AMI - Model 2001LC -Trace Oxygen Analyzer

The MODEL 2001LC is a compact, cost-effective solution for measuring trace oxygen without sacrificing accuracy or reliability. The 2000LC is designed for general purpose, panel mounted applications and is outfitted with a complete sample system using AMI’s patented ELIMINATOR CELL BLOCK™ and ultra-fast oxygen sensor technologies. Key features include simple front panel senor access, compact size, 10-user selectable analog output ranges, 2-independent fully adjustable oxygen concentration alarms, and an isolated 4-20ma output, and the unit is virtually maintenance-free.

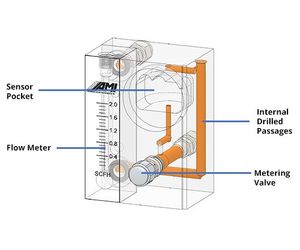

Eliminator Cell Block for a Leak-Free Design

The patented ELIMINATOR CELL BLOCK™ provides a unique, compact sample system approach and a flow-efficient sensor pocket machined into a solid metallic block. Precision cross-drilled intersecting gas passages eliminate the need for long lengths of tubing and leak-prone compression fittings. Additionally, we have engineered the metering valve and flow meter to be an integral part of the ELIMINATOR CELL BLOCK. It also provides the user with direct front panel access for installing and replacing sensors, and the ability to air calibrate the analyzer, all without the need for disassembly or tools.

The 2001LC combined with AMI’s patented oxygen sensors that deliver unmatched performance for ultra-fast response times, accuracy, and reliability. Every sensor undergoes an intense battery of tests to ensure they meet our strict quality control standards. Our trace and percent oxygen sensors operate safely, accurately, and reliably in virtually all gas streams.

The MODEL 2001LC is the perfect low-cost solution for trace O2 measurements requiring a complete sample system and limited key features. It offers the same reliability, accuracy and repeatability of other AMI Analyzers while including multiple output ranges, dual independent alarms, and intuitive controls. This virtually maintenance-free oxygen analyzer is a very cost-effective option for general purpose applications.

ELIMINATOR CELL BLOCK™

- Contains a Complete Sample System with all components, including the flow meter, metering valve, pressure sensor and 3-way Selection (Sample/Span/Off) Valve, fully integrated

ALARMS

- 2 fully adjustable concentration alarms with configurable Alarm logic and Relay Contacts, featuring:

- Alarm Bypass

ANALOG OUTPUTS

- 4 − 20mA isolated output signals

The AMI model 2001LC is the ideal solution for measuring trace oxygen in a wide range of applications in a general purpose environment. In a small size, and at very low cost, it provides a complete electronic package and sample system using AMI’s patented cell block technology.

- Display reads oxygen from 0.05ppm up to 25.0% with no range changes

- Analog output and alarms can be configured to operate over any of ten ranges from 0-10ppm to 0-25% for best resolution

- Analog output 4-20mA, isolated.

- Complete sample system built in to AMI’s patented cell block.

- Very rapid response time from air to low ppm levels.

- Easily replaceable sensor, no tools required.

- T-2 sensor resistant to 10ppm H2S standard.

- Simple, versatile installation.

- Operates off 10-28VDC with very low power consumption

- AC-DC converter provided

- 2 independent, fully adjustable alarm settings with relay contacts.

- Oxygen Sensor life indication.

Unlike competitive analyzers, AMI sensor replacement requires minimal downtime due to the front panel sensor access and the patented AMI cell block. Typical time from a one minute air exposure to 10ppm is under 15 minutes. Trace oxygen analyzers are essentially leak detectors. AMI’s patented cell block allows the analyzer to be built with almost no possibility of internal leaking, with minimal volume and with front-panel sensor access. All sample handling components – the flow meter and needle valve – are integrated into a solid metal block. Connections between them are drilled passages. The result is a highly reliable sample system with all necessary components provided, and a very fast “come-down” time – when a sensor is replaced, or calibrated on air with a 1 minute exposure (at 70°F), it takes about 15 minutes for it to come down to below 10ppm. Competitive analyzers typically take hours. ). As a result it is practical to accurately calibrate this analyzer on air and have it back on line within a very short time.

The AMI T-2 trace oxygen sensor is inherently faster than competitive sensors due to its metallic body and large active electrode area. It is also naturally resistive to hydrogen sulfide up to 10ppm H2S over its warrantied life, and may be used in samples containing high levels of CO2 with no ill effects.

The sensor is immediately accessible on the front panel of the analyzer, and can be replaced in seconds. It is not necessary to expose the sensor to air unshorted while installing it as is the case with most analyzers (which significantly increases their come-down time. The 2001LC provides a standard set of features for trace oxygen analysis at an unprecedentedly low cost.

- Trace oxygen measurement from 0.05ppm to 25%.

- Unaffected by sample flow rate changes between 0.1 – 5 SCFH.

- Standard AMI T-2 trace electrochemical sensor.

- Panel mount.

- Compact size.

- 10 user selectable output ranges.

- 3 ½ digit LCD.

- 2 fully adjustable oxygen concentration alarms• RFI protected.

- Isolated 4-20mA. analog output signal.

- Power requirements: 10-28VDC

- Low original cost and virtually maintenance free over its entire life.

- Area Classification: Designed to meet General Purpose requirements.

- 2 year warranty for analyzer, parts and labor.

- 6 month sensor warranty.

- 2001LC Series Standard ranges:

- 0 – 10 ppm, 0 – 50ppm, 0 –100 ppm, 0 – 500 ppm, 0 – 1000ppm, 0 – 5000 ppm, 0 – 1%, 0 – 5%, 0 – 10%, 0 –25%

- Sensitivity: 0.5% of full scale

- Repeatability: +/- 1% of full scale at constant temperature

- Operating temperature: 41°F to 113°F

- Humidity: < 95%, non-condensing

- Maximum inlet pressure: 100psig.

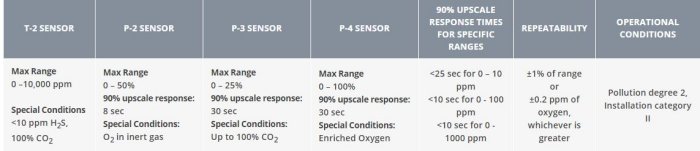

- Operational conditions: Pollution degree 2, Installation category I I.

- Drift: +/- 1% of full scale in 4 weeks at constant temperature (dependent on sensor)

- Expected cell life: 9 months to 2 years.

- Response times:

- 90% of full scale in less than:

- 0 – 10 ppm 25 sec

- 0 – 100 ppm 10 sec

- 0 – 1000 ppm 10 sec

- Output: 4-20mA isolated.

- Alarm contacts: 230/117VAC @ 5A, or 28VDC @ 5A, resistive

- Power requirements: 24VDC <10W.

- Absolute Maximum Power voltage 28VDC

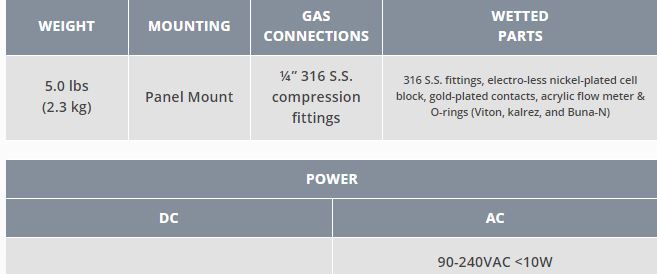

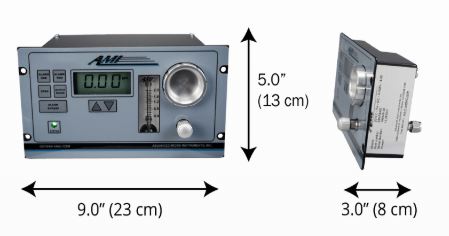

- Overall dimensions: 9” w x 5” h x 3” d

- Weight 5 lbs