- Home

- Companies

- McPhy Energy S.A.

- Products

- Alkaline McLyzer - Augmented ...

Alkaline McLyzer - Augmented Electrolysis

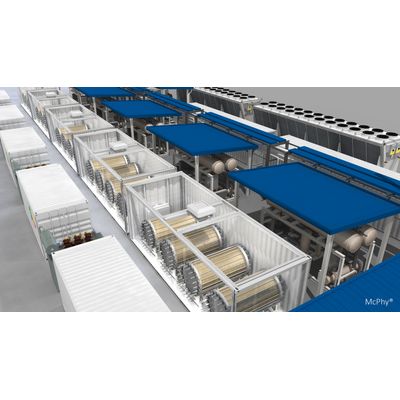

McPhy is supporting the transition of the industry, mobility and energy sectors towards a low-carbon economy, allowing customers to move away from fossil energies by mass production of low-carbon hydrogen at competitive prices. To this purpose, as a true breakthrough technology, our “Augmented McLyzer” electrolyzers combine the reliability and the maturity of pressurized alkaline technology with great flexibility. They are integrated into our large-scale (multi-MW) electrolysis platforms, specifically designed for use in the industry and heavy-duty transport sectors.

McPhy launched in 2018 its breakthrough “Augmented McLyzer” technology, a unique combination of our core expertise of high-pressure alkaline electrolysis and the integration of new generation electrodes with high current density (doubled compared to standard electrodes) that significantly increase the performance of our equipment, all within a compact design.

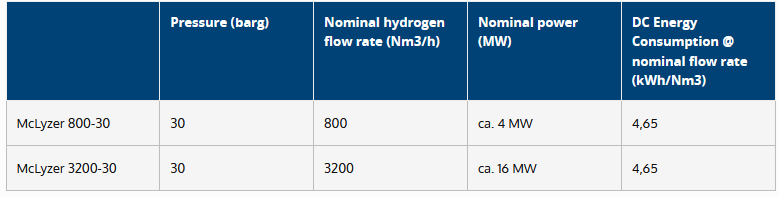

The solution is fully modularized and based on a 1 / 4 / 16 / 100+ MW module design , used as a “building block”. Our systems produce low-carbon hydrogen directly at 30 bar, and are designed to scale up with your operating rhythm.

- High energy efficiency

- Economic competitiveness: Best TCO (Total Cost of Ownership) in its category, with a delivery pressure of 30 bar from the electrolyzer, significantly decreasing the energy demand which would be required for further compression (low, medium and high pressure)

- “Bigger scale, lower costs”: The very large scale roll-out of hydrogen solutions will enable a drastic reduction in costs

- Safety: in-series simulations and modeling to take the quality and safety of our equipment to unprecedented levels

- Very rapid dynamic response offering the required flexibility for the power-market led operation, fully optimizing your investment

- A modularized and scalable architecture based on a 4 MW core module used like a building block

- Robustness: A prerequisite for industry players

- Easy to install: Stacks and BOP (balance of plant) are manufactured by McPhy, on-site assembly for customers is limited to interconnections

This multi-MW range is specifically designed towards the large-scale decarbonation of the industry, mobility & energy sectors:

- Petrol and gas refineries: fuel desulfurization, e-fuels, etc.

- Chemical processing: methanol, synthesis of ammonia for fertilizers, etc.

- And also: steel mills, coal-fired plants, thermal power stations (cooling system for alternators), metallurgy, glass production, electronic components, etc.

- Large-capacity hydrogen stations: not only for large captive fleets (utility vehicles or public stations for passenger cars), but also to refill heavy-duty transport modes (such as buses, trucks, trains, boats, etc.).