- Home

- Companies

- RLC Technologies, Inc.

- Products

- RLC Technologies - Model ATDU - ...

RLC Technologies - Model ATDU -Anaerobic Thermal Desorption Units

RLC Technologies Anaerobic Thermal Desorption Unit (ATDU) is an complete waste processing plant built around an indirect fired rotary drum. Included equipment includes the vapor recovery unit, oil water separation, solids discharge and conditioning system and centralized plant controls. Every ATDU manufactured is designed to meet our customers specific performance requirements. Applications include the treatment of various waste streams including refinery waste, drill cuttings, thank and tanker bottoms, centrifuge cake, soils contaminated with PCBs, PAHs and RCRA hazardous wastes.

The ATDU is built with drum sizes ranging from 54 to 84 inches in diameter and 48 feet in length. An extended length drum can be provided to further increase the system capacity. As an option, the plant can be equipped with provisions to allow non-condensable process gases generated in the ATDU which pass through the Vapor Recovery Unit to be recirculated and utilized in the ATDU furnace. Our systems are designed to meet applicable local requirements including but not limited to the latest CE, ATEX and Ex guidelines.

Normally the material is transferred to the receiving hopper of the feed system using a front-end loader or crane. An inclined conveyor takes the material from the hopper and transfers the feed to the ATDU through a double tipping valve assembly. Material to be furnished to the ATDU is to be all two- (2) inch minus (5 cm).

The ATDU is an indirectly heated rotary drum, which is operated in a parallel flow configuration. The burner flame and exhaust gases do not come into contact with the contaminated material. The drum rotates within an insulated chamber, which can be heated by combination fuel burners capable of burning natural gas, fuel oil, syngas, or propane. As the drum rotates, the surface of the contaminated material exposed to the metal surface is continuously renewed which facilitates the transfer of heat from the heated chamber through the drum to the material. The material is heated to a sufficient temperature to volatilize the contaminants. This is achieved under anaerobic conditions thereby preventing oxidation of the hydrocarbons or chemical compound.

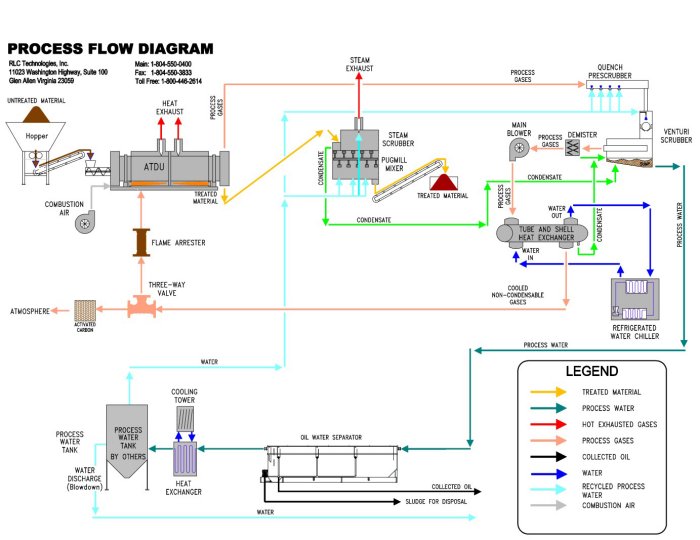

The processed solid material is discharged from the ATDU through a double tipping valve to a pugmill mixer-cooler (standard) where water is injected and mixed for direct contact material cooling. Optional jacketed screw conveyors are available for indirect cooling. With either option the hot discharged material from ATDU is cooled using either direct or indirect contact with water. After exiting the ATDU all process gases undergo a recovery/condensation and cooling process in the Vapor Recovery Unit (VRU). The condensables are processed in the Oil Water Separator (OWS) which is an integral part of the primary Water Treatment Unit (WTU). The recovered water and sludge from the WTU are stored in tanks or roll offs as required by operator.

RLC Technologies innovative technology is based on an Indirect-heated rotary desorber system which employs the use of an oxygen-deficient atmosphere while desorbing / separating volatile and semi-volatile organic compounds from the solids.

Unlike direct-flame fired systems, which create an oxygen rich, environmentally harmful atmosphere, an ATDU system virtually eliminates oxidation and the formation of hazardous compounds.

The feed system is the process of introducing and metering the feed into the ATDU plant. The feed system begins with a feed hopper, which has a variable speed screw conveyor live bottom. The design insures a steady feed supply to the ATDU while minimizing bridge formation. The material is conveyed from the feed hopper by conveyor belt equipped with a belt scale to determine the feed rate into the ATDU. A magnet located above the belt conveyor, prevents tramp metal from entering the ATDU. In order to prevent air leakage into the ATDU, the feed material passes through a double tipping valve (airlock) before entering into the ATDU chamber for thermal processing.

The material enters the ATDU and depending on the application, can be heated up to 1,400ºF (760ºC). The ATDU is equipped with a variable speed rotary drum drive and adjustable slope. The rotational speed and the slope of the rotary desorber control the flow of the feed through the unit. Depending on throughput, material residence times over sixty minutes can be realized.

The processed solids leave the ATDU via a high temperature resistant screw conveyor through a double tipping valve (airlock). The airlock ensures that oxygen-deficient conditions within the ATDU are maintained. The solids are cooled and hydrated in a mixing chamber. Water is introduced in the mixer/cooler to prevent fugitive dust and to protect equipment and personnel from the hot solids. Conveyor then transfers the conditioned material to a storage area.

Optional indirect cooling screws are available for applications requiring zero moisture content in discharged solids or where clean water is not readily available.

The process gasses leaving the ATDU are normally between 800ºF - 1000ºF (430ºC - 540ºC). The volume of gasses to be treated depends on the contaminants and the feed rate through the plant. The off-gas flow rate can range at approximately 1000-5000 ACFM (30 - 140 m3/min). The gases exiting the ATDU pass through a mechanical collector designed to remove approximately 50 - 60 percent of the dust from the ATDU. It collects the larger particulate matter from the exhaust gas stream prior to the Scrubbers. The collected dust is then discharged through air-sealed valve into the soil-conditioned system. After the mechanical collector, the gases first pass through the Pre-Scrubber, where they are scrubbed with water to reduce the temperature and remove most of the oil and the remaining particulate matter. In the pre-scrubber, the temperatures of the gasses are reduced to below 200ºF (90ºC). The gasses are then further scrubbed utilizing a Venturi Scrubber where the temperatures are nominally reduced to below 130ºF (55ºC). The Venturi Scrubber will remove almost all the remaining particulate from the gas stream. However, to achieve greater removal efficiency an additional separator with Demister is implemented after the Venturi. At or below approximately 130ºF (55ºC) temperature range virtually all hydrocarbon vapors in the gas stream have been condensed out. The VRU employs an indirect Heat Exchanger/Condenser in conjunction with a chiller to further reduce the process gas temperature and any remaining hydrocarbon residues in the gas stream. After the Heat Exchanger/Condenser, the volume of the gases will be reduced to less than 100 ACFM (3 m3/min). In cases where volatile light ends are still detected in the gas stream, they may undergo a final treatment through one of several options including activated carbon, bio-filter or thermal oxidation inside the ATDU furnace.

The Water Treatment Unit is designed to separate the process oil-water-solid mixture after the VRU into three separate streams of oil, water, and solids and to cool the stream of process water for further use in the VRU scrubber system.

The process mixture undergoes a primary separation through an Interceptor before entering the Oil / Water Separator(s) for more fine separation.

The entire ATDU plant is centrally controlled through the pre-wired and factory tested central control room. The primary controls cabinet is wired to the provided motor control center and houses the DCS and burner management system. A customized Windows based Human Machine Interface (HMI) software package is provided to serve as the operators primary point of control. The HMI monitors and records all aspects of plant operation and presents the information in the form of a clear, intuitive visual interface. Process data is displayed on the operating screen in real time and is stored in the systems memory for one year. This information can be downloaded from the control system to produce weekly operational reports.

This feature is designed to enable the operator to improve system capacity, optimize fuel consumption, and protect the ATDU equipment against accidental malfunctions. On-site training by the factory trained technicians is furnished to familiarize the plant operators with all the operational and maintenance aspects of the plant. The solids collected in the water treatment system are pumped into a separate area for re-treatment into the ATDU feed or for disposal.

Process Benefits

- Environmentally friendly nature

Our technology eliminates the need for land disposal or incineration and meet or exceed the most strengthen clean up criteria.

- Waste minimization / recycling

Our technology can produce a product that does have commercial value.

- Large treatment capability

Basically any compound, organic or inorganic that could be converted to a higher volatile substance and whose boiling point is reachable using our equipment can be removed from a stable matrix and further recycled.

- 24 hours year round operation

Our plants are designed to operate about 90 percent of the time within a 24 hours year round operational schedule.

Design Benefits

- Custom design

Our plants are custom designed for each specific application depending of the type of contaminated material and the customer`s specific needs. In addition each one of the ATDU plant we build is constantly improving in design and performance.

- Low maintenance design

Our special design, additions, and provisions enable our equipment to operate successfully with minimum required maintenance.

- Mobility / Emergency response

Our plants can be easy placed on trailers and transported to remote sites. With the quick electrical disconnects provided our plants allow easy mobilization and demobilization.

- Sophisticated control and safety system

Our equipment is completed with the last-to-date sophisticated and reliable control and safety system, which assures stable operations and virtually eliminates the risk of accidents.

- Worldwide on site assistance

We want our clients to operate properly and to produce results. Therefore our experienced startup specialists provide worldwide training and on site assistance during the plant Setup, Startup, and performance thereafter. We are ready to provide our clients with spare parts, technical data, and consultations as needed.

Financial Benefits

- Competitive price

We structure our business in a way that we are able to offer our clients internationally competitive prices.

- Cost effectiveness

Transforming a waste to a product that has commercial value, low maintenance design, high quality components, stable and reliable operations, and mobility are all benefits that enable our client to operate in a most cost-effective way.

- One year full warranty

RLCT offers One (1) year warranty with respect to its equipment.

- Suitable payment terms

We are open to use different INCOTERMS terms when pricing our equipment and we are open to discuss different payment terms and payment instruments with our clients.