- Home

- Companies

- Anyang Lishi Industrial Co., Ltd

- Products

- Anyang-Lishi - Ferrosilicon 72%

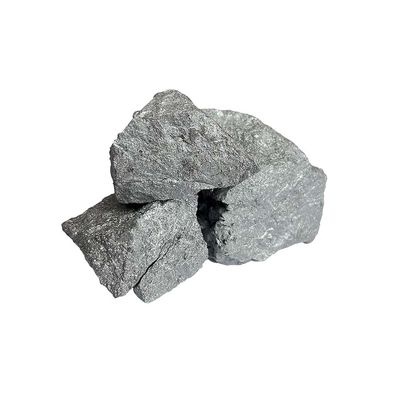

Anyang-Lishi - Ferrosilicon 72%

Ferrosilicon 72% is a common and popular model in Ferroalloy with a silver grey surface, it is mostly used as the inoculant and nodulizer in the casting industry and steel making. Ferro silicon 72 Lump, as an additive in the production process of ferrous metals, will change several properties of the ferroalloy. The corrosion resistance of the new compound was improved by adding ferrosilicon 72% of into the alloy. In the meantime, the high temperature and heat resistance of new alloys is increased.

Ferrosilicon 72% has many applications, such as in the production of carbon steel, stainless steel, and magnesium metal. Applications in other alloy production include the manufacture of silicon steel for electric motors and iron cores and coatings used during arc welding.

Production Process of Ferrosilicon 72#

Most of the ferrosilicon 72% for sale is silicon mixed with coke and then in the reduction process of rolling scale, scrap iron, or other iron sources. The production equipment of ferrosilicon 72% is a submerged arc reduction furnace. The dosage of iron raw materials controls the silicon content of ferrosilicon. In producing high-purity ferrosilicon, in addition to selecting pure silica and reducing agents, out-of-furnace refining is also required to reduce impurities such as aluminum, calcium, and carbon in the alloy. Ferrosilicon containing Si≤65% can be smelted in a closed electric furnace. Ferrosilicon with Si≥70% is smelted in open or semi-closed electric furnaces.

The Raw Material Of Smelting Ferrosilicon

The raw materials for smelting ferrosilicon are silica, carbonaceous reducing agent, and iron raw materials.

Silica

Requires SiO2>97%, Al2O3

Carbonaceous reducing agent

The carbonaceous reducing agent is required to have high fixed carbon, low ash content, and volatile matter, high specific resistance, large porosity, good chemical reactivity, good high-temperature thermal stability, and certain mechanical strength. Carbonaceous commonly used in reducing agents include metallurgical coke, gas coal coke, petroleum coke, bituminous coal, dry distillation coal, etc. Using bituminous coal as part of the reducing agent can improve the smelting operation and reduce the fluctuation of furnace conditions. Through the comprehensive combination of various reducing agents, the operating resistance, input electrical power, and electrical efficiency of the furnace can be improved.

Iron raw material

There are two kinds of iron raw materials commonly used: (1) Steel filings. For ordinary carbon steel filings, the coil length should not exceed 100mm, the iron content should be > 95%, and alloy steel filings, non-ferrous metal filings, and pig iron filings should not be mixed. (2) Iron ore. The iron ore used for smelting 75% Si ferrosilicon contains Fe≥60%, CaO≤1.0%, SiO2≤10%, P≤0.1%, S≤0.01%, preferably iron ore concentrate pellets, or can be oxidized by rolling steel Iron sheet; iron silicate ore can also be used to smelt ferrosilicon with Si≤50%.

Ferrosilicon 72# of Anyang Lishi Industrial

Anyang Lishi Industrial has been engaged in ferrosilicon 72% for 20 years, with rich production experiences and excellent product quality, a good reputation, and thoughtful after-sales service. Ferro silicon has an important useful in ferroalloy, It is widely used in the smelting industry, improvement of steel quality and purification of impurities in the steel. The more attractive smelter is the cheap price of Fesi because it can greatly reduce the cost of casting. Also, We can produce ferrosilicon alloys of various sizes and also can customize them as powder, granule, and lump.

Ferrosilicon 72% widely used in steel making, iron casting, and low-carbon ferroalloy production:

- In the industry of steelmaking, ferrosilicon is used as a deoxidizer and alloying agent for precipitation and diffusion deoxidation. Adding a certain amount of ferrosilicon to steel can significantly improve the strength, hardness, elasticity, and permeability of steel.

- Ferrosilicon 72% is the nodulizing agent and alloying agent in cast iron, especially in nodular cast iron, adding ferrosilicon 72% to cast iron can prevent the formation of carbides and promote the precipitation and spheroidization of graphite. Then the mechanical properties can be the same as steel.

- High silicon ferrosilicon can be used in the ferroalloy industry to produce low-carbon (LC) reducing agents.

- FeSi powder 72% can be used as a suspending phase in the mineral dressing industry and as a coating for welding electrodes in electrode manufacturing.