- Home

- Companies

- Doosan Lentjes GmbH

- Products

- Doosan Lentjes - Air Quality Control ...

Doosan Lentjes - Air Quality Control Systems

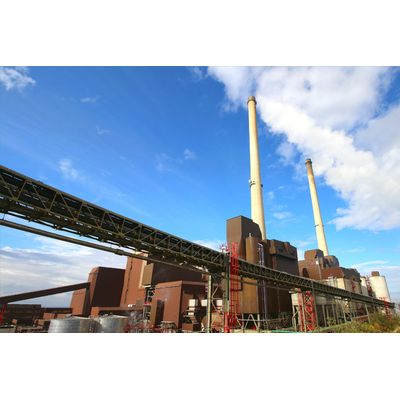

Doosan Lentjes has developed a range of flue gas cleaning processes that meet the specific requirements of waste-to-energy or sewage sludge incineration plants, power stations or industrial facilities.

We look back on decades of experience in the field of flue gas cleaning. Since 1984, we have been reliably supplying systems for gas cleaning in various projects worldwide. Whether for thermal waste treatment or sewage sludge incineration plants, power stations or industrial facilities – Doosan Lentjes offers the right concept for cleaning flue gases for your process and specific requirements.

Our competences include both (semi-)dry and wet processes for the separation of particles and pollutant gases as well as technologies for denitrification and possibilities for heat extraction from flue gases. Strict emission regulations according to the European BREF documents (Best Available Techniques Reference) or the 13th, 17th and 44th BImSchV are reliably complied with.

Depending on your individual project requirements, framework conditions and limit values to be complied with, a flexible combination of different technologies is possible, from which we design and deliver a customised solution for you.

Our flue gas cleaning systems benefit from a compact design and a small footprint. Flexible integration into existing infrastructure is possible while maintaining economic aspects. Load-optimised system operation and the associated efficient use of the operating resources employed ensure reduced operating costs.

As the Centre of Competence for flue gas cleaning within the Doosan Group, we have our own Research & Development (R&D) capabilities. Our focus is therefore always on providing you with solutions that meet or exceed the current state of the art, have a high level of competitiveness, and meet market trends.

- Compliance with strict emission regulations according to the European BREF documents or the 13th, 17th and 44th BImSchV

- Flexible combination of different technologies and systems – depending on the emission limits to be met

- Optimi5sed investment, operating and maintenance costs

Our semi-dry Circoclean® process is a well-proven, robust, wastewater-free process for the removal of various pollutants such as SO2, SO3, HCl, HF, dioxins, and furans as well as heavy metals such as mercury from flue gas.

The process can be used for plants burning biomass, refuse derived fuels (RDF) or domestic and industrial waste, in the industrial sector and downstream of coal- and oil-fired boilers. Furthermore, this process replaces a spray dryer for the treatment of wastewater from other flue gas cleaning stages.

ProcessBefore entering the circulating fluidised bed reactor (Circoclean® reactor), the absorbents are injected into the flue gas. Hydrated lime (Ca(OH)2) and activated carbon (AC) are usually used.

The flue gas flows through the reactor from below, causing the fly ash contained in the raw gas and the additives to fluidise and form a fluidised bed. Acid gases, dioxins, furans, and heavy metals are separated in this fluidised bed. Due to an intensive mass transfer and a high velocity in the circulating fluidised bed, a high separation efficiency is achieved. The optimum flue gas temperature and moisture content for the operating conditions are set by the additional injection of water into the Circoclean® reactor.

The gas then enters the fabric filter. After the separation of solid particles in the filter, a large part of the additives is returned to the Circoclean® reactor to achieve efficient use of the absorbents.

Low investment, operating and maintenance costsOur Circoclean® flue gas cleaning process benefits from an optimised design that significantly reduces the required footprint. The design eliminates the use of high wear rotating parts, which not only reduces investment costs but also maintenance expenditures. This design ensures a high degree of plant availability. The hydrated lime used as an absorbent can be obtained on site from burnt lime to further reduce operating costs.

The advantages of our semi-dry Circoclean® flue gas cleaning at a glance:- Compliance with all emission limits according to European BREF documents and 13th, 17th and 44th BImSchV

- Almost complete separation of SO3, avoiding maintenance work related to sulphuric acid corrosion problems

- Comparatively low investment costs and reduced maintenance requirements

- Wastewater-free operation, contributing to high cost-efficiency

- Input of wastewater from downstream wet treatment stages possible

- Flexibility to adapt to future, even stricter emission limits

- Compact design that allows easy retrofitting

- Optimised absorbent consumption through additive recirculation

- High plant availability

As a simple and cost-effective alternative for applications with moderate concentrations of pollutants, we offer the dry FER-DI® process (Flexible Economic Reagent Direct Injection). Acid gases such as SOx, HCl, HF as well as dioxins and furans and heavy metals such as mercury are reliably removed.

Installations are possible in plants for the thermal treatment of waste, in biomass incineration plants, in the industrial sector and downstream of coal- and oil-fired boilers.

ProcessDepending on your individual requirements, we use either sodium bicarbonate (NaHCO3) or hydrated lime (Ca(OH)2) as absorbent in combination with activated carbon (AC).

The absorbent is added directly to the hot flue gas at the outlet of the boiler. The pollutants contained in the raw gas react with the additives and are then separated in a downstream particle filter system (fabric filter). A large proportion of the solid particles separated in the fabric filter are returned to the duct area in order to make optimum use of the separation potential of the absorbent used. A part is withdrawn from the process for disposal.

Reduced costsThe FER-DI® process benefits from an even more compact plant design with minimal space requirements, which also reduces your investment costs. At the same time, the simple concept enables minimal maintenance and operating costs.

The advantages of our dry FER-DI® flue gas cleaning at a glance:- Simple process for moderate pollutant concentrations

- Compliance with all emission regulations according to BREF documents and 13th ,17th and 44th BImSchV

- Plant design in the smallest possible space

- Optimised investment, maintenance, and operating costs