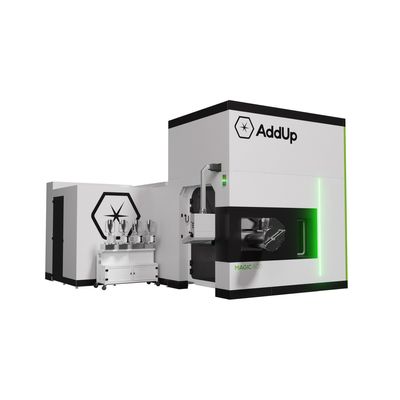

AddUp - Model Magic 800 -DED Machine

With its 2 kW laser, two heads (optional), and a working height of 1800 mm, one of the largest volume of work on the market, the Magic 800 can meet the most demanding applications. This machine is a concentrate of technology adapted to the needs of industrial DED production. It is equipped with an enclosure inerting device, which allows working with reactive powders. This feature makes it one of the few machines on the market capable of producing titanium parts.

Industry leading surface finish, with better meltpool control, and productivity built for industry, that’s what you get when you buy an AddUp DED machine. Discover our Modulo 400 for more advanced DED applications.

IN-HOUSE DESIGN NOZZLES

The Magic 800 machine is a DED additive manufacturing machine that can be equipped with two nozzles of different sizes and power. Opt for the 24Vx nozzle to make the massive sections of your parts, then automatically change during production to the 10Vx nozzle to make parts that require precision.

- The 10Vx deposition nozzle (optional) can deposit weld beads 0.8 to 1.2 mm wide, with an accuracy of 0.1 mm.

- The 24Vx deposition nozzle (standard) can deposit weld beads 1.8 to 2.2 mm wide, with an accuracy of 0.2 mm.

- Nozzle change takes a few seconds, without interrupting production.

THE BEST OF DED TECHNOLOGY

Many devices available as standard or optional on the Magic 800 make this machine a concentrate of technology. To name only a few: vibration powder dispenser for stability and reliability in the powder supply of the deposition nozzle, and automatic deposition nozzle change system, including a probe for significant productivity gains and adaptive repair applications.

The Magic 800 DED is the largest 5-axis CNC, blown powder DED machine in AddUp’s fleet. With its 2-kW laser, two exchangeable heads (optional), and an impressive build volume of 1800 mm x 1000 mm x 1000 mm.

MAGIC 800 (standard)

MACHINE SIZE:

Dimensions: L 5,9 x W 7,2 x H 4,1 m

Recommended height (under ceiling): 4,5 m

Total weight: ~20 T

DED NOZZLE:

Type: 24Vx

Laser: Ytterbium fiber - 2000 W

Optical fiber diameter: Ø 600μm

Cord width: 1,8 to 2,2 mm

Average deposition rate: 90 - 130 cm3/h

POWDER:

Number of feeders: 2 (2 available as option F)

Powder feeder technology: Vibration

Capacity: 2,5 L (approx. 13 kg of standard steel)

Powder flowrate: 1 - 30 g/min

MOVEMENTS:

Number of axis: 5 (simultaneously and continuously)

Linear axis stroke: X= 1000 mm, Y= 1800 mm, Z= 1000 mm

Rotary axis stroke: A = +/-110°, C = +/-360°

TABLE:

Table diameter: Ø 700 mm

Building volume: 1800 x 1000 x 1000 mm

Maximal load: 5 axis: 500 kg (part holder included)

3 axis: 800 kg (part holder included)

CNC:

Controller: Siemens SINUMRIK ONE

Compatability: G-code

SECURITY:

Laser: Door with laser protection glass

Exhaust filtration: 3 levels: pre-filter, HEPA, chemical filter

GAS:

Type: Argon