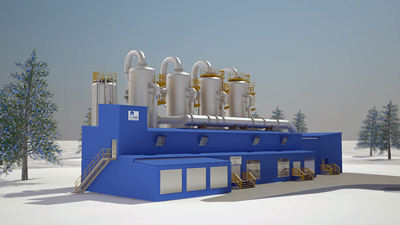

Aquatech SmartMOD - Produced Water Evaporation System

In the rugged Northern Alberta environment, installation of conventional Steam Assisted Gravity Drainage(SAGD) produced water treatment systems can be challenging. There is typically costly logistical and scheduling risks. SAGD is a technique to recover bitumen from the oil sands formation. The oil is recovered by further processing and upgrading the recovered bitumen. These formations are called Oil Sands as the bituminous resource is mixed with sand in the formation. The liquid that is brought to the surface is a mixture of oil and water. The oil and water are separated in a deoiling process. The oil is sent to Upgrader and refineries for conversion into a saleable product. The water is put through Aquatech’s produced water treatment system. Once water is purified, the water is used as feed to the boiler for generation of steam for injection into the formation and the cycle continues.

SmartMOD is an advanced water recycle solution for produced water treatment systems in the SAGD process. Innovative design transforms tall, thermal evaporator vessels into smaller modular sections that maintain vertical falling principles in addition to enhancing system performance and reliability. The evaporator is designed with a straight sump to prevent the accumulation of organics and other oily matter in the evaporator. A softening reaction vessel is designed to remove dissolved hardness upstream of the evaporator system to provide the lowest evaporator scaling rates. One of the ways performance is enhanced is with continuous distillate production with the four evaporator sections on-line during normal operation. During washing of one section, the remaining three evaporators continue to operate and maintain 100% distillate capacity. An on-line cleaning system is also provided to wash a fouled evaporator and restore clean heat transfer coefficient without needing to stop evaporation.

- Reduces total installed costs (TIC)

- Compresses overall project schedule

- Increased availability with lower downtime

- Reduces site installation work and time