- Home

- Companies

- Ash Environmental Technologies

- Products

- AshTech - Effluent Sewers Systems

AshTech - Effluent Sewers Systems

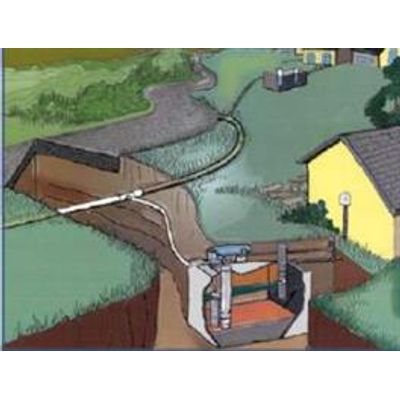

Effluent sewers are a more efficient and cost effective method of conveying sewage from multiple homes and premises to a treatment facility than gravity sewers. They are a viable option for many unserviced communities currently without sewer systems.

What are Effluent Sewers?

Sewage from each premises is piped to an interceptor septic tank which screens the effluent retaining the solid particles in the tank for de-sludging. The screened effluent is either pumped or flows by gravity to the pressurised PVC sewer line and from there to the location of the decentralised treatment system.

An Effluent Sewer is a collection technology that has been optimised for more than 30 years in the US, Australia and elsewhere.

Ash Environmental supported by Orenco

A US based engineering company Orenco pioneered the use of effluent sewers in the US in the 1980’s. Orenco have teamed up with Ashtecs in Ireland and in the UK to provide technical and engineering support for the technology design, installation and long term operation of the collection networks.

How does it Work?

The sewage flows from the building to a watertight underground tank, where primary treatment occurs via settling and natural biological processes. Solids remain in the tank, decreasing in volume, which reduces biosolids treatment costs at secondary treatment facilities. Filtered liquid effluent is then discharged by head pump or gravity through small-diameter PVC service pipes to small-diameter PVC collection lines. These service and collection lines are shallow buried and follow the contour of the land. The entire system is watertight, reducing infiltration costs in conveyance and at the treatment facility. No manholes or lift stations are required and energy consumption is minimal..

Small-diameter pipes can be used with pressure sewers because large and solid materials in the wastewater are separated out or ground up in initial treatment. The pipes are usually made of plastic, which gives them the advantage of being more flexible and more likely to remain watertight than sewers made of clay or concrete. Watertightness is important to maintaining pressurisation. The pressure in pressure sewers is created by the wastewater being pumped into the pipes at several connections. The pressurised lines eliminate the need for gravity as a force to move the wastewater to its destination. Because of this, the pipe can be laid to follow the natural contour of the land in shallow trenches just below the frost line and deep enough to be kept safe from the traffic above.