paste, the forced motion inside the drying chamber ensures that it freezes in the form of free-flowing solid granules.

Once the product is fully frozen, a deep vacuum is applied and the sublimation starts. Heat applied to the vessel jacket is effectively distributed throughout the product due to the dynamic environment. The initially coarse, frozen granules gradually shrink as the ice structure connecting the frozen material sublimes, yielding a loose powder consisting of fine, dry particles.

As the solvent disappears, the product temperature starts to rise until it equals the jacket temperature. This marks the end of the drying process. Once the vacuum has been released, the chamber is opened and the powdered product can be discharged.

Typical applications include pharmaceuticals like antibiotics, proteins, collagens, APIs and electrolytes. Numerous successful applications are also found in food and food additive applications like herbal extracts, milk derivatives, enzymes, broth extracts, vegetables, lipids, insects, flavours, fibres, proteins and soups. This new technology has also proven its suitability to the freeze drying of special materials like nanomaterials, polymers, ceramics, pigments, fillers, lime stone, catalysts, glass powder and salts.

- Efficient

The Active Freeze Drying process is less labour intensive than the traditional tray-type process. This technology produces lump free, free-flowing powders in one single step. Consequently, the handling is significantly shorter and simpler (no manual handling or de-lumping steps), saving you time and money! - Superior quality

Due to this alternative and much faster method of freezing the substrate, the structure of the end product is different and in the majority of cases, will result in an amorphous-like structure with better (re)dispersibility and free-flowing properties. In addition to this, the particle size of the final product is often extremely fine and uniform. - Contamination-free

There is hardly any risk for contamination, which makes the Active Freeze Dryer ideal for sterile bulk pharmaceuticals. - Compact

The Active Freeze Dryer is a compact piece of equipment that requires much less floor space than conventional tray drying installations which usually comprise of horizontal vessels, freezer and tray handling machinery. Hosokawa Micron has converted all of this into a single device.