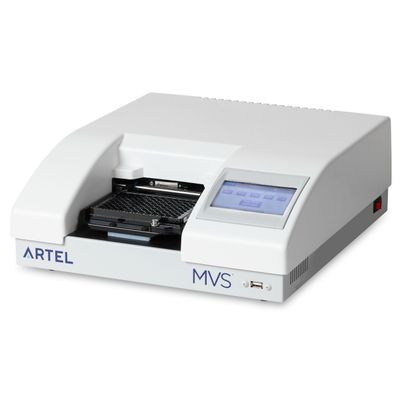

Artel MVS - Multichannel Verification System

Simple volume verification with results in less than 10 minutes. Accelerate assay optimization with an easy to use approach. Simplify regulatory compliance and be ready for audits. Verify dispensed volume of virtually all automated liquid handlers and multichannel pipettes in minutes.

- Wide Volume Measurement

- Eliminates Need for Rigorous Environmental Conditions

- Simplified Verification and Calibration

- Results Traceable to SI

The MVS’s unique, dual-dye photometric measurements are robust against environmental influences and traceable to SI units to enable comparison across operators, protocols, equipment, and locations. Using the Calibrator Plate, Verification Plates, and an Artel-certified Plate Reader, the MVS ensures a continuous chain of traceability to national and international standards.

The MVS conforms to the Dual-Dye Ratiometric Photometric Method described in ISO 23783-2:2022, and the Ratiometric Photometric Method described in ISO/IWA 15:2015 for automated liquid handling systems. It can be used to fulfill test and calibration requirements of handheld multichannel pipettes according to ISO 8655-7:2022. The MVS can be used to fulfill test and calibration requirements of handheld or automated liquid handling systems according to CLSI QMS23:2019, ISO 17025:2017, cGMP, and cGLP. ArtelWare Software can be used in laboratories compliant to 21 CFR Part 11.

Optional Compliance Suite addon features:

- unique user account credentials ensure all actions are tracked with a full audit trail

- user groups with specific privileges can be established

- new plans and plan updates require approval and are given specific version numbers

- laboratory managers can set an electronic signature requirement at any step (for full compliance with the lab’s own quality system)

- each auditable action requires audit comments when complete, and audit data is saved in secure SQL databases which may be placed on a mapped server to ensure regular back-ups

Dispense solutions

Dispense the Artel QualAssure® solution and Diluent into a Verification Plate & mix. No need to prepare in-house dyes or generate standard curves.

Read the plate

The MVS measures absorbance values and generates precise volume measurements independently in each well of the Verification Plate. No weighing is involved and environmental controls are not required.

Verify and record performance

The software automatically calculates accuracy and precision for individual volume values, for each tip or channel and provides summary statistics by well, row, and column. Results are stored in ArtelWare, and reports are ready to print or export.

System Performance with 96 well MVS Verification Plate

- Time Requirements: < 5 Minutes

- Tip Configurations: 1, 2, 4, 6, 8, 12, and 96

- Traceable Volume Range: 0.1000 - 350.0μL

- Operating Volume Range: 0.0001 - 350 μL

- Operating Temperature: 15 - 30° C

- Traceability to national & international standards: Yes

System Performance with 384 well MVS Verification Plate

- Time Requirements: < 10 Minutes

- Tip Configurations: 1, 8, 12, 16, 24, 96,

- and 384

- Traceable Volume Range: 0.0100 - 55.00μL

- Operating Volume Range: 0.0001 - 55.00μL

- Operating Temperature: 15 - 30° C

- Traceability to national & international standards: Yes

MVS Computer (recommended minimum requirements)

- Processor: x64 Processor: 2.4 GHz (recommended 4 or more cores)

- Memory: 4 GB (recommended min. 16GB)

- I/O Ports: 3 USB Connectors

- Network: Gigabit Ethernet or 802.11n wifi

- Storage: 40 GB of hard drive space

- Supported Operating Systems: Windows® 10 or Windows® 11

- SQL Server: 2019, 2017, 2016, and 2014

- in Express, Standard

- and Enterprise Editions

ARTEL 800TSNB PLATE READER

- Dimensions (DxWxH): 41.9 x 38.1 x 17.8 cm

- Weight: 9.97 kg

- Display: Touch screen

- Light source: Tungsten gas filled bulb

- Wavelength selection: Metal oxide interference filters

- Center wavelengths:

- 520.2 nm (bandwidth at half-max = 6.2 nm)

- 730.5 nm (bandwidth at half-max = 10 nm)

- Additional filters: 405 nm, 450 nm, 490 nm

- COM Port: USB

- Power requirements: Voltage: 90 – 260 VAC

- Frequency: 50 – 60 Hz

- Current: 2 A maximum

MVS TITER PLATE SHAKER

- Dimensions (DxWxH): 142 x 99 x 48.2 mm

- Amplitude: 2.0 mm orbital

- Shaking speed range: 200 to 3000 rpm

- Power requirements: External power supply

- 100-240 V AC

- 50-60 Hz

MVS CALIBRATOR PLATE

- Storage Temperature: 15 - 25 °C in protective case

- out of direct light

- Operation Temperature: 15 - 30 °C

- Recalibration: 12 month factory

- recalibration required

- Shelf life: 1 year

MVS BAR CODE READER

- Dimensions (LxWxH): 104 x 71 x 160 mm

- Weight: 147 g