Enerpat Group

- Home

- Companies

- Enerpat Group

- Products

- Enerpat - Model ERS - Aluminum Copper ...

Enerpat - Model ERS -Aluminum Copper Radiator Recycling Line

FromEnerpat Group

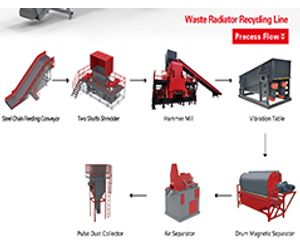

ENERPAT Waste Radiator Recycling Line designed for crushing radiators, removing steel, separating copper and aluminum, capacity from 300 kgs/h up to 3500 kgs/h. The separating rates up to 99%. Adopting UK technology, 100% high quality with competitive price.

Most popular related searches

radiator recycling plant

magnetic drum separation

magnetic drum separator

radiator recycling

recycling plant

air separator

air separation

hammer mill

waste radiator recycling

recycling plant engineering

- Steel Chain made conveyor belt,stable and strong enough for radiator

- Motor drive the conveyor shaft directly,more effective

- Connected to the Electric Box PLC,Speed adjustable according to the Hammer Mill working condition

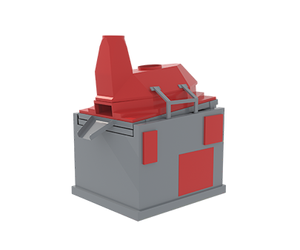

- Used for shredding radiators into smaller pieces

- International Top Brand machine parts like SIEMENS motor,BONENG gearbox,SCHNEIDER electric system,SKF bearing,etc

- German material blades like Hardox or Dillinger

- High-Strength Cutter Shaft Structure,With HARDOX 500 Wearing Plate on the shaft for protection

- After the crushing chamber is welded, the overall stress relief is annealed, and it is processed and bored by high-precision numerical control to ensure long-term high-load operation of the equipmen

- There has sensor inside of the crusher can recognize abnormal material ,It can give instructions to the crusher if meet some hard materials can not crush, to discharge abnormal material automatically

- There has rail for the screen,just loose 8 pcs screws,use forklift to pull it, then you can replace the screen. Two minutes is enough

- We have hydraulic system which can assist us to change the hammers and Pins

- With special Springs installed below the Crusher,it can efficiently reduce the machine vibration when working

- Disperse the end products from Hammer Mill by vibration

- Send the materials to the following Drum Magnetic Separator Evenly

- Separate the steel from the materials

- Copper and Aluminum go for the following Air Separator

Separating the copper and aluminum by this air separator

Automatic pulse dust removal,can collection dust efficiently from the whole production line