- Home

- Companies

- AG-Projekt

- Products

- AG-Projekt - Model PSK - Cat Screw ...

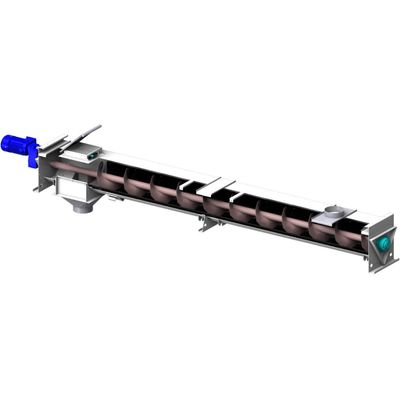

AG-Projekt - Model PSK -Cat Screw Conveyors

We manufacture PSK trough screw conveyors with a capacity of 20 to 40 t / h.

PSK manufactured by AG-PROJEKT are intended for horizontal transport of loose materials such as:

- cereal grains

- legumes

- oilseeds

- granules

- corn

- pellets

The PSK Screw Conveyor has a capacity of 20 [t / h] (PSK200 / 20) and 40 [t / h] (PSK200 / 40) is the most often required and occurring device when moving material over short distances. Pipe screw conveyors of the PSR200 / 20 and PSK200 / 40 series intended for grain transport have a modular structure, enabling easy configuration of the device depending on the user`s needs. Our offer includes PSK conveyors from 2m to 10m in length.

Recommended horizontal work position. It is possible to mount our devices at an angle ranging from 0st to 30st. Depending on the angle, the nominal capacity of the device decreases (using the same drive). The innovative solution is lining the pipe from the inside with PE-UHMW material with reduced friction coefficient.

This solution has the following advantages:

- facilitates the movement of transported material, which significantly reduces the wear of conveyor components having direct contact with the transported material

- reduces the power demand for conveyor drive,

- reduces damage to transported grains,

- noise resulting from grain movement is reduced.

This solution has the following advantages:

- facilitates the motion of the material to be transported

- significantly reduces the wear and tear of the

- reduces power consumption to drive the conveyor

- reduces damage to the transported grain

- reduced noise resulting from the movement of grain