- Home

- Companies

- Apoaqua Group

- Products

- Apoaqua - Model ApoPar-ZHF - Pulp Screw ...

Apoaqua - Model ApoPar-ZHF -Pulp Screw Press Machine

Cooking wastewater is a highly concentrated wastewater generated during the pulping and cooking process. This section of wastewater is very difficult to treat, including black liquor from alkaline pulping and red liquor from acid pulping.

Most paper mills use alkaline pulping. The black liquid discharged belongs to the wastewater with the highest concentration and deepest chromaticity, appearing brownish black.

Cooking wastewater concentrates almost 90% of the pollutants generated in the pulp and paper-making process. It contains a large amount of degradation products such as lignin and hemicellulose, pigments, pentose, residual alkali, and other leachable.

Its discharge amount is relatively small compared to the other two types of sewage, and about 10 tons of black liquor can be discharged for every 1 ton of pulp produced. However, this type of sewage is difficult to treat.

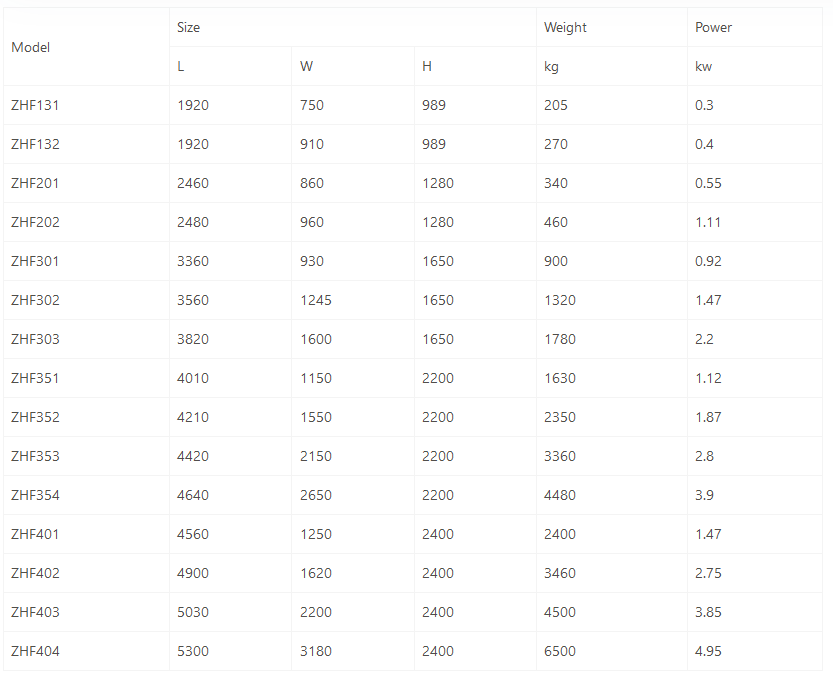

To this end, Apoaqua has developed the ApoPar-ZHF series of pulp dewatering screw press specifically designed for treating paper mill cooking wastewater.

About ApoPar-ZHF Pulp Dewatering Screw Press

- ANSYS model analysis: Using ANSYS model analysis. Adjust the screw parameters according to the characteristics of the sludge. Ensure that the product operates effectively according to the characteristics of different industries.

- Adopting a super wear-resistant hard alloy layer for overlay welding, the thickness increases by 150 times.

- ApoPar-ZHF screw press can not only treat high-concentration sludge but also directly concentrate and dehydrate low-concentration sludge. The applicable sludge concentration can reach 5000 mg/L-50000 mg/L.

- Directly perform high-pressure self-cleaning and replace the filter cloth with a movable and fixed ring. Strong oil resistance, easy to treat oily sludge.

- Rotating 2-4 revolutions per minute, the average energy consumption is 1/8 of that of a belt conveyor. 1/20 of the centrifugal machine has a unit power consumption of only 0.01-0.1kwh/kg-DS.

- The electronic control equipment adopts ABB and Shneider imported components.

- The screw press of each group of equipment are driven by independent variable frequency motors. The start is smooth, and each group can start or stop running separately.

- Small footprint allows for direct treatment of sludge from aeration tanks and secondary sedimentation tanks. No need to set up a sludge concentration tank, saving investment in supporting equipment such as mixers, air compressors, and flushing pumps.

- Combined with the automatic control system, perform program settings. Realize fully automatic control, no need for manual duty 24 hours a day.