Anyang Lishi - Ferrosilicon

Ferrosilicon(FeSi) is made from semi-coke, silica, steel chips, and other products as raw materials, and is smelted by continuous operation in an open or semi-closed reduction furnace. The main uses of ferrosilicon are deoxidizers and alloying agents for steelmaking, inoculants, and nodularizing agents for cast iron, and are also widely used in magnesium metal and chemical industries.

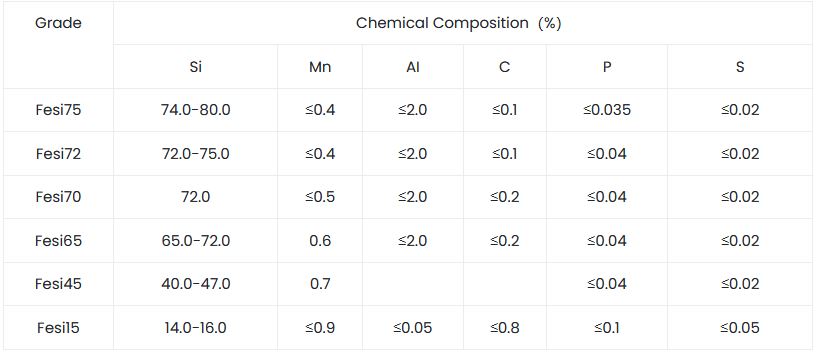

Ferro Silicon Grade: FeSi75/ FeSi72/ FeSi70/ FeSi65; FeSi45/ FeSi15.

The appearance of ferrosilicon is silver gray with a metallic luster, which can be processed into ferrosilicon powder, ferrosilicon lump, or ferrosilicon granule according to customer requirements.

Chemical Composition of FeSi: Si, Al, Ca, Mn, Cr, P, S, C, Fe, and other elements.

Raw materials and electricity consumption of every ton of ferrosilicon

- Silica: 1780~1850kg,

- Coke: 890~930kg,

- Steel shavings: 220~230kg,

- Electrode paste: 45~55kg,

- Power consumption: 8400~9000kWh/t.

Anyang Lishi Industrial Co., Ltd. is a professional ferro silicon supplier with more than 20 years experience of in manufacturing and trading. Anyang Lishi Industrial provides ferrosilicon powders (including milled ferrosilicon and atomized ferrosilicon) and ferrosilicon lumps with any particle sizes and content. Anyang Lishi Industrial is an expert in ferrosilicon 75#, ferrosilicon72#, etc. We are a professional ferrosilicon alloy manufacturer, we can give our customers professional advice and the price of ferrosilicon.

- Deoxidizer: Ferrosilicon can ensure the quality of steel during the steelmaking process while being used as a deoxidizer for precipitation and diffusion deoxidation.

- Alloying Agent: Ferro silicon can significantly improve the strength, hardness, and elasticity of steel while adding it to steelmaking.

- Inoculant and Nodulizer: Ferrosilicon can be used as an inoculant and spheroidizer in the cast iron industry. The ferrosilicon can prevent the iron to format carbides and concurrently promote the precipitation and spheroidization of graphite.

- Reducing Agent: High silicon ferrosilicon has a very low content of carbon, ferro silicon is a reducing agent for producing low-carbon ferroalloys in the ferroalloy industry.

- Magnesium smelting: 75# ferrosilicon is often used in the high-temperature smelting process of metal magnesium.

- Suspended phase: Milled silicon and atomized silicon can be used in the mineral processing industry as the suspended phase.

- Coating: Ferrosilicon powder can be used as a coating for welding rods.

Among the above usage, the steelmaking industry, the foundry industry, and the ferroalloy industry are the largest users, which consume more than 90% of ferrosilicon. Among the different grades of ferrosilicon, 75# ferrosilicon is the most widely used. In the steelmaking industry, it takes about 3-5kg of 75# ferrosilicon to produce 1T steel.