- Home

- Companies

- Airtec Air Systems Ltd.

- Products

- Airtec - Air Knives System

Airtec - Air Knives System

Air Knives deliver a non-contact method for product drying, coating, cleaning and cooling during production and are used in the manufacture of food, automotive and industrial parts; they remove surface moisture or excess debris from products as they traverse through the manufacturing process. At Airtec, we are industry leading specialists in the design and manufacture of completely bespoke air knife systems which can be tailored exactly to your requirements. We can offer a complete service package from initial consultation and design right through to installation and commissioning.

Air knives generate and direct low pressure/high volume air. Air knives produce a highly controlled, non-contact solution for removing surface moisture or debris from virtually any product during a manufacturing process.

The air Knives are positioned at strategic positions along the manufacturing process to clean or dry the products as they traverse past.

Air is forced through the air knife slots via an Airtec industrial blower, to deliver the exit air volume and velocity needed to efficiently remove moisture or debris from virtually any product or surface during manufacture. Airtec industrial blowers are high quality robust units that are precisely load matched to provide optimum performance and efficiency.

Our bespoke air knife drying systems have been successfully implemented into a bewildering variety of different industrial applications. From swarf removal of aircraft parts to drying lobsters as part of an in-line production process, Airtec have an enviable portfolio of successful systems in virtually every industry.

Air knives have four main application areas: Drying, Cooling, Coating and Dust /debri removal .Here are some examples of how those are used in real world applications

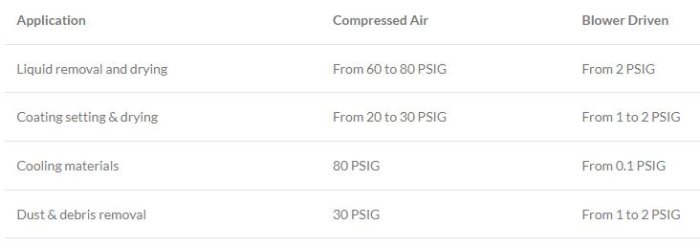

An Airtec air knife can offer any one or a combination of air delivery types to dry virtually product size or shape during manufacture. Our bespoke solutions have been integrated in many leading O.E.M suppliers in a wide variety of industries. We make different types of air knives for our customers, most notably: standard, air cannons, circular and custom. Each project is different, requiring bespoke work to be done to make sure a perfect solution is delivered. Different Air Knife uses require different pressures to accomplish their tasks. Whilst some can be quite a low pressure, drying or cooling for example, others such as liquid removal need a much higher pressure delivery.

Blower driven air knife systems offer a distinct advantage over the compressed air equivalents as much lower pressures are required with a blower driven system to achieve the same result. Upto 90% savings in terms of energy costs are therefore not un-common. The following table illustrates typical pressures required as a comparison.