- Home

- Companies

- Automated Precision Inc (API)

- Products

- API - Model SMR - Break-Resistant ...

API - Model SMR -Break-Resistant Spherically Mounted Retroreflectors

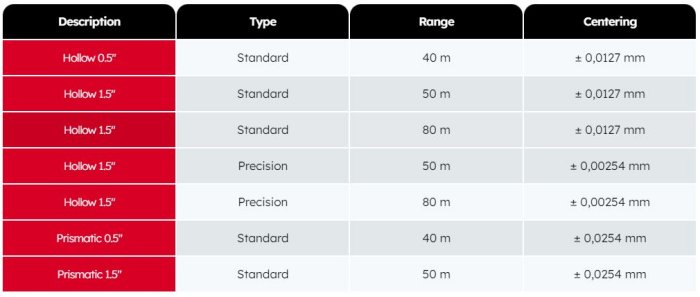

Break resistant with one piece optic can track over 80m with optical centering accuracy down to ± 2.5 microns for line of sight laser tracker measurements.

What is SMR?

A Spherically Mounted Retroreflector (SMR) is a precision measurement tool used with laser trackers. It’s a small, hollow sphere containing a three-mirror retroreflector that sends incoming laser light back to its source. This allows the tracker to accurately gauge the SMR’s spatial position.

Who is this for?

An SMR is for professionals in industries such as manufacturing, aerospace, and automotive, who need precise measurements for tasks like alignment, calibration, inspection, and assembly verification. It’s particularly useful for those utilizing laser trackers and is the main accessory for the Radian Laser Tracker.

- Under 2,5 µM: Centering

- 80 M: Max. Range

- One-Piece: Optics

- Different: Types

Your tracker’s accuracy is only as good as your retroreflector. API’s Break-Resistant SMRs are constructed with a one-piece optic, eliminating the common risk of fragile glass panels shifting, separating, or fracturing. Not only are API’s SMRs durable in harsh environments, but they can track over 80 meters when used with an API laser tracker

Hollow SMRs use an aluminum optic with gold coated reflective surfaces. API’s specially surfaced SMR’s have a measurement range of up to 80m without sacrificing accuracy.

Prismatic SMRs use a solid glass prism that protects the reflective surface from dust. These types of SMR’s are suited to outdoor environments where high dust concentrations can affect accuracy.

Cleaning dust from the SMR optic with a rag or other abrasive material scratches the gold plating and diminishes SMR accuracy.

An SMR should be replaced if it is dropped. Although API’s SMRs are break-resistant, dropping an SMR can flatten out the surface of the outer ball. An SMR with a flat spot causes centering inaccuracy.

Inaccurate SMRs reduce productivity and increase operator frustration and costs. Regularly check or replace SMRs to have confidence in measurement accuracy.