Artesis - Model AMT Pro -Rotating Equipment Tester without Sensors

The Artesis AMT Pro is a portable motor driven equipment test system which automatically generates a condition assessment report indicating existing electrical mechanical and operational faults, time to failure information, recommended corrective actions, and effects of faults on energy efficiency.

- Immediate payback by corrective action

- Instant condition assessment report

- Advanced analysis and reporting

- No sensors on motor or equipment

- Improved efficiency and reliability of plant & processes

- Increased machine availability

- Advanced spectrum and waveform tools

- Immediate report generation with actionable information

- Access to hard to reach applications

- Cloud integration

AMT Pro is compatible with, 3 phase AC Motor of fixed and varibable speed, Generators, Compressors, Fans, Pumps, Conveyors, Motor Driven Equipment

- Automated Fault Diagnosis

- Immediate report generation with actionable information

- Advanced spectrum and waveform tools

- Access to hard to reach applications

- Cloud integration (wifi)

- Short test time (7 min)

- Simple and easy test procedure

- Live motor testing

- Portable, battery powered

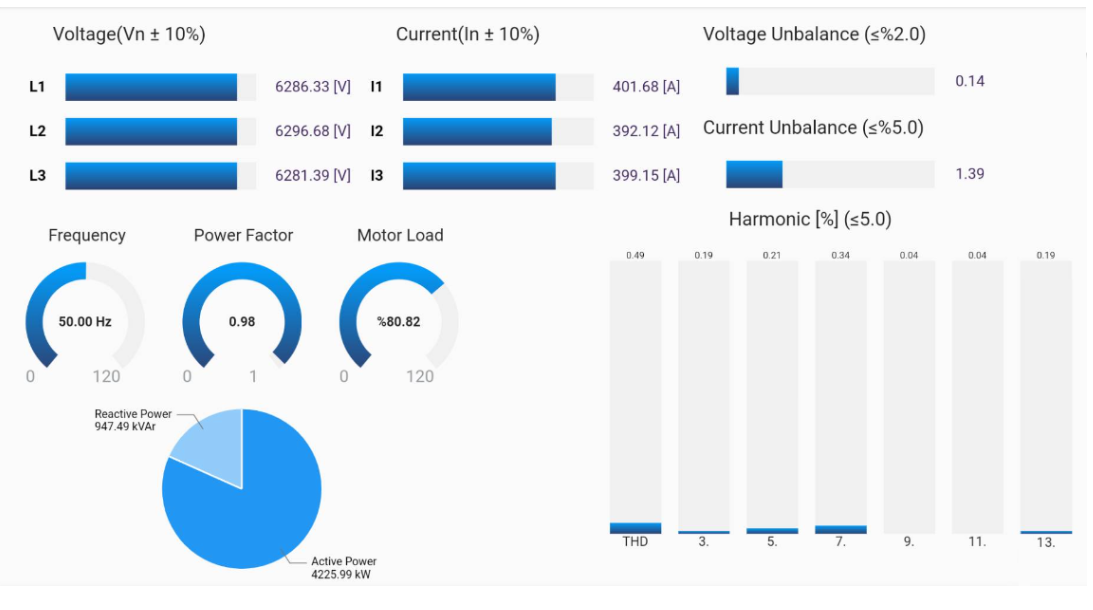

AMT Pro measures 3 phase Voltage and 3 phase current at 2500 Hz sampling rate.Motor tests are completed in 7 minutes. yielding to an automatic test report indicating motor health with barcharts, list of electrical parameters and PSD (Power Spectral Density) results. The test results simultaneously sync to the secure cloud-based server allowing access to the reports on an IoT platform.

Stator

- Interturn short circuit (the early phase of turn-to-turn short circuit)

- Phase-to-phase short circuit

- Impedance unbalance or shift

- Insulation degradation

- Soft foot (stator deformation)

- Loose foot (bolt loose)

- Winding overheating

- Winding looseness

- Lamination looseness

- Unbalance (fan, shaft deformation)

- Thermal bow (unbalance)

- Static and dynamic eccentricity

- Rubbing

- Severe porosity

- Angular and parallel misalignment

- Broken, damaged and loose rotor bars

- Overheating

- Winding looseness

- Lamination looseness

- Damping cage degradation

- PM degradation

- Outer & inner race pitting

- Ball/roller wear

- Cage/raceway deformation

- Cocked bearing

- Grease contamination

- Over greasing

- Bearing creep/skidding

- False & true brinelling

- Plain bearing oil whirl and whip

- Plain bearing radial preload

- Plain bearing rotor rub

- Outer & inner race pitting

- Ball/roller wear

- Cage/raceway deformation

- Cocked bearing

- Grease contamination

- Over greasing

- Bearing creep/skidding

- False & true brinelling

- Plain bearing oil whirl and whip

- Plain bearing radial preload

- Plain bearing rotor rub

- Broken teeth/claws

- Looseness

- Excessive clearance

- Eccentricity

- Unbalance

- Mesh quality

- Backlash

- Misalignment

- Assembly phase problems

- Hunting tooth frequency

- High energy consumption

- Low efficiency

- Cavitation in pumps

- Flow turbulence in fans, blowers

- Filter and heat exchanger fouling

- Lubrication

- Oversize/undersize motors