Ateco - Aluminium Internal Floating Roof

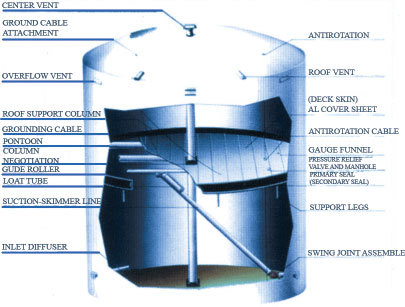

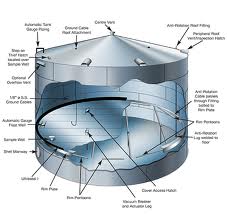

Ateco offer various designs of internal floating roofs, pontoon and full contact types, that meet and in most cases exceed the requirements of API 650 Appendix H. Although there is a fundamental difference in the design of each type of roof, many of their features and accessories are the same - selection is primarily based upon the preference of the owner. The pontoon internal floating roof is without doubt the most cost effective type due to ease of assembly and installation. All component parts can be passed through a standard tank shell manhole. There is no welding required at site and the complete installation can normally be carried out in a matter of weeks.

Ateco Aluminium Internal Floating Roof uses a peripheral rim profile custom made to suit the nominal tank diameter this ensure that saturated hydro carbon vapours are trapped and do not escape to atmosphere and can accommodate both primary mechanical shoe seal and a secondary seal without additional modifications.

Where the stored product is not compatible with aluminium the Ateco Internal Floating Roof is offered with a hybrid design using stainless steel or anodized steel for parts in contact with the stored product. Both the pontoon and full contact are offered as a complete stainless steel design.

Ateco offer as standard a simple double polyethylene foam seal on all internal floating roofs but if necessary can supply various alternative seal systems including mechanical primary seal and a secondary seal.

Ateco Aluminium Internal Floating Roofs can be cable suspended from either cone roof tanks or aluminium geodesic dome roofs, this option allows roof height adjustments to be completed from the outside of the tank and with no leg structure under the roof, cleaning inspection and repairs to the tank bottom are simplified.

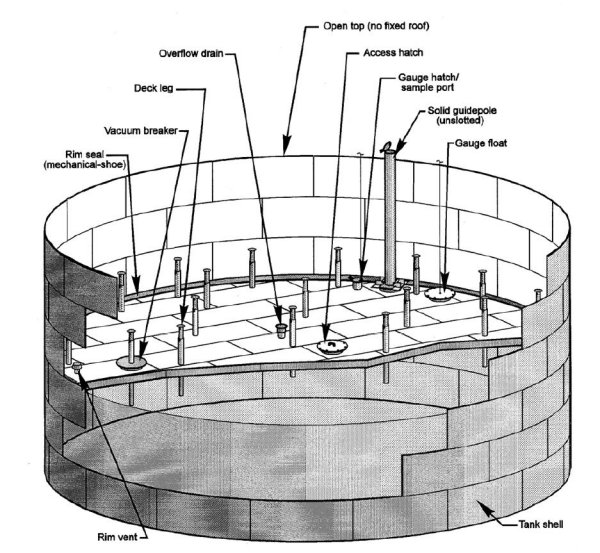

Ateco offers a large number of accessories to meet all operational requirements of the aluminium internal floating roofs; however the standard accessories including:

- Fixed Legs

- Simple Double Polyurethane Foam Seal

- Anti - rotation system

- Grounding cables

- Pressure/Vacuum Relief Vent

- Manway - Access Ladder - Ladder platform

- Gauging Funnel

- Deck Drain

The Robust Pontoon Aluminium Internal Floating Roof has standard 254 mm (10 ins) diameter by 2 mm thick extruded aluminium alloy pontoons and 0.5 mm thick aluminium sheet. The pontoons are suspended from the basic structure.

The Ultimate Pontoon Aluminium Internal Floating Roof has standard 200 mm (8 ins) diameter by 2 mm thick extruded aluminium alloy pontoons and 0.5 mm thick aluminium sheet. The pontoons are an integral component of the basic structure.

The Alumax Ultra 2000 Internal Floating Roof is an upgrade to the very successful Ateco Ultimate Internal Floating Roof and has been introduced to satisfy customer requirements for an internal floating roof that can accommodate storage tanks with a high frequency for filling and discharge of product. Designed to withstand loads up to 1000 lbs/sqft, this makes the Alumax Ultra 2000 Internal Floating Roof one of the strongest but most flexible internal floating roofs on the market today.

The high quality Alumax Ultra 2000 Internal Floating Roof obviously complies with, but in most cases exceeds, the requirements of the industry standard for internal floating roofs – API 650 Appendix H

The main design features of the Alumax Ultra 2000 can be summarised as follows:-

- Can accommodate any type of seal system including the Mechanical Primary Shoe Plates Seal or Simple Wiper Seals

- Roof leg supports connect to the main beams of the structure and not to the pontoons

- Deck Sheeting is a nominal 0.6 mm thick

- Standard 254 mm (10”) diameter pontoons are not structural components but are independently connected to the main structures, additionally the seamless 2.6 mm thick aluminium pontoons are fitted with a test port and tested at the manufacturing facility before being sent to the customer

- Extruded rim channel ensures consistent rim gap and if necessary can be manufacture to suit a particular tank profile.

- Option to suspend from the tank roof.

The Alumax Ultra 2000 Internal Flaoting Roof is compatible with most stored products being manufactured as an all-aluminium alloy product, all stainless steel or a combination of both with stainless steel for the parts in direct contact with store product.

Installation is quick and efficient as all parts of the internal floating are sent to site completely prefabricated, no welding is required to complete the assembly and all component parts fit through a standard tank 24 ins shell manway.

The Alumax Ultra 2000 Internal Floating Roof is a long term costs effective vapour control product designed to provide many years of maintenance free service.

The honeycomb modular panel design of the Ateco Full Contact Internal Floating Roof ensures that there is no vapour space between the surface of the product and the underside of the roof sheet.

The panel skin is 0.5 mm thick; each panel is approximately 1500 mm x 3000 mm and pressure tested in our workshop.

To prepare our most competive quotation it is important that the correct information is sent to us; this should include the following:

- Nominal diameter of the tank

- Type of Internal Floating Roof required i.e. Pontoon or Full Contact

- Details of Stored Product

- Type of seal system required i.e. Mechanical or Simple Wiper

- Additional accessories

We recommend that you read carefully the Standard Terms and Conditions for Quotation (Item 14.1002) and of course look at the Technical Details included in the Download Section of the Ateco Web Site where full details of the Ateco Aluminium Internal Floating Roofs are included.