- Home

- Companies

- Advance Hydrau Tech Pvt Ltd.

- Products

- Advance Hydrau Tech - Continuous Baler

Advance Hydrau Tech - Continuous Baler

The continuous balers built by Advance Hydrau Tech are used to process the metal scrap in fully automated mode with continuous feeding, baling, and ejection. These are best suited for homogenous metal scraps like UBCs (Used beverage cans), CRC, car body scrap, white goods, and other such materials. To give our customers bales with the highest density and excellent results, our hydraulic baling press has a triple action mechanism.The name of the baler is derived from the continuous feed it is provided with.The metal scrap is fed continuously into the baler through a magnet, grab crane, or a conveyor. The scrap is compacted from three sides just like a triple compression baler or a three ram baler.

The triple action continuous metal baler offers benefits of short cycle time and high-density bales. The high-density bales offer tremendous efficiency in the melting process, therefore, recycling units and furnaces increase their yield and thus recover more pure metal. Continuous baler finds its application mostly in industries where metal scrap is generated constantly and in big quantities such as automotive industry, big furnaces, or melting units and industrial stamping press lines.

- Low overall operating cost

- High productivity

- Super high-density bales

- Weight of the bales can be programmed and controlled

- Increased speed of movements

- Lower cycle times through the use of high-pressure pumps

- Low energy consumption

- Easy installation

- Robust design

- Low maintenance requirements

- Easy operation with multi-display PLC-control panel

- HARDOX material is used for long life of compression chamber walls

- Bale length and density can be changed as per customer’s needs

- After-sales on-demand service

- Automatic lubrication system

- Air radiator for oil cooling

- Feeding Hopper

- Online Oil Filteration System

- Wireless Remoter

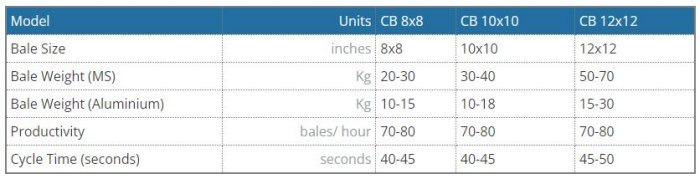

* Specifications are indicative and are subject to change as per customer’s requirement and technical advancements.

* Accessories shown in the image are not necessary to form part of the actual machine.

* All dimensions, weights and cycle time mentioned are approximate.

* Output depends on the type of the scrap material fed, feed rate and operator skills.